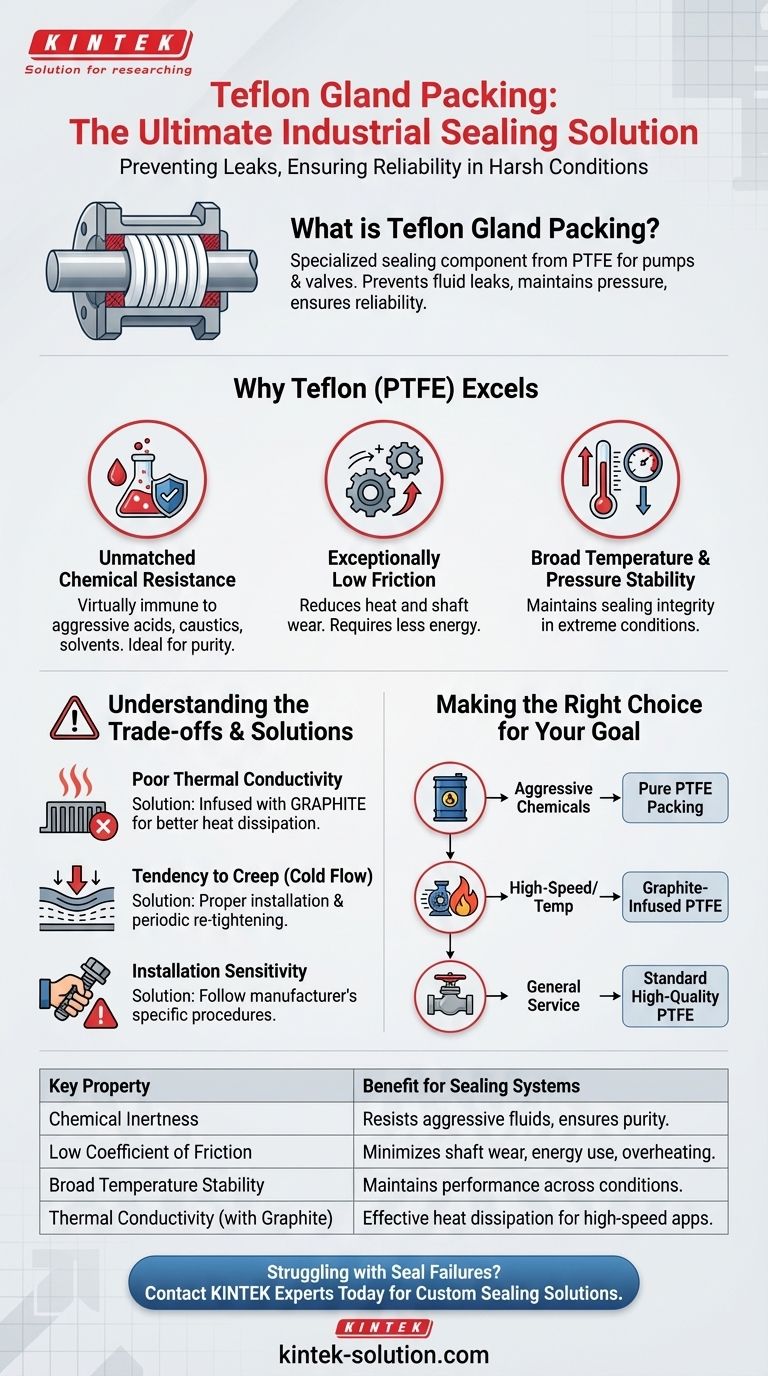

In industrial environments, Teflon gland packing is a specialized sealing component used within the stuffing boxes of pumps and valves. It is crafted from Polytetrafluoroethylene (PTFE) fibers and is essential for preventing fluid leaks, maintaining system pressure, and ensuring equipment reliability under chemically aggressive and high-temperature conditions.

The true importance of Teflon gland packing lies not just in creating a seal, but in its unique combination of near-universal chemical inertness and an extremely low coefficient of friction. This pairing ensures operational longevity and safety where most other materials would rapidly degrade or cause equipment damage.

The Fundamental Role of Gland Packing

Gland packing is the workhorse of dynamic sealing in countless industrial applications. Its function is straightforward but critical: to control leakage where a moving part (like a rotating shaft or a valve stem) passes through a stationary housing.

A Dynamic, Controlled Seal

The packing material is compressed within a "stuffing box" around the shaft. This compression creates a seal against the internal pressure of the fluid being handled.

It's a common misconception that the goal is a zero-leak seal. In many pump applications, a very slight, controlled leak is intentional to provide lubrication and cooling to the packing and the shaft.

Preventing Catastrophic Failure

Effective gland packing is a pillar of industrial safety and efficiency. It contains the process fluid, prevents the loss of valuable product, and protects personnel and the environment from hazardous leaks.

A failure in the packing can lead to costly downtime, equipment damage, and significant safety incidents.

Why Teflon (PTFE) Excels as a Packing Material

While many fiber materials can be used for gland packing, Teflon (PTFE) possesses a set of properties that make it a superior choice for demanding services.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert substances known. It is virtually immune to attack from aggressive acids, caustics, solvents, and other corrosive fluids that would destroy conventional packing materials.

This makes it the default choice in chemical processing, pharmaceuticals, and food and beverage industries where product purity and material compatibility are paramount.

Exceptionally Low Friction

Teflon has an incredibly low coefficient of friction, one of the lowest of any solid material. This is a massive advantage in sealing applications.

Low friction means less heat is generated at the shaft, reducing the risk of overheating. It also minimizes wear on the expensive pump shaft or valve stem and requires less energy to operate the equipment.

Broad Temperature and Pressure Stability

Teflon gland packing can operate effectively across a wide range of temperatures and pressures, maintaining its sealing integrity and physical properties where other materials would become brittle or soft.

Understanding the Trade-offs

No material is perfect, and a trusted advisor must highlight the limitations. Understanding these trade-offs is key to successful application and installation.

Poor Thermal Conductivity

While Teflon generates little friction, it is also a poor conductor of heat. In very high-speed pump applications, the heat that is generated may not dissipate quickly enough, potentially damaging the packing.

To counteract this, many Teflon packings are impregnated with materials like graphite, which significantly improves thermal conductivity.

Tendency to 'Creep'

Under sustained pressure and temperature, PTFE has a tendency to cold flow, or "creep." This means it can slowly deform over time, which may cause the seal to loosen.

Proper installation technique and periodic re-tightening of the gland follower are essential to manage this characteristic and maintain an effective seal.

Installation Sensitivity

The performance of Teflon packing is highly dependent on correct installation. Overtightening is a common mistake that can crush the packing, extrude it out of the stuffing box, and drastically increase friction and shaft wear.

Following the manufacturer's specific installation procedures is not just recommended; it is critical for achieving a long and reliable service life.

Making the Right Choice for Your Goal

Selecting the correct packing involves matching the material to the specific demands of your equipment and process fluid.

- If your primary focus is handling aggressive chemicals: Pure PTFE packing is the ideal choice due to its unparalleled chemical inertness.

- If your primary focus is high-speed pumps or high temperatures: Select a PTFE packing infused with graphite to improve heat dissipation and prevent thermal damage.

- If your primary focus is general service in valves and slower pumps: A standard, high-quality PTFE packing provides an excellent balance of sealing performance, low friction, and long service life.

Ultimately, selecting the correct gland packing is a foundational decision that directly impacts the safety, efficiency, and reliability of your entire fluid handling system.

Summary Table:

| Key Property | Benefit for Sealing Systems |

|---|---|

| Chemical Inertness | Resists aggressive acids, caustics, and solvents, ensuring purity and compatibility. |

| Low Coefficient of Friction | Minimizes shaft wear, reduces operating energy, and prevents overheating. |

| Broad Temperature Stability | Maintains integrity and performance across a wide range of operating conditions. |

| Consideration: Thermal Conductivity | May require graphite infusion for high-speed applications to dissipate heat effectively. |

Struggling with seal failures in aggressive chemical or high-temperature processes? KINTEK specializes in manufacturing high-performance, precision PTFE components like gland packing, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to ensure your equipment runs safely and efficiently. Contact our experts today to discuss a sealing solution tailored to your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications