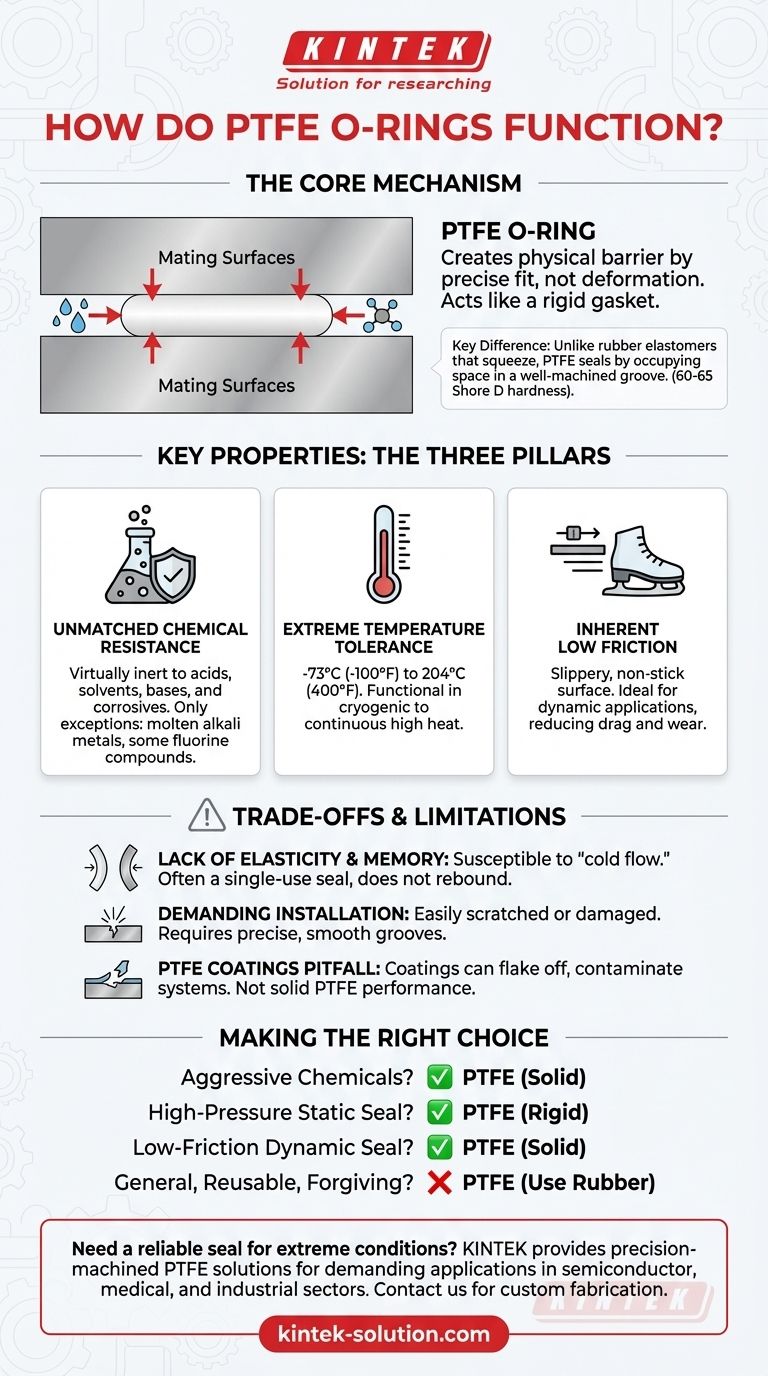

At its core, a PTFE O-ring functions by creating a physical barrier in a channel, or groove, between two mating surfaces. When the parts are assembled, the O-ring is compressed, blocking the path for liquids or gases to escape. This fundamental mechanism, combined with PTFE's unique material properties, makes it a specialized seal for demanding applications where common rubber O-rings would fail.

Unlike flexible rubber O-rings that seal by squeezing and deforming, a Polytetrafluoroethylene (PTFE) O-ring functions more like a rigid, precise gasket. Its performance hinges not on elasticity, but on its extreme chemical inertness, wide temperature range, and low-friction surface.

The Sealing Mechanism: A Tale of Two Materials

The primary job of any O-ring is to prevent leaks. However, how a hard plastic like PTFE achieves this is fundamentally different from how a soft rubber seal works.

The Universal Principle of O-Rings

All O-rings are designed to sit in a groove. When components are fastened together, the O-ring is slightly compressed, filling the gap and creating an initial seal. System pressure from the fluid or gas then pushes the O-ring more tightly against the surfaces, reinforcing the seal.

The PTFE Difference: Rigidity Over Flexibility

Standard rubber O-rings are elastomers; they are soft, flexible, and have "memory," meaning they spring back to their original shape after being compressed.

A solid PTFE O-ring is not an elastomer. It is a relatively hard plastic with a durometer of 60-65 Shore D, making it rigid and non-compressible. It does not squeeze to seal; it seals by precisely occupying the space of a well-machined groove.

Key Properties That Define PTFE's Function

The reason to select a PTFE O-ring is almost always driven by one of its three exceptional characteristics that commodity rubber cannot match.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. It is highly resistant to aggressive acids, solvents, bases, and other corrosive fluids that would quickly degrade materials like nitrile or EPDM rubber. The only notable exceptions are molten alkali metals and some fluorine compounds.

Extreme Temperature Tolerance

PTFE O-rings maintain their integrity across an exceptionally wide temperature range. They are functional in cryogenic conditions as low as -73°C (-100°F) and can withstand continuous heat up to 204°C (400°F), with some grades performing at even more extreme temperatures.

Inherent Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a slippery, non-stick surface. This makes it ideal for dynamic applications where parts must move against the seal, as it reduces drag and wear.

Understanding the Trade-offs and Limitations

The same properties that make PTFE a powerful solution also create its primary weaknesses. Understanding these trade-offs is critical to using it correctly.

Lack of Elasticity and "Memory"

Because PTFE is a rigid plastic, it does not rebound after compression like rubber. It is susceptible to "cold flow" or permanent deformation under a constant load. This means a PTFE O-ring is typically considered a single-use seal.

Demanding Installation Requirements

The hardness of PTFE makes it less forgiving than rubber. It can be scratched or damaged during installation if not handled carefully, and it cannot effectively seal surfaces with minor imperfections or irregularities. The groove it sits in must be machined to precise tolerances.

The Pitfall of PTFE Coatings

It is crucial to distinguish between a solid PTFE O-ring and a PTFE-coated O-ring. A coated ring is a standard rubber O-ring (like Viton or Silicone) with a thin PTFE film applied to the surface.

These coatings can flake off, especially in dynamic applications, contaminating the system. The coating acts only as a surface lubricant and provides no additional chemical or temperature resistance; the underlying rubber must be compatible with the environment.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material to the specific challenge of the environment.

- If your primary focus is aggressive chemical exposure: Solid PTFE is the definitive choice due to its near-universal chemical inertness.

- If your primary focus is a high-pressure static seal: PTFE's rigidity and resistance to extrusion make it a strong candidate, provided the hardware has precisely machined grooves.

- If your primary focus is a low-cost, reusable seal for general use: A standard elastomeric (rubber) O-ring is almost always the more practical and forgiving option.

- If your primary focus is reducing friction in a moving assembly: Solid PTFE is an excellent choice, but be wary of PTFE-coated rings which may only serve as a one-time installation aid.

Ultimately, choosing a PTFE O-ring means selecting a high-performance specialist designed to thrive in environments where other materials simply cannot survive.

Summary Table:

| Property | PTFE O-Ring Characteristic |

|---|---|

| Material Type | Rigid Plastic (Non-Elastomer) |

| Primary Sealing | Precise fit in a machined groove |

| Key Advantage | Extreme chemical resistance & wide temperature range |

| Temperature Range | -73°C to 204°C (-100°F to 400°F) |

| Best For | Aggressive chemicals, high heat, low-friction dynamic seals |

Need a reliable seal for extreme conditions?

PTFE O-rings from KINTEK are the definitive solution for sealing against aggressive chemicals, extreme temperatures (-100°F to 400°F), and in low-friction dynamic applications. Unlike standard rubber, our precision-machined PTFE components (including seals, liners, and labware) provide unmatched performance where other materials fail.

We specialize in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors, from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific sealing challenge and get a quote for a high-performance PTFE solution.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the common plumbing applications of PTFE? Ensure Leak-Proof, Durable Seals

- Why is PTFE widely used in the automotive industry? Solve Heat, Friction, and Chemical Challenges

- What are O-rings and their primary function? The Key to Leak-Free Sealing in Any System

- Are the specifications of PTFE bushings customizable? Get a Tailored Solution for Your Application

- Why are PTFE O-Rings considered versatile for low-pressure, static applications? Unlock Superior Chemical and Thermal Resistance

- What are the benefits of using a PTFE coating thrust washer in a fishing reel? Smoother Drag, Longer Reel Life

- What unique feature does the PTFE oil seal have for fluid retention? Active Hydrodynamic Sealing Explained

- What are the applications of Teflon bearings in extreme environments? Ensure Reliability from -400°F to +550°F