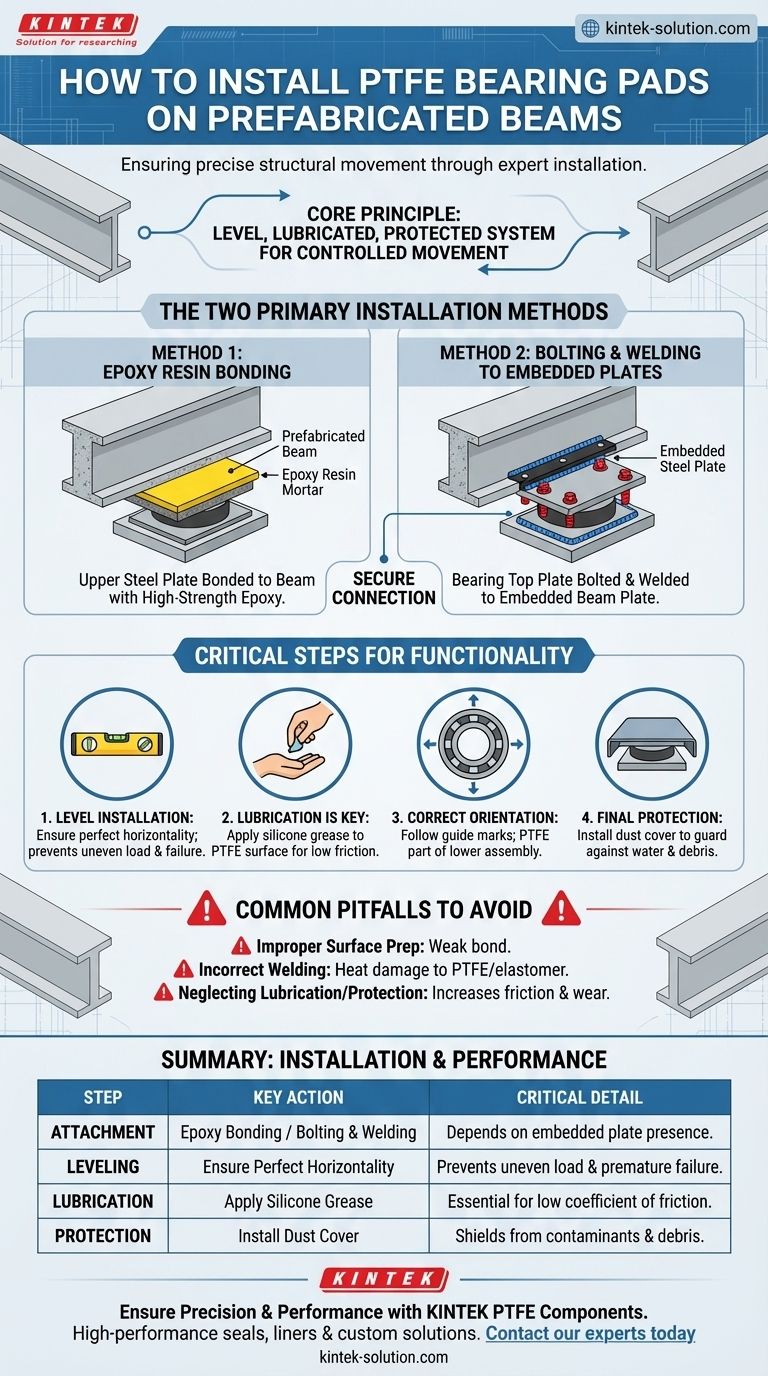

To install a PTFE bearing pad on a prefabricated beam, the primary methods involve either bonding the bearing's upper steel plate directly to the beam's underside with epoxy resin mortar or, if the beam has an embedded steel plate, connecting it via bolting and welding. This connection is just one part of a precise process that ensures the bearing accommodates structural movement correctly.

The core principle of a successful PTFE bearing installation is not just about attachment, but about creating a perfectly level, lubricated, and protected system that allows for controlled, low-friction movement as the structure expands and contracts.

The Two Primary Installation Methods

For prefabricated beams, the method of attachment depends entirely on whether the beam was cast with an embedded steel plate at the bearing location.

Method 1: Bonding with Epoxy Resin Mortar

This is the standard approach when the underside of the concrete beam is the direct contact point.

The upper steel plate of the bearing assembly is bonded directly to the prepared surface of the prefabricated beam using a high-strength epoxy resin mortar. This creates a powerful, monolithic connection.

Method 2: Bolting and Welding to Embedded Plates

This method is used when a steel plate has already been cast into the bottom of the prefabricated beam.

The bearing's top plate is placed against the beam's embedded plate. The two are then joined together using a combination of high-strength bolts and perimeter welding to ensure a secure and rigid connection.

Critical Steps for Correct Functionality

Attaching the bearing is only the first step. Proper function depends on several other critical details during the installation process.

Ensuring a Level Installation

The entire bearing assembly must be installed perfectly horizontally. Any deviation can lead to uneven load distribution, edge compression, and a significant reduction in the bearing's performance and lifespan.

The Role of Lubrication

Before the final placement, silicone grease must be applied evenly between the PTFE surface and the mating stainless steel plate. This lubrication is essential for achieving the extremely low coefficient of friction that allows the structure to move freely.

Correct Orientation and Placement

The bearing assembly has a specific orientation. The installation direction must follow the guide marks on the bearing's stop plate to ensure it accommodates movement along the correct axis. The PTFE board is part of the lower assembly and should never be placed directly on the bridge pier.

Final Protection

After the beam is set and the bearing is in place, a dust cover must be installed. This cover protects the lubricated sliding surfaces from water, debris, and other contaminants that could increase friction and cause premature wear.

Common Pitfalls to Avoid

Mistakes during installation can compromise the entire system and lead to costly remediation.

Improper Surface Preparation

For epoxy bonding, the concrete surface of the beam must be meticulously cleaned and prepared. Any laitance, dust, or moisture will result in a weak bond that could fail under load.

Incorrect Welding Procedures

When welding the bearing plate to an embedded plate, excessive heat can damage the internal elastomeric or PTFE components of the bearing. Proper heat control and welding procedures are critical to avoid compromising the materials.

Neglecting Lubrication or Protection

Forgetting to apply silicone grease or failing to install the dust cover are two of the most damaging errors. These omissions turn a low-friction bearing into a high-friction surface, defeating its primary purpose and inducing unwanted stress into the structure.

Making the Right Choice for Your Goal

The installation process must be executed with precision to meet the engineering requirements.

- If your primary focus is creating a secure connection: Your choice between epoxy bonding and welding is determined by the beam's design—specifically, the presence or absence of an embedded steel plate.

- If your primary focus is ensuring long-term structural performance: You must prioritize the procedural details of leveling, lubrication, correct orientation, and final protection with a dust cover.

Ultimately, a successful installation depends on treating the bearing not as a simple component, but as an engineered system requiring meticulous attention to detail.

Summary Table:

| Installation Step | Key Action | Critical Detail |

|---|---|---|

| Attachment Method | Epoxy Bonding or Bolting/Welding | Depends on presence of an embedded steel plate in the beam. |

| Leveling | Ensure perfect horizontality | Prevents uneven load distribution and premature failure. |

| Lubrication | Apply silicone grease to PTFE surface | Essential for achieving the required low coefficient of friction. |

| Protection | Install dust cover | Shields sliding surfaces from contaminants like water and debris. |

Ensure Precision and Performance with KINTEK PTFE Components

A flawless PTFE bearing installation is critical for the safety and longevity of your structure. The precision required for these components—from the PTFE surface itself to the seals and protective elements—is our specialty at KINTEK.

We manufacture high-performance, custom-fabricated PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our commitment to precision production ensures your components meet the most demanding specifications.

Let us provide the reliable PTFE solutions your project demands. Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications