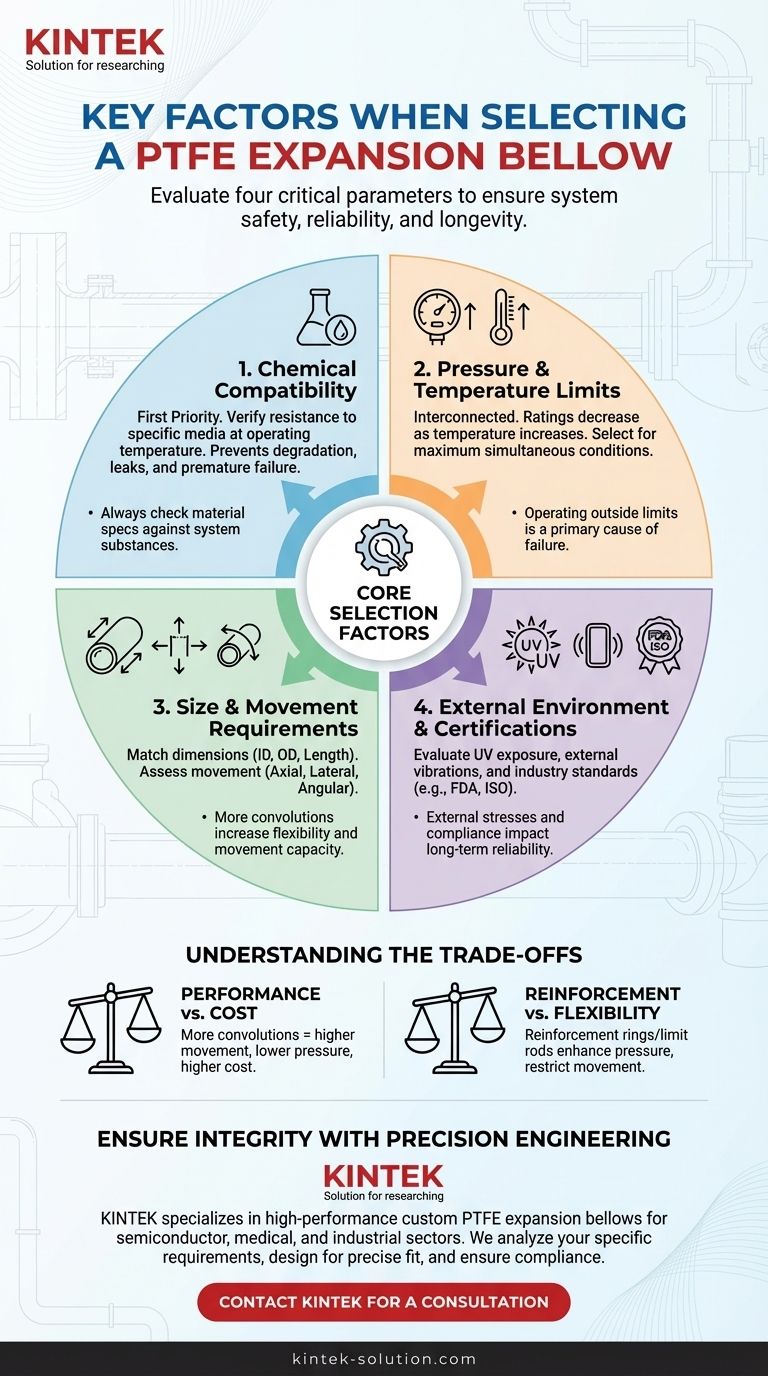

To select the right PTFE expansion bellow, you must evaluate four critical factors: the chemical compatibility with your system's media, the operational pressure and temperature ratings, the required physical size and movement capabilities, and the external installation environment. These parameters dictate the bellow's ability to perform safely and reliably over its service life.

The core task is not just finding a bellow that fits, but one that is precisely engineered for your system's specific chemical, thermal, and mechanical stresses. A mismatch in any single factor can compromise the integrity of your entire system, leading to failure, downtime, and safety risks.

Why Precise Selection is Non-Negotiable

Choosing an expansion bellow can seem straightforward, but it is a critical engineering decision. The correct component ensures system efficiency, enhances safety, and significantly reduces long-term maintenance costs.

An expansion bellow is designed to absorb movement and vibration between pipe sections. In environments with aggressive chemicals or extreme temperatures, a failure is not just an inconvenience; it can be a catastrophic event. Proper selection is your primary defense against such risks.

Core Technical Specifications

Every selection process must begin with a clear understanding of the system's fundamental operating parameters. These non-negotiable details form the foundation of your decision.

Chemical Compatibility

This is the first and most important consideration. PTFE is known for its exceptional chemical resistance, but you must confirm its compatibility with the specific media flowing through your system, especially at operating temperatures.

An incompatible material can degrade, leading to leaks and premature failure. Always verify the bellow's material specifications against your system's substances.

Pressure and Temperature Limits

Pressure and temperature are interconnected. A bellow's maximum pressure rating often decreases as the temperature increases.

You must select a bellow rated to handle the maximum potential pressure and temperature of your system simultaneously. Operating outside these specified limits is a primary cause of bellow failure.

Size and Movement Requirements

The bellow must physically fit your piping and absorb the necessary movement. Key dimensions include the internal diameter (ID), external diameter (OD), and overall length.

Equally important is the type and magnitude of movement it needs to absorb, which can include axial (compression/extension), lateral (sideways), or angular motion. The number of convolutions in the bellow directly impacts its flexibility and movement capacity.

Assessing the Operational Environment

A bellow does not exist in a vacuum. The external conditions are just as important as the internal ones for ensuring long-term reliability.

External Conditions

Consider the environment where the bellow will be installed. Will it be exposed to direct sunlight (UV radiation), which can degrade certain materials over time? Is the system subject to significant external vibrations?

These factors can impose additional stress on the component and may require specific design features or materials for durability.

Industry-Specific Certifications

For industries like pharmaceuticals, food and beverage, or electronics, material purity and compliance are critical.

Ensure the PTFE expansion bellow meets necessary standards, such as FDA for food contact or other ISO certifications relevant to your application. This guarantees the material is safe and appropriate for its intended use.

Understanding the Trade-offs

Selecting the ideal bellow often involves balancing competing factors. Understanding these trade-offs is key to making an informed decision.

Performance vs. Cost

A bellow with more convolutions will typically offer greater movement capability but may have a lower pressure rating and a higher cost. You must balance the required flexibility with the system's pressure demands and your project budget.

Reinforcement vs. Flexibility

Features like reinforcement rings or limit rods enhance a bellow's pressure rating and prevent over-extension, adding a layer of safety. However, these features can restrict the bellow's natural movement. The choice depends on whether the primary need is maximum flexibility or robust pressure containment.

Making the Right Choice for Your System

With a clear understanding of these factors, you can align your selection with your primary operational goal. Always consult with a knowledgeable supplier to validate your choice against your specific application's demands.

- If your primary focus is high-purity applications: Prioritize material purity and ensure the bellow holds the necessary certifications, such as FDA compliance.

- If your primary focus is aggressive chemical processing: Double-check the chemical compatibility at your maximum operating temperature and pressure.

- If your primary focus is managing high vibration or pipe misalignment: Select a bellow specifically designed with the number of convolutions needed to absorb the required axial and lateral movement.

Ultimately, a well-chosen PTFE expansion bellow is a critical investment in your system's long-term safety and reliability.

Summary Table:

| Selection Factor | Key Consideration | Why It Matters |

|---|---|---|

| Chemical Compatibility | Verify PTFE resistance to specific media at operating temperature. | Prevents degradation, leaks, and premature failure. |

| Pressure & Temperature | Confirm ratings for your system's maximum simultaneous conditions. | Operating outside limits is a primary cause of failure. |

| Size & Movement | Match internal/external diameter and length; assess axial/lateral/angular motion needs. | Ensures proper fit and ability to absorb system movement. |

| External Environment | Evaluate UV exposure, external vibrations, and required industry certifications (FDA, ISO). | External stresses and compliance needs impact long-term reliability. |

Ensure Your System's Integrity with Precision-Engineered PTFE Bellows

Selecting the right expansion bellow is critical to the safety, efficiency, and longevity of your system. At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom expansion bellows, for the semiconductor, medical, laboratory, and industrial sectors.

We understand that a one-size-fits-all approach doesn't work. Our experts will work with you to:

- Analyze your specific chemical, pressure, and temperature requirements.

- Design and fabricate a bellow that precisely matches your size, movement, and environmental needs.

- Ensure compliance with industry-specific certifications for purity and safety.

Don't leave your system's reliability to chance. Partner with a supplier committed to precision production from prototypes to high-volume orders.

Contact KINTEK today for a consultation and let us engineer the perfect PTFE expansion bellow solution for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability