Selecting the right PTFE packing is a critical decision that directly impacts equipment performance, operational safety, and the longevity of your machinery. An incorrect choice is not a minor issue; it can lead to premature seal failure, costly downtime, and potentially hazardous leaks. A well-matched packing, however, ensures a reliable and efficient seal under demanding conditions.

The core challenge is not simply choosing PTFE, but choosing the specific PTFE packing solution engineered for your system's unique chemical, thermal, and mechanical demands. A mismatch introduces a deliberate point of failure, compromising the integrity of your entire operation.

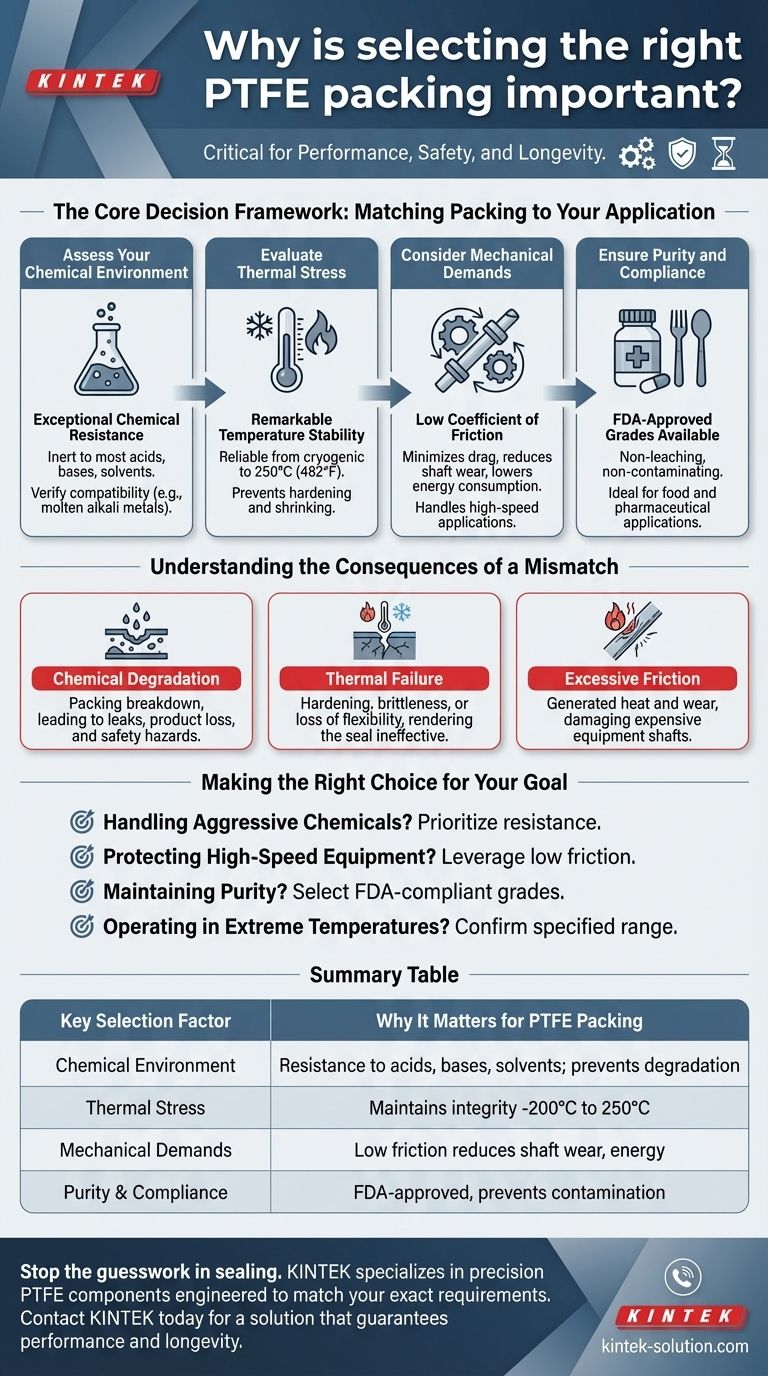

The Core Decision Framework: Matching Packing to Your Application

To make the right choice, you must evaluate your operational environment against the key properties of PTFE packing. This systematic approach ensures the packing you select is an asset, not a liability.

Assess Your Chemical Environment

PTFE is renowned for its exceptional chemical resistance. It is a nearly inert material, meaning it does not react with most chemicals, including aggressive acids, bases, and solvents.

This makes it an ideal choice for systems handling substances like concentrated sulfuric or nitric acid. However, you must always verify compatibility, as a few substances (like molten alkali metals) can degrade it.

Evaluate Thermal Stress

PTFE packing offers remarkable temperature stability. It performs reliably across a vast range, from cryogenic temperatures up to 250°C (482°F).

This stability is crucial for preventing the packing from hardening, shrinking, or degrading when exposed to extreme operational temperatures, ensuring a consistent and reliable seal.

Consider Mechanical Demands

Your equipment's pressure and shaft speed are critical mechanical factors. PTFE's extremely low coefficient of friction is one of its most significant advantages.

This low-friction characteristic minimizes drag on rotating shafts, which reduces equipment wear and lowers energy consumption. It also allows the packing to better withstand the mechanical stress of high-speed applications.

Ensure Purity and Compliance

In sensitive industries, the packing material itself cannot become a contaminant. PTFE packing does not bleed color or leach materials into the process media.

Because of this purity, specific grades of PTFE packing are FDA-approved, making them a standard and safe choice for food production and pharmaceutical applications where product integrity is paramount.

Understanding the Consequences of a Mismatch

Choosing a packing without careful consideration of the operating environment leads to predictable and preventable failures. Understanding these risks highlights the importance of a correct initial selection.

The Risk of Chemical Degradation

If the packing is not fully compatible with the process media, it will chemically break down. This degradation destroys its sealing ability, leading directly to leaks.

Leaks can result in lost product, damage to surrounding equipment, and significant safety hazards for personnel.

The Impact of Thermal Failure

Using a packing outside of its specified temperature range will cause it to fail. At high temperatures, it can harden and become brittle; at extreme lows, it may lose its flexibility.

In either case, the packing loses its ability to conform to the shaft and stuffing box, rendering the seal ineffective.

The Cost of Excessive Friction

A packing not suited for the shaft speed or pressure will generate excess heat and wear. This not only accelerates the degradation of the packing itself but, more importantly, can score and damage the equipment shaft.

Repairing or replacing a damaged shaft is a far more complex and expensive undertaking than simply replacing the packing.

Making the Right Choice for Your Goal

Your primary operational goal should guide your final selection. Use these points to prioritize what matters most for your application.

- If your primary focus is handling aggressive chemicals: Prioritize verifying the packing's resistance to your specific media, as PTFE's inertness is its greatest asset here.

- If your primary focus is protecting high-speed rotating equipment: Choose a packing that leverages PTFE's low coefficient of friction to minimize shaft wear and reduce energy consumption.

- If your primary focus is maintaining purity in food or pharmaceutical applications: Select an FDA-compliant PTFE packing that will not leach or contaminate the process media.

- If your primary focus is operating in extreme temperatures: Confirm the packing’s specified range, from cryogenic lows to high heat, to ensure a stable and reliable seal.

Ultimately, a well-chosen PTFE packing becomes an invisible but essential component of a reliable and efficient system.

Summary Table:

| Key Selection Factor | Why It Matters for PTFE Packing |

|---|---|

| Chemical Environment | Ensures resistance to aggressive acids, bases, and solvents, preventing degradation and leaks. |

| Thermal Stress | Maintains seal integrity across a wide temperature range (-200°C to 250°C / -328°F to 482°F). |

| Mechanical Demands | Low friction reduces shaft wear and energy consumption in high-speed applications. |

| Purity & Compliance | FDA-approved grades prevent contamination in food, pharmaceutical, and sensitive processes. |

Stop the guesswork in sealing.

For semiconductor, medical, laboratory, and industrial applications, the wrong PTFE packing is a deliberate point of failure. KINTEK specializes in precision PTFE components—from custom seals and liners to labware—engineered to match your exact chemical, thermal, and mechanical requirements.

We provide custom fabrication from prototypes to high-volume orders, ensuring your equipment operates safely and efficiently.

Contact KINTEK today for a solution that guarantees performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the benefits of using Teflon bellow mechanical seals in high-temperature applications? Superior Sealing for Harsh Chemicals

- What are the benefits of porous PTFE? Unlock Superior Filtration and Chemical Resistance

- How are PTFE lined butterfly valves installed? Achieve a Perfect, Leak-Free Seal

- What are the benefits of using PTFE for seals and gaskets? Unlock Superior Chemical & Thermal Resistance

- Why are PTFE bearing pads essential? Ensure Structural Safety and Longevity with Low-Friction Solutions

- What are the key benefits of using PTFE gaskets? Achieve Unmatched Chemical & Temperature Resistance

- What are the key properties of ePTFE? Unlock Superior Sealing, Filtration & Medical Solutions

- What are the differences between Teflon and rubber sealed bearings? Choose the Right Seal for Speed or Protection