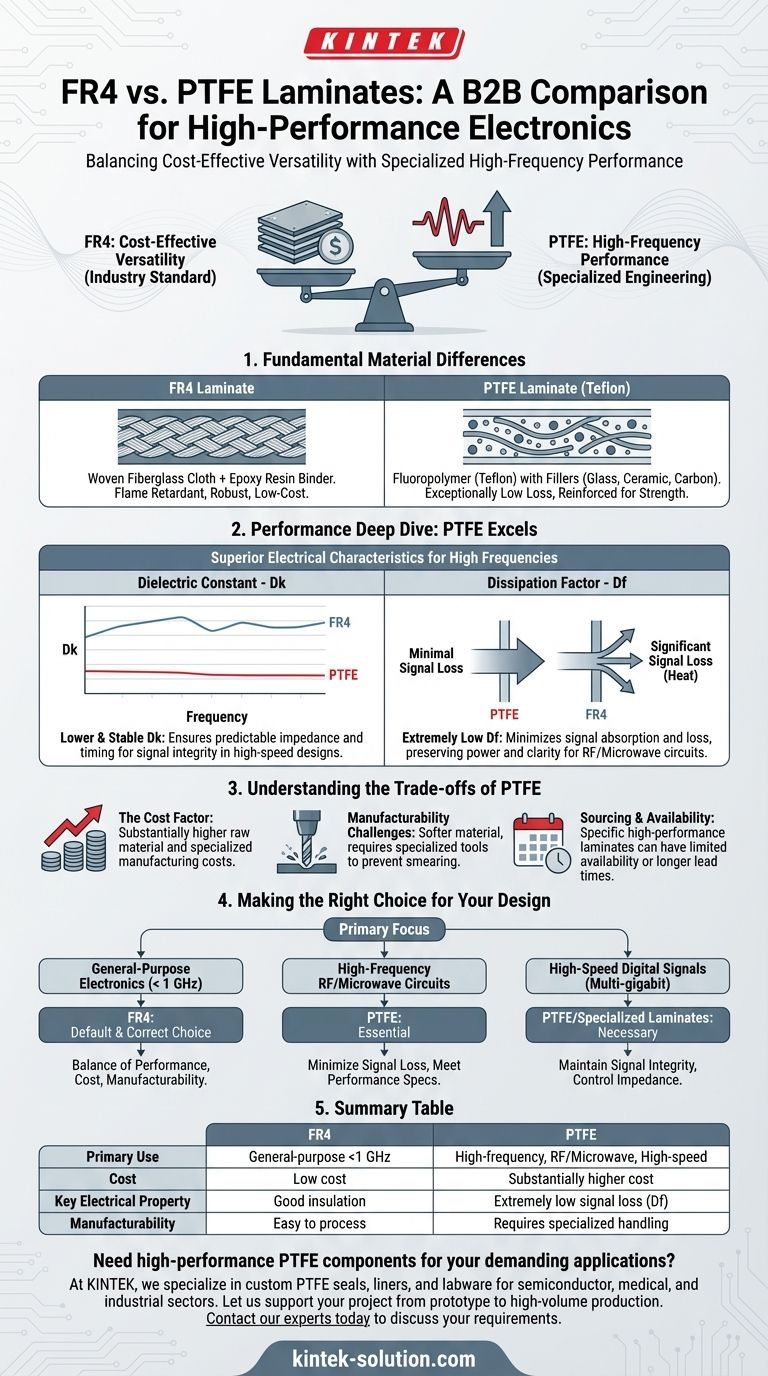

At its core, the choice between FR4 and PTFE laminates is a fundamental trade-off between cost-effective versatility and specialized high-frequency performance. FR4 is the ubiquitous, affordable industry standard suitable for the vast majority of electronic applications. PTFE is a premium material engineered specifically for high-speed and high-frequency circuits where minimizing signal loss is paramount.

The decision to use PTFE over FR4 is almost exclusively driven by the operating frequency of your circuit. If your design involves high-speed digital signals or RF/microwave energy, the superior electrical properties of PTFE become a necessity, justifying its higher cost and manufacturing complexity.

The Fundamental Material Differences

To understand when to use each material, you must first understand what they are and why their inherent properties differ so drastically.

FR4: The Industry Workhorse

FR4 is a composite material made of woven fiberglass cloth with an epoxy resin binder. It is flame retardant (the "FR" in its name) and provides a robust, low-cost structure with good electrical insulation for most applications.

Its wide adoption means it is readily available from countless suppliers and every PCB fabricator is equipped to process it efficiently. This makes it the default choice for prototyping and mass production of consumer electronics, industrial controls, and automotive systems.

PTFE: The High-Frequency Specialist

PTFE, widely known by the brand name Teflon, is a fluoropolymer with exceptionally low electrical loss. On its own, it is too soft for most PCB applications, so it is typically reinforced with fillers.

These fillers, such as glass, ceramic, or carbon, are not just for structure. They are critical for enhancing PTFE's mechanical strength, improving thermal conductivity, and providing the dimensional stability required for reliable circuit manufacturing.

Performance Deep Dive: Where PTFE Excels

The higher cost of PTFE is a direct payment for its superior electrical characteristics, which become non-negotiable as signal frequencies increase.

Dielectric Constant (Dk)

PTFE laminates have a lower and significantly more stable dielectric constant across a wide range of frequencies. This stability is crucial for high-speed designs, as it ensures predictable impedance and timing, which are core to maintaining signal integrity.

Dissipation Factor (Df)

This is arguably the most important differentiator. PTFE has an extremely low dissipation factor, or loss tangent. This means very little signal energy is absorbed and lost as heat within the material. For RF and microwave circuits, a low Df is essential for preserving the power and clarity of the signal.

Understanding the Trade-offs

Choosing PTFE is not just a performance upgrade; it introduces a new set of design and manufacturing considerations.

The Cost Factor

There is no ambiguity here: PTFE is substantially more expensive than FR4. The raw material cost is higher, and the specialized handling required during manufacturing further increases the price of the final board.

Manufacturability Challenges

PTFE is a softer material than FR4. This softness can lead to issues like smearing during drilling, which requires specialized tools and techniques to prevent. This processing difficulty is a primary contributor to its higher fabrication cost.

Sourcing and Availability

While FR4 is a commodity, specific high-performance PTFE laminates can have limited availability or longer lead times. This makes early collaboration with your PCB fabricator essential to ensure the material you specify is available and that they have the capability to process it correctly.

Making the Right Choice for Your Design

Your application's operating frequency and budget are the primary drivers for this material decision.

- If your primary focus is cost-effective, general-purpose electronics (below 1 GHz): FR4 is the default and correct choice for its balance of performance, cost, and manufacturability.

- If your primary focus is high-frequency RF or microwave circuits: PTFE is essential to minimize signal loss and ensure your design meets its performance specifications.

- If your primary focus is high-speed digital signals (multi-gigabit): PTFE or other specialized high-performance laminates are necessary to maintain signal integrity and control impedance.

Ultimately, selecting the right laminate is a foundational engineering decision that directly impacts both the performance and the final cost of your product.

Summary Table:

| Feature | FR4 Laminate | PTFE Laminate |

|---|---|---|

| Primary Use | General-purpose electronics (<1 GHz) | High-frequency, RF/Microwave, High-speed digital |

| Cost | Low cost, industry standard | Substantially higher cost |

| Key Electrical Property | Good insulation for most applications | Extremely low signal loss (Dissipation Factor) |

| Manufacturability | Easy to process, widely available | Requires specialized handling and tools |

Need high-performance PTFE components for your demanding applications?

At KINTEK, we specialize in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, and industrial sectors. Our expertise in advanced materials like PTFE ensures your designs meet the highest standards for performance and reliability.

Let us support your project from prototype to high-volume production. Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support