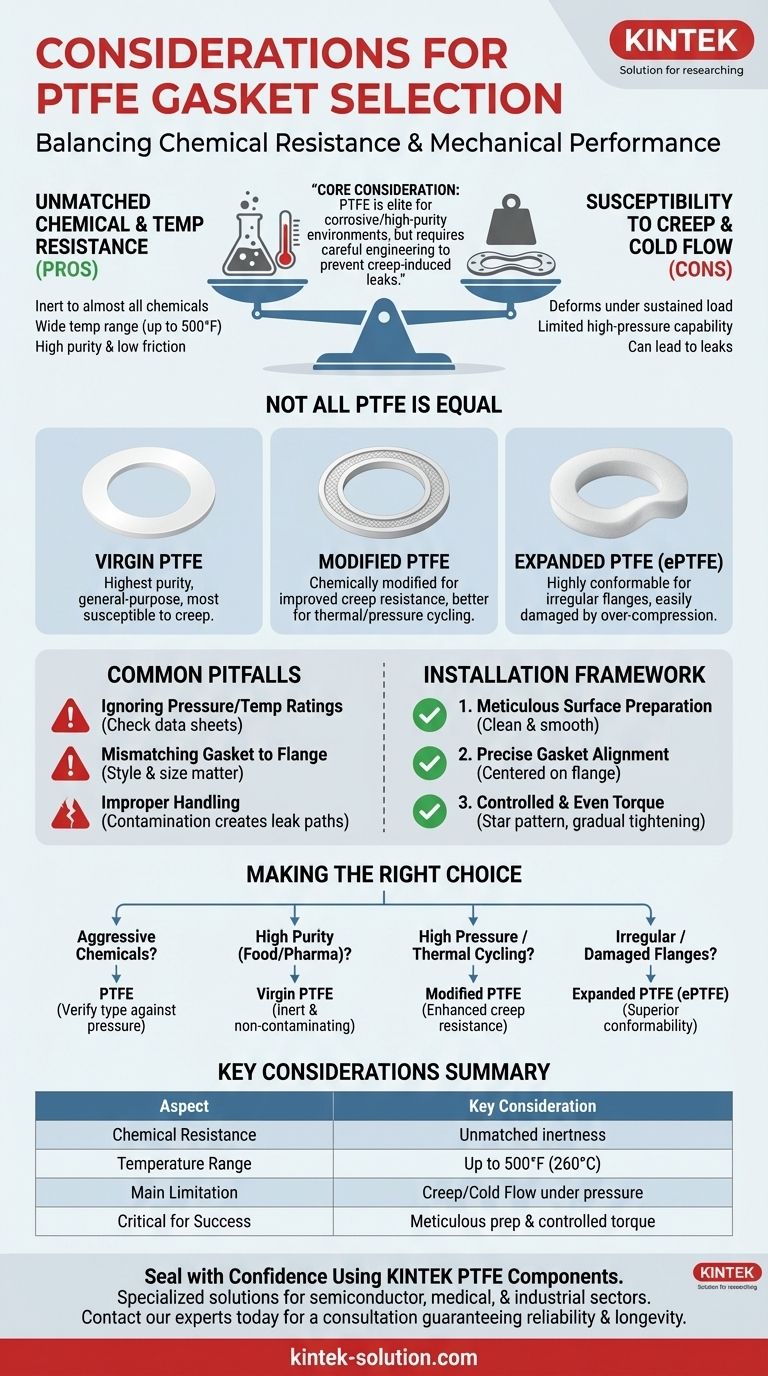

When choosing a PTFE gasket, the decision hinges on a critical trade-off. You must balance its unparalleled resistance to chemicals and extreme temperatures against its inherent mechanical weaknesses, specifically its tendency to deform under pressure, a phenomenon known as "creep" or "cold flow."

The core consideration is this: PTFE is an elite sealing material for corrosive or high-purity environments, but its physical softness requires careful engineering and meticulous installation to prevent leaks, especially in high-pressure or high-stress applications.

Evaluating the Core Properties of PTFE

To make an informed decision, you must understand both the distinct advantages and the critical limitations of Polytetrafluoroethylene (PTFE) as a gasket material.

Pro: Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. This makes it the default choice for sealing systems that handle aggressive acids, solvents, and caustics where other materials would quickly degrade.

Pro: Wide Operating Temperature Range

Standard PTFE gaskets perform reliably across a broad temperature spectrum, typically handling services up to 500°F (260°C). This stability makes them suitable for a wide variety of industrial processes.

Pro: Purity and Low Friction

PTFE has an exceptionally low-friction, non-stick surface. This property, combined with its inertness, prevents contamination, making it ideal for applications in the food, beverage, and pharmaceutical industries.

Con: Susceptibility to Creep (Cold Flow)

This is PTFE's most significant drawback. Under sustained compressive load, especially at elevated temperatures, the material will slowly deform or "flow" away from the pressure point. This relaxation can lead to a loss of bolt torque and, ultimately, a leak.

Con: Limited High-Pressure Capability

Directly related to creep, PTFE's softness makes it less suitable for very high-pressure applications compared to metallic or composite gaskets. The high mechanical load can accelerate cold flow and cause the gasket to extrude from the flange.

Not All PTFE Is Created Equal

The term "PTFE gasket" refers to a family of materials. The specific type you choose has a major impact on its performance, particularly its resistance to creep.

Virgin PTFE

This is the pure, unfilled grade of PTFE. It offers the highest level of chemical purity and is a good general-purpose choice, but it is also the most susceptible to cold flow.

Modified PTFE

These gaskets are made from a chemically modified PTFE structure that significantly improves resistance to creep and cold flow. They offer a much better performance profile for more demanding thermal and pressure cycling applications.

Expanded PTFE (ePTFE)

This form of PTFE is soft and highly conformable. It is exceptionally good at sealing old, damaged, or irregular flange surfaces because it can fill in imperfections. However, it is very soft and can be easily damaged by over-compression during installation.

Understanding the Trade-offs and Common Pitfalls

Successful sealing with PTFE is as much about avoiding errors as it is about leveraging the material's strengths. Failure often stems from a misunderstanding of its limitations.

Ignoring Pressure and Temperature Ratings

Never assume PTFE is universally applicable. Always cross-reference the application's maximum pressure and temperature with the specific gasket's data sheet. Exceeding these limits is a primary cause of failure.

Mismatching the Gasket to the Flange

Using the wrong size is an obvious error, but the style is also critical. An irregular or pitted flange that might cause a leak with a rigid virgin PTFE gasket could be perfectly sealed with a conformable ePTFE sheet.

Improper Handling and Contamination

The surface of a PTFE gasket is critical to its sealing performance. Always use clean gloves when handling them. Scratches or contamination from dirt and oils on your hands can create a leak path and lead to premature failure.

A Framework for Proper Installation

A perfect gasket choice can be nullified by poor installation. A methodical approach is non-negotiable for achieving a reliable seal.

Step 1: Meticulous Surface Preparation

Both flange faces must be completely clean and free of old gasket material, rust, or other debris. The cleaner the surface, the more effective the seal.

Step 2: Precise Gasket Alignment

Ensure the gasket is perfectly centered on the flange face. An off-center gasket will receive uneven compressive force, creating a weak point and a potential leak path.

Step 3: Controlled and Even Torque Application

Bolts must be tightened gradually and in a star or crisscross pattern to distribute the load evenly. Over-tightening is a major error; it will crush the gasket, dramatically accelerate cold flow, and cause the seal to fail.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical demand of your system.

- If your primary focus is aggressive chemical compatibility: PTFE is likely your best choice, but verify the specific type (virgin vs. modified) against your pressure requirements.

- If your primary focus is high-purity applications (food, pharma): Virgin PTFE is an excellent default due to its inherent inertness and non-contaminating properties.

- If your primary focus is high pressure or thermal cycling: You must specify a modified PTFE gasket designed for enhanced creep resistance to ensure a durable, long-term seal.

- If your primary focus is sealing irregular or damaged flanges: Expanded PTFE (ePTFE) offers superior conformability but requires careful installation to avoid over-compression.

By carefully matching the right type of PTFE to your application and adhering to strict installation protocols, you can leverage its unique strengths to achieve a safe and reliable seal.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Chemical Resistance | Unmatched inertness; ideal for aggressive acids and solvents. |

| Temperature Range | Broad operational range, typically up to 500°F (260°C). |

| Main Limitation | Susceptible to creep/cold flow under sustained pressure. |

| Material Types | Virgin PTFE (pure), Modified PTFE (creep-resistant), ePTFE (conformable). |

| Critical for Success | Requires meticulous flange preparation and controlled bolt torque during installation. |

Seal with Confidence Using KINTEK PTFE Components

Choosing the right PTFE gasket is critical for the safety and efficiency of your operations in the semiconductor, medical, laboratory, and industrial sectors. KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—designed to meet the exacting demands of specialized applications.

We understand the delicate balance between chemical resistance and mechanical performance. Our expertise ensures you get a solution tailored to your specific pressure, temperature, and purity requirements, from prototypes to high-volume orders.

Don't let sealing challenges compromise your process. Contact our experts today for a consultation and let us provide you with a PTFE solution that guarantees reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers