The primary benefits of using PTFE for seals and gaskets are its nearly universal chemical resistance, its exceptional stability across a wide temperature range, and its extremely low coefficient of friction. This unique combination makes it a default material choice for the most demanding industrial applications, from chemical processing to aerospace engineering.

Polytetrafluoroethylene (PTFE) is a high-performance polymer prized for its resilience in extreme environments. While its chemical and thermal properties are unmatched, a successful application depends on understanding its key mechanical limitation: its tendency to deform, or "creep," under sustained pressure.

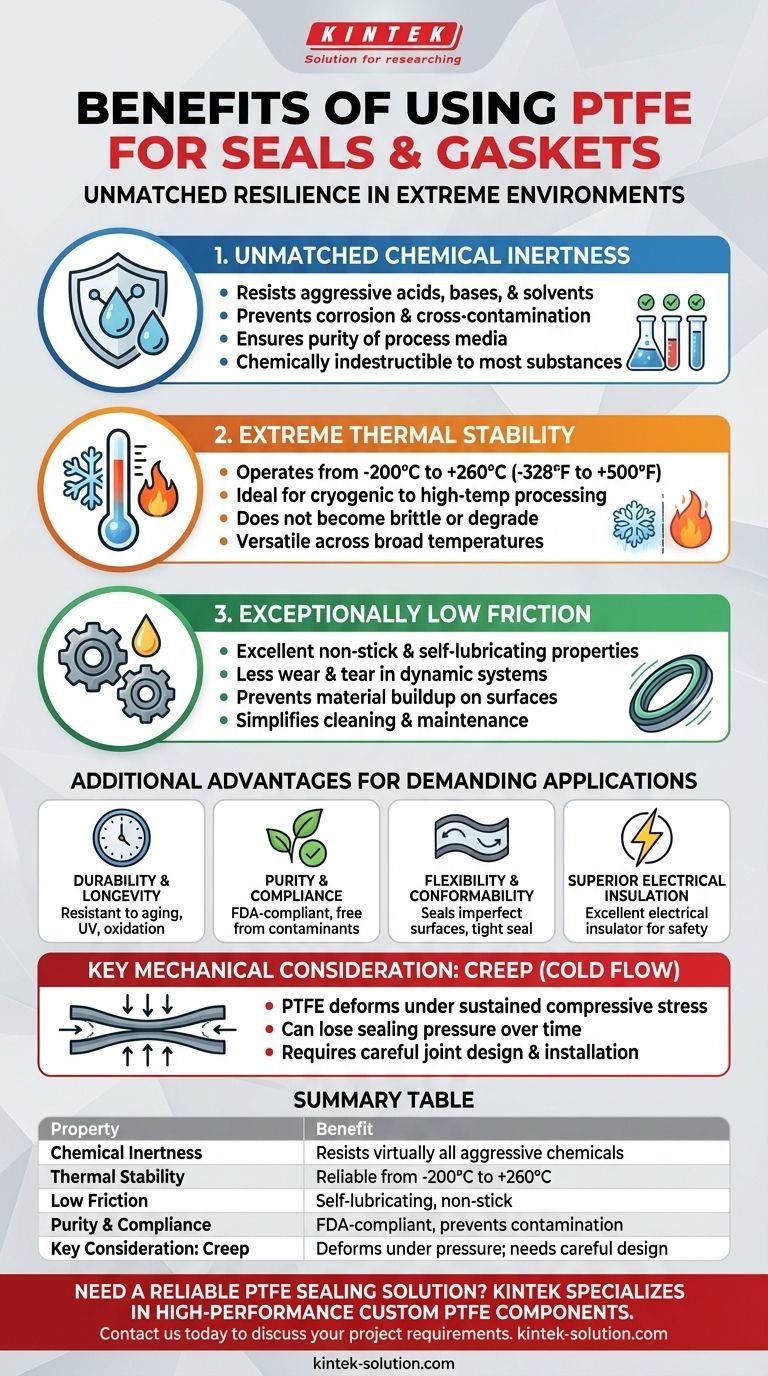

The Core Strengths of PTFE in Sealing Applications

To understand why PTFE is so widely used, we must examine its three foundational properties. These characteristics allow it to perform where many other materials would fail catastrophically.

Unmatched Chemical Inertness

PTFE is famous for being chemically indestructible to most substances. It provides a reliable seal when exposed to aggressive acids, bases, solvents, and other harsh chemicals that would quickly degrade lesser materials.

This property prevents corrosion and cross-contamination, ensuring the purity of the process media and the longevity of the seal itself.

Extreme Thermal Stability

PTFE seals and gaskets operate effectively across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in everything from cryogenic applications to high-temperature processing without becoming brittle or degrading, a versatility few other polymers can offer.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it excellent non-stick and self-lubricating properties.

For sealing applications, this means less wear and tear in dynamic or rotating systems. It also prevents material buildup on the gasket surface, simplifying cleaning and maintenance.

Why PTFE Excels in Demanding Environments

Beyond its core strengths, PTFE offers several other advantages that make it a durable and versatile sealing solution.

Durability and Longevity

PTFE is highly resistant to environmental factors. It does not age or corrode from exposure to the elements and is resistant to both oxidation and UV radiation. This inherent durability translates to a long service life and reduced maintenance needs.

Purity and Compliance

Due to its inert nature, PTFE is free from contaminants that could leach into a system. This makes it a material of choice for sensitive applications in the food, beverage, and pharmaceutical industries, with many grades being FDA-compliant.

Flexibility and Conformability

PTFE gaskets are flexible, allowing them to create a tight seal even on uneven or imperfect flange surfaces. This conformability ensures superior sealing performance against both gas and liquid leakage under repeated compression cycles.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, a property that is valuable in applications where electrical isolation is a critical safety or operational requirement.

Understanding the Primary Trade-off: Creep

No material is perfect, and PTFE's primary drawback is mechanical, not chemical or thermal. Trustworthy engineering requires acknowledging this limitation.

What is Creep?

The most significant disadvantage of pure PTFE is its tendency to creep (also known as cold flow). This is the material's tendency to slowly and permanently deform when subjected to a sustained compressive stress, like the force from a bolted flange.

The Impact on Sealing Integrity

Creep can cause a seal to lose its initial compressive load over time. This reduction in sealing pressure can eventually lead to leaks, especially in applications with high pressure or significant temperature fluctuations. Careful design and proper installation procedures are essential to manage this effect.

Making the Right Choice for Your Application

Selecting the right sealing material requires balancing performance needs with material properties.

- If your primary focus is aggressive chemical media: PTFE is an almost unparalleled choice due to its nearly universal chemical inertness.

- If your application involves extreme hot or cold temperatures: PTFE's stability from cryogenic levels to over 250°C makes it a highly reliable option.

- If you require a low-friction or non-stick surface: PTFE is ideal for dynamic seals or applications where preventing material buildup is critical.

- If your assembly involves high, sustained bolt loads: You must carefully design the joint to account for PTFE's tendency to creep, which could compromise the seal's integrity over time.

By understanding both its exceptional strengths and its key limitation, you can effectively leverage PTFE to create a reliable and long-lasting seal in the most challenging environments.

Summary Table:

| Property | Benefit for Seals & Gaskets |

|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents. |

| Thermal Stability | Performs reliably from -200°C to +260°C. |

| Low Coefficient of Friction | Self-lubricating; ideal for dynamic seals and non-stick surfaces. |

| Purity & Compliance | FDA-compliant; prevents contamination in food, pharma, and lab settings. |

| Key Consideration: Creep | Can deform under sustained pressure; requires careful joint design. |

Need a reliable PTFE sealing solution for your demanding application?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between PTFE's unmatched chemical/thermal resistance and its mechanical behavior, ensuring your seals perform reliably.

Whether you need a prototype or high-volume production, our expertise in custom fabrication delivers the exact solution you need.

Contact us today to discuss your project requirements and let our experts help you achieve a leak-free, long-lasting seal.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry