In the chemical processing industry, PTFE rubber seals are critical components used to prevent leaks in systems handling highly reactive or corrosive chemicals. They are primarily utilized in dynamic and static applications like pumps, valves, pipelines, and flanged connections to ensure operational safety, prevent contamination, and protect equipment from degradation.

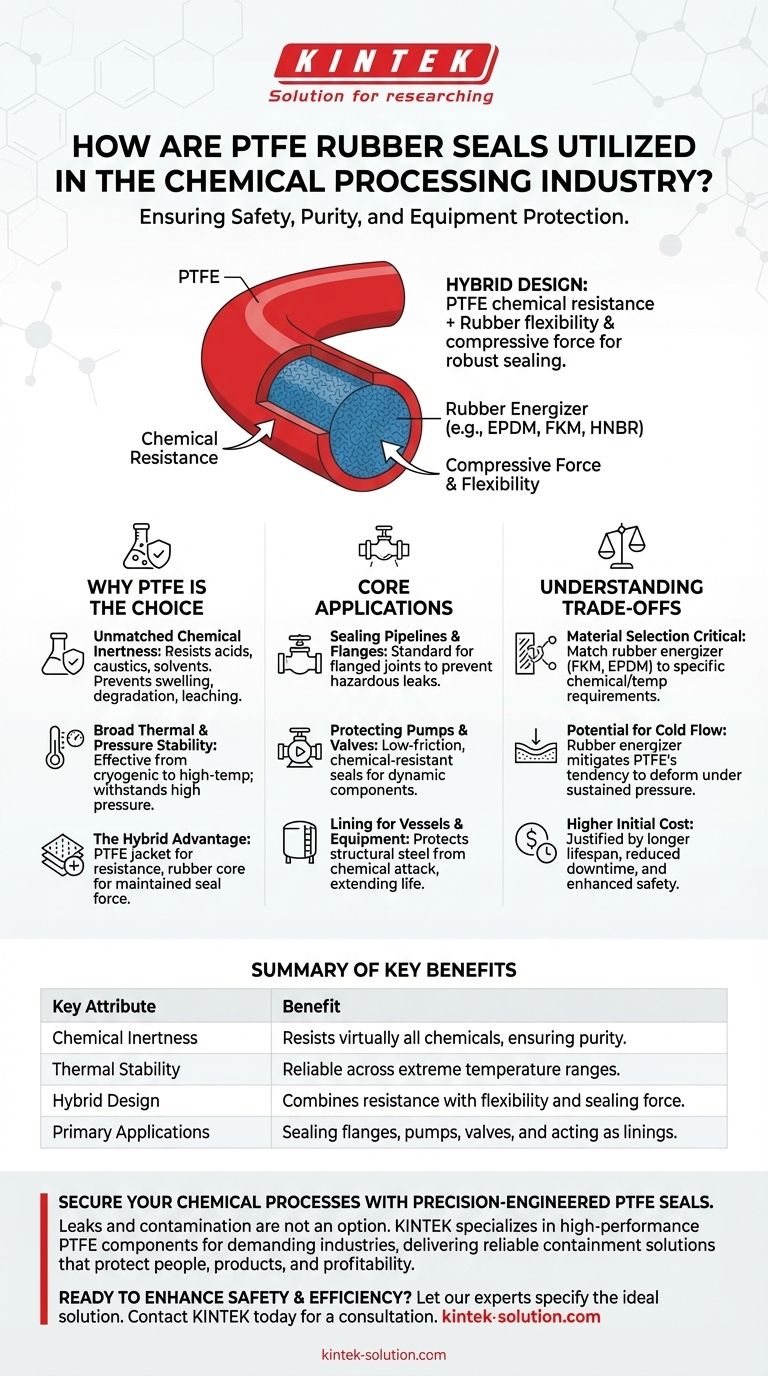

The core value of a PTFE rubber seal lies in its hybrid design. It combines the near-universal chemical inertness and temperature resistance of PTFE with the flexibility and compressive force of a rubber core, creating a robust sealing solution for environments where conventional materials would quickly fail.

Why PTFE is the Material of Choice

The selection of a sealing material in chemical processing is not trivial; it is a fundamental decision that impacts safety, product purity, and equipment lifespan. PTFE (Polytetrafluoroethylene) possesses a unique combination of properties that makes it exceptionally suited for these demanding applications.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all industrial chemicals, acids, and caustic substances. This inertness means the seal will not swell, degrade, or leach contaminants into the process fluid, which is critical for maintaining product purity and ensuring the seal's structural integrity over time.

Broad Thermal and Pressure Stability

These seals can function effectively across an exceptionally wide range of temperatures, from cryogenic applications like liquefied natural gas (LNG) systems to high-temperature petrochemical plants. Their ability to also withstand high-pressure environments makes them a versatile solution for many complex industrial processes.

The Hybrid Advantage: PTFE and Rubber

A PTFE rubber seal is a composite component. A PTFE jacket or layer provides the chemically resistant contact surface. This is bonded to a rubber energizer or core, often made from materials like EPDM, FKM, or HNBR. The rubber provides the constant compressive force and flexibility needed to maintain a tight, reliable seal, even with minor flange imperfections or pressure fluctuations.

Core Applications in Chemical Plants

Within a chemical processing facility, you will find PTFE seals deployed at virtually every critical fluid handling point to guarantee containment and prevent fugitive emissions.

Sealing Pipelines and Flanges

PTFE gaskets are the industry standard for sealing flanged joints in pipelines that transport aggressive chemicals. They create a tight barrier between flange faces, preventing leaks that could be hazardous to personnel and the environment.

Protecting Pumps and Valves

In dynamic equipment like pumps and valves, seals are subjected to constant movement, pressure changes, and friction. PTFE seals provide the low-friction surface and chemical resistance needed to ensure these components operate efficiently and safely without leaking corrosive media.

Lining for Vessels and Equipment

Beyond seals, PTFE is often used as a lining for tanks, vessels, and pipes. This application follows the same principle: using PTFE's inert properties to protect the structural steel of the equipment from chemical attack, thereby extending its service life and ensuring process safety.

Understanding the Trade-offs

While highly effective, choosing PTFE seals requires a clear understanding of their characteristics to ensure proper application and avoid potential issues.

Material Selection is Critical

The term "PTFE rubber seal" is broad. The performance of the seal is heavily dependent on the choice of the rubber energizer. For instance, an FKM core is excellent for high temperatures and chemical resistance, while an EPDM core might be chosen for other specific chemical compatibilities. Mismatching the rubber to the application can lead to failure.

Potential for Cold Flow (Creep)

PTFE, particularly in its pure form, can exhibit "cold flow" or creep—a tendency to deform permanently under sustained pressure and temperature. The rubber energizer in a composite seal is crucial for mitigating this, as it provides elastic recovery that helps the seal maintain its force.

Higher Initial Cost

PTFE seals typically have a higher upfront cost compared to standard elastomeric seals. However, this cost is almost always justified by their significantly longer service life, reduced maintenance downtime, and the enhanced safety they provide in critical applications.

Making the Right Choice for Your Process

Selecting the appropriate seal is a matter of matching the material's properties to the specific demands of your chemical process.

- If your primary focus is handling highly corrosive acids or solvents: A seal with a PTFE contact surface is essential to prevent chemical degradation and ensure long-term reliability.

- If your process involves extreme temperature ranges or high pressure: Verify that both the PTFE and the specific rubber core are rated for your operating window to prevent seal failure.

- If you are prioritizing system safety and leak prevention: The superior reliability and longevity of a PTFE composite seal justify the investment to prevent costly failures, environmental hazards, and unscheduled downtime.

Ultimately, specifying the right PTFE seal is a critical step in designing a safe, reliable, and efficient chemical processing system.

Summary Table:

| Key Attribute | Benefit in Chemical Processing |

|---|---|

| Chemical Inertness | Resists virtually all acids, caustics, and solvents, ensuring product purity. |

| Thermal Stability | Performs reliably from cryogenic to high-temperature applications. |

| Hybrid Design | Combines PTFE's chemical resistance with a rubber core's flexibility and sealing force. |

| Primary Applications | Sealing flanges, pumps, valves, and acting as linings for vessels and pipes. |

Secure Your Chemical Processes with Precision-Engineered PTFE Seals

Leaks and contamination are not an option in your chemical processing operations. The right PTFE rubber seal is critical for ensuring long-term equipment integrity, operational safety, and preventing costly downtime.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom seals, liners, and labware, for the most demanding industries. We understand the precise material science required to match the perfect PTFE and rubber composite to your specific chemical, temperature, and pressure requirements.

We provide more than just parts; we deliver reliable containment solutions that protect your people, your product, and your profitability.

Ready to enhance the safety and efficiency of your system? Let our experts help you specify the ideal sealing solution.

Contact KINTEK today for a consultation to discuss your application needs, from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How can AI and machine learning improve CNC machining processes for PTFE parts? Boost Precision & Reduce Waste

- What are the core material options for PTFE encapsulated O-rings? Choose Viton® or Silicone for Your Sealing Needs

- What are the key takeaways when comparing FR4 and PTFE laminates? Choosing the Right PCB Material for Your Application

- What are the overall benefits of using PTFE expansion bellows? Prevent Pipe Failure and Reduce Downtime

- How do PTFE O-rings function? A Guide to High-Performance Sealing in Demanding Environments

- What are the machining concerns for PTFE wear plates? Overcome Thermal Expansion & Tool Wear

- How is graphite filler typically used in PTFE? Enhance Wear Resistance & Self-Lubrication

- What factors should be considered when selecting a PTFE Expansion Bellow? Ensure Safety and Reliability