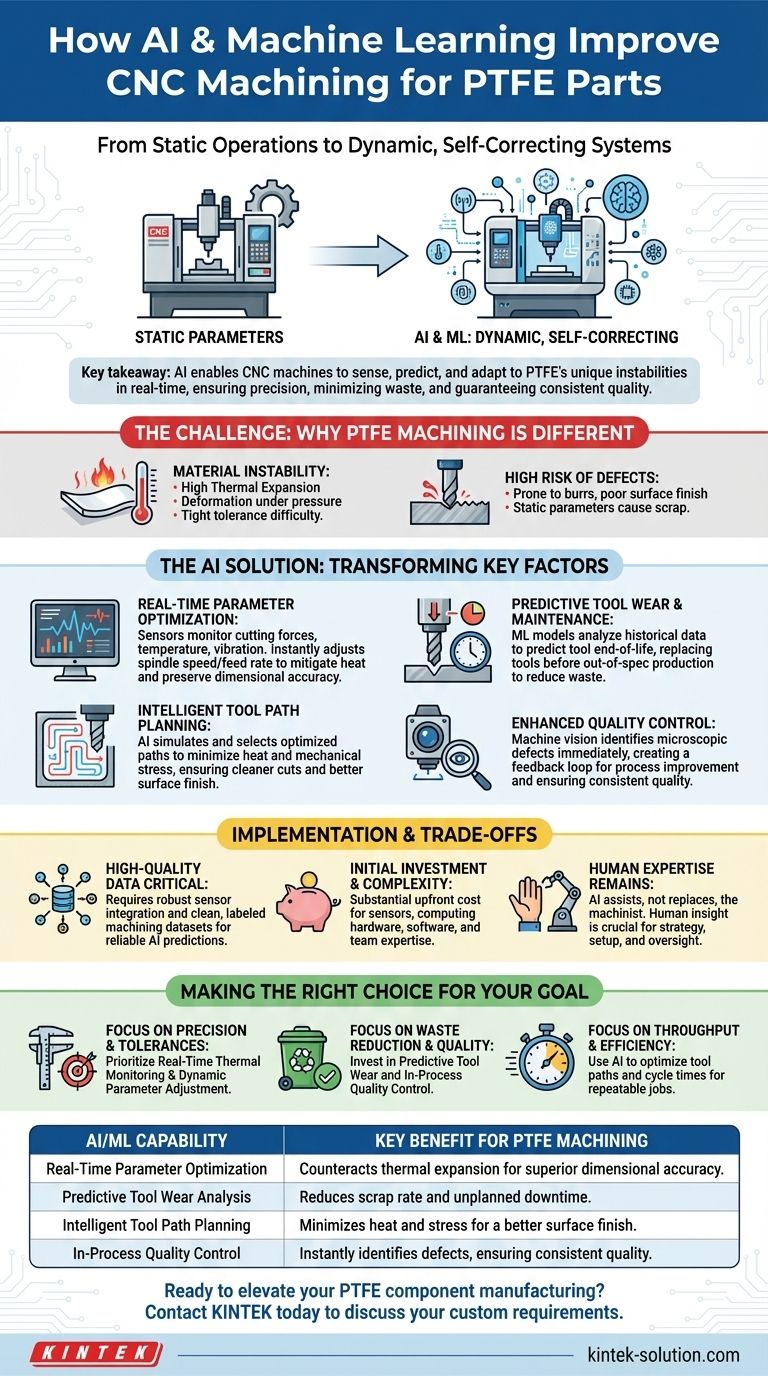

To be direct, AI and machine learning fundamentally improve CNC machining for Polytetrafluoroethylene (PTFE) parts by transforming the process from a static, pre-programmed operation into a dynamic, self-correcting system. These technologies enable real-time optimization of critical machining parameters, directly counteracting PTFE's challenging properties to enhance precision, minimize material waste, and ensure consistent quality.

The central takeaway is that AI and machine learning are not just about automation; they are about giving a CNC machine the ability to sense, predict, and adapt to the unique instabilities of PTFE during the cutting process, something a fixed set of instructions cannot achieve.

The Core Challenge: Why PTFE Machining is Different

Before understanding the solution, we must respect the problem. PTFE is notoriously difficult to machine due to its unique physical properties, which traditional CNC methods struggle to manage consistently.

The Problem of Material Instability

PTFE is a soft material with a very high coefficient of thermal expansion. Even slight temperature increases from tool friction can cause the material to expand, move, or warp mid-process.

This instability makes holding tight tolerances a significant challenge, as the part's dimensions can change during the cut.

The High Risk of Defects

The softness of PTFE also means it is prone to developing burrs and a poor surface finish if cutting parameters are not perfect. The material can deform under tool pressure rather than shearing cleanly.

Traditional CNC programming relies on static, pre-set parameters that cannot account for these real-time variations.

The Limits of Static Parameters

A machinist programs speeds and feeds based on experience and best practices. However, these settings are fixed and cannot adapt to factors like subtle changes in material density, ambient temperature, or the gradual dulling of a cutting tool.

This static approach often leads to a higher scrap rate and requires significant operator oversight to make manual adjustments.

How AI Transforms Key Machining Factors

AI and machine learning introduce a layer of intelligence that monitors the key variables of the machining process and makes adaptive changes on the fly.

Real-Time Parameter Optimization

AI systems use sensors to monitor factors like cutting forces, vibration, and workpiece temperature in real time.

If the system detects a temperature rise that could cause thermal expansion, it can instantly adjust the spindle speed and feed rate to mitigate the heat buildup, preserving the part's dimensional accuracy.

Predictive Tool Wear and Maintenance

Machine learning models can analyze data from past machining runs to predict when a cutting tool is nearing the end of its effective life.

This allows for predictive maintenance, replacing tools before they begin to produce out-of-spec parts, which drastically reduces material waste and unplanned downtime.

Intelligent Tool Path Planning

Instead of just following a pre-programmed path, AI can simulate and select an optimized tool path that minimizes heat concentration and mechanical stress on the PTFE part.

This leads to a cleaner cut, better surface finish, and reduced risk of internal stresses that could cause warping later.

Enhanced Quality Control

By integrating machine vision, an AI system can inspect the part during or immediately after the machining process. It can identify microscopic defects or deviations from the CAD model far more reliably than the human eye.

This creates an immediate feedback loop for process improvement and ensures that faulty parts are identified instantly.

Understanding the Trade-offs and Implementation Hurdles

Adopting this technology is a significant step that requires careful consideration of the associated challenges.

The Critical Need for High-Quality Data

AI models are only as good as the data they are trained on. Effective implementation requires outfitting machines with sensors and establishing robust systems for collecting and labeling machining data.

Without a clean and comprehensive dataset of both successful and failed machining runs, the AI's predictions will be unreliable.

Initial Investment and Complexity

The upfront cost of sensors, computing hardware, AI software, and system integration can be substantial.

Furthermore, it requires a team with expertise in both machining and data science to properly implement and maintain the system.

The Role of Human Expertise Is Not Eliminated

AI is a powerful tool that assists, not replaces, the skilled machinist. Human experience is still crucial for setting up the initial process, interpreting complex or novel issues, and overseeing the system's overall strategy.

Making the Right Choice for Your Goal

Adopting AI should be driven by a clear operational objective. Your specific goal will determine which aspect of the technology provides the most immediate value.

- If your primary focus is maximizing precision and holding tight tolerances: Prioritize AI systems that specialize in real-time thermal monitoring and dynamic adjustment of cutting parameters.

- If your primary focus is reducing material waste and scrap rate: Invest in machine learning for predictive tool wear and in-process quality control using machine vision.

- If your primary focus is increasing throughput and overall efficiency: Use AI to analyze historical data and optimize tool paths and cycle times for proven, repeatable jobs.

Ultimately, integrating AI elevates CNC machining from a set of commands to an intelligent, responsive manufacturing process.

Summary Table:

| AI/ML Capability | Key Benefit for PTFE Machining |

|---|---|

| Real-Time Parameter Optimization | Countacts thermal expansion for superior dimensional accuracy. |

| Predictive Tool Wear Analysis | Reduces scrap rate and unplanned downtime. |

| Intelligent Tool Path Planning | Minimizes heat and stress for a better surface finish. |

| In-Process Quality Control | Instantly identifies defects, ensuring consistent quality. |

Ready to elevate your PTFE component manufacturing?

At KINTEK, we specialize in precision CNC machining of high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you receive parts that meet the most demanding specifications.

Integrating advanced manufacturing intelligence allows us to deliver unparalleled precision and consistency. Let us help you minimize waste and maximize quality.

Contact KINTEK today to discuss your custom PTFE part requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments