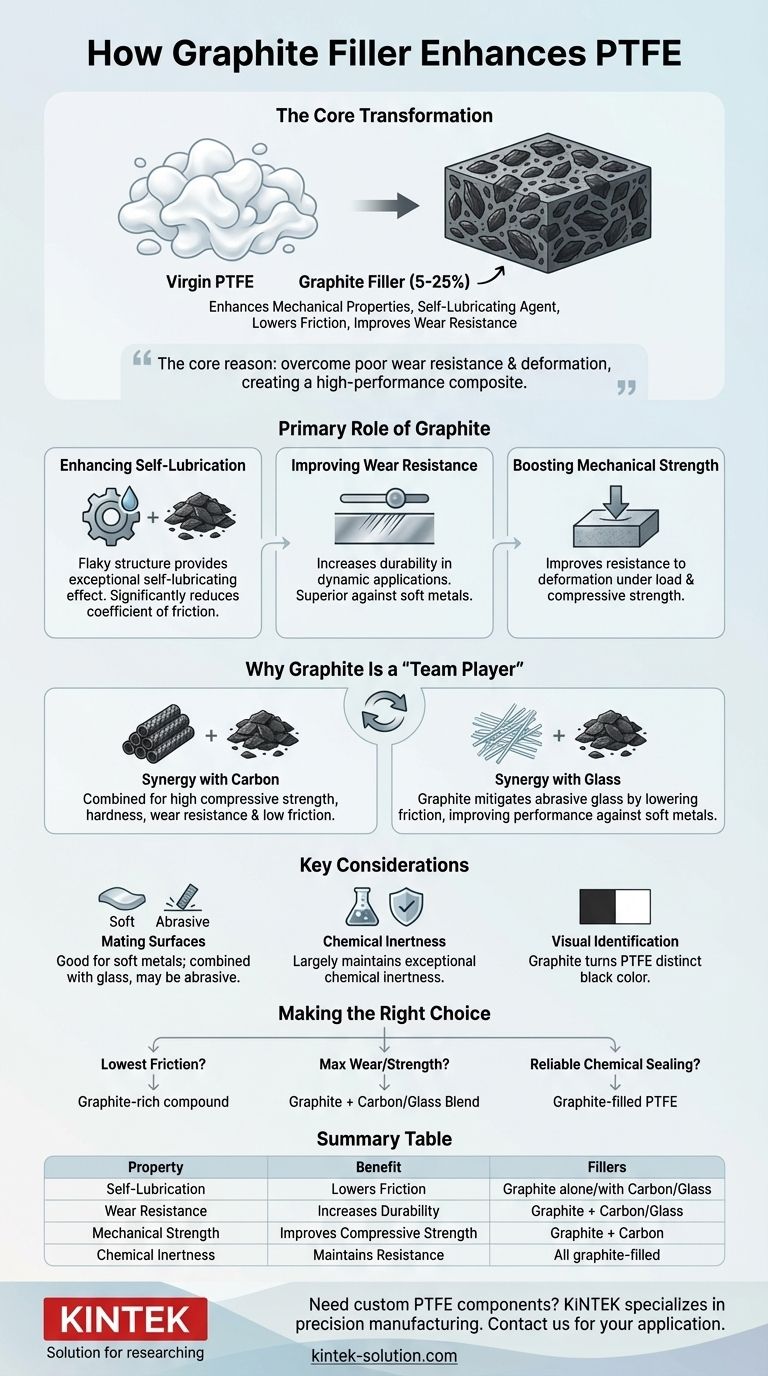

To enhance its mechanical properties, graphite is used as a filler in Polytetrafluoroethylene (PTFE), typically in concentrations between 5% and 25%. It acts as a self-lubricating agent that dramatically lowers the coefficient of friction and improves wear resistance. Critically, graphite is often not used alone; it is frequently combined with other fillers like carbon or glass to create a composite material with a superior balance of characteristics.

The core reason for adding graphite to PTFE is to overcome the base polymer's poor wear resistance and tendency to deform under load. By introducing graphite, you create a high-performance composite that retains PTFE's chemical inertness while gaining crucial strength and self-lubricating properties for demanding dynamic applications.

The Primary Role of Graphite in PTFE

Adding graphite filler fundamentally changes PTFE from a soft, pliable polymer into a robust engineering material. This transformation is driven by several key property enhancements.

Enhancing Self-Lubrication

Graphite’s unique, flaky particle structure provides an exceptional self-lubricating effect within the PTFE matrix.

This inherent lubricity significantly reduces the material's coefficient of friction, even beyond the already low friction of virgin PTFE.

Improving Wear Resistance

The addition of graphite makes the resulting compound far more durable in dynamic applications.

It significantly improves wear resistance, especially in sliding applications against soft metal surfaces where unfilled PTFE would fail quickly.

Boosting Mechanical Strength

Graphite-filled PTFE exhibits better mechanical properties than the virgin polymer.

It improves the material's resistance to deformation under load and enhances its overall compressive strength, making it more suitable for seals and bearings.

Why Graphite Is a "Team Player"

While graphite provides significant benefits on its own, its true value is often realized when combined with other fillers. This creates a synergistic effect, where the final compound is superior to one with a single filler.

Synergy with Carbon

Carbon fiber is often added to PTFE to increase compressive strength, hardness, and wear resistance.

When graphite is added to a carbon-PTFE blend, it lowers the coefficient offriction, resulting in a composite that is strong, durable, and has excellent sliding properties.

Synergy with Glass

Glass fiber is a common filler used to drastically increase wear resistance and compressive strength.

However, glass can be abrasive to softer mating surfaces. Adding graphite to a glass-PTFE blend mitigates this by lowering friction and improving the material's performance against softer metals.

Understanding the Trade-offs

While graphite-filled PTFE is a high-performance material, it's essential to understand its characteristics in context.

Impact on Mating Surfaces

Graphite itself is an excellent choice for applications involving soft metals like aluminum or stainless steel.

However, when combined with more abrasive fillers like glass, the overall compound may be less suitable for those same soft surfaces. The complete formulation must be considered.

Chemical Inertness

A primary advantage of this compound is that it largely maintains the exceptional chemical inertness of virgin PTFE.

This makes it a superior choice for sealing applications in chemically aggressive environments where elastomers would fail.

Visual Identification

The addition of graphite turns the material a distinct black color.

This provides an easy visual cue to distinguish it from virgin PTFE, which is characteristically white.

Making the Right Choice for Your Application

Selecting the correct material composition is critical to achieving your performance goals.

- If your primary focus is the lowest possible friction: A PTFE compound with a higher percentage of graphite is ideal, especially for dynamic seals or bearings operating against soft metals.

- If your primary focus is maximum wear resistance and strength: A blend of graphite with carbon or glass fiber will provide the necessary durability for high-load or abrasive environments.

- If your primary focus is reliable chemical sealing: Graphite-filled PTFE offers a superior sealing solution due to its low friction, chemical inertness, and improved resistance to deformation.

By understanding how graphite modifies PTFE, you can select a material precisely engineered for your specific mechanical and chemical demands.

Summary Table:

| Property Enhancement | Key Benefit | Typical Filler Combinations |

|---|---|---|

| Self-Lubrication | Lowers coefficient of friction | Graphite alone, or with Carbon/Glass |

| Wear Resistance | Increases durability in dynamic applications | Graphite + Carbon, Graphite + Glass |

| Mechanical Strength | Improves compressive strength & load resistance | Graphite + Carbon |

| Chemical Inertness | Maintains PTFE's resistance to aggressive chemicals | All graphite-filled compounds |

Need a custom PTFE component with enhanced performance?

At KINTEK, we specialize in manufacturing precision PTFE components, including graphite-filled composites for superior wear resistance and self-lubrication. Our expertise is ideal for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact mechanical and chemical requirements.

Contact us today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs