The fundamental difference between Teflon and rubber-sealed bearings is a direct trade-off between speed and protection. Teflon seals create less friction, allowing for higher rotational speeds, while rubber seals provide a more robust barrier against environmental contaminants like dust and water.

Your choice is not about which seal material is inherently superior, but about which one is correctly aligned with your specific application. Teflon prioritizes low-friction performance, whereas rubber prioritizes maximum protection and operational longevity in harsh conditions.

The Core Function of a Bearing Seal

A bearing seal serves two critical purposes. First, it must keep the internal lubricant—grease or oil—inside the bearing assembly. Second, it must prevent external contaminants like dirt, dust, and moisture from getting in and damaging the highly polished internal surfaces.

The material and design of this seal dictate how well it performs these two jobs, directly creating the central trade-off between the two types.

Analyzing Teflon Seals

Teflon-sealed bearings are engineered primarily for performance where minimal friction is the highest priority. They are often referred to as low-contact or non-contact seals.

The Advantage: Minimal Rolling Resistance

Because the Teflon shield barely touches (or doesn't touch at all) the bearing's inner race, it generates significantly less drag. This translates directly to higher efficiency and speed, making it ideal for high-performance applications in controlled environments.

The Weakness: Weaker Environmental Barrier

This same low-contact design that reduces friction also creates a less effective barrier. It can allow fine dust particles and moisture to penetrate the bearing over time, especially in dirty or wet conditions.

Analyzing Rubber Seals

Rubber-sealed bearings are the standard for reliability in a vast range of industrial and consumer applications. They are designed as full-contact seals.

The Advantage: Superior Protection

The flexible rubber lip presses firmly against the bearing's inner race, creating a highly effective barrier. This robust seal is excellent at keeping contaminants out and lubricant in, making it the default choice for equipment that operates outdoors or in dirty environments.

The Weakness: Increased Friction

The constant contact between the rubber lip and the inner race generates more friction and drag than a Teflon seal. While often negligible in many applications, this can be a limiting factor where maximum rotational speed or efficiency is critical.

Understanding the Trade-offs

The decision between Teflon and rubber is not about quality but about matching the bearing's design to its intended use case. Misunderstanding this can lead to premature failure.

Speed vs. Longevity

A Teflon-sealed bearing will allow a wheel or shaft to spin more freely. However, if used in a mountain bike hub, for instance, it would likely fail much faster than a rubber-sealed equivalent due to contamination from mud and water.

Clean vs. Dirty Environments

The single most important factor in your decision is the operating environment. For machinery used indoors in a clean workshop or for competitive racing on a dry, clean track, Teflon offers a distinct performance advantage. For all-weather commuting, agricultural equipment, or construction machinery, rubber's protective qualities are non-negotiable.

Defining "Durability"

While the Teflon material itself is highly durable, the durability of the bearing assembly is compromised in dirty conditions due to its weaker seal. Conversely, a rubber-sealed bearing provides greater assembly durability in harsh environments, even if the seal itself eventually wears from friction.

Making the Right Choice for Your Application

To make the correct decision, you must prioritize your primary goal.

- If your primary focus is maximum speed and efficiency in a clean, controlled environment: Choose Teflon-sealed bearings for their significantly lower rolling resistance.

- If your primary focus is reliability and longevity in dirty, wet, or unpredictable conditions: Choose rubber-sealed bearings for their superior protection against contaminants.

By matching the seal type to your operating environment, you ensure the best possible balance of performance and longevity for your equipment.

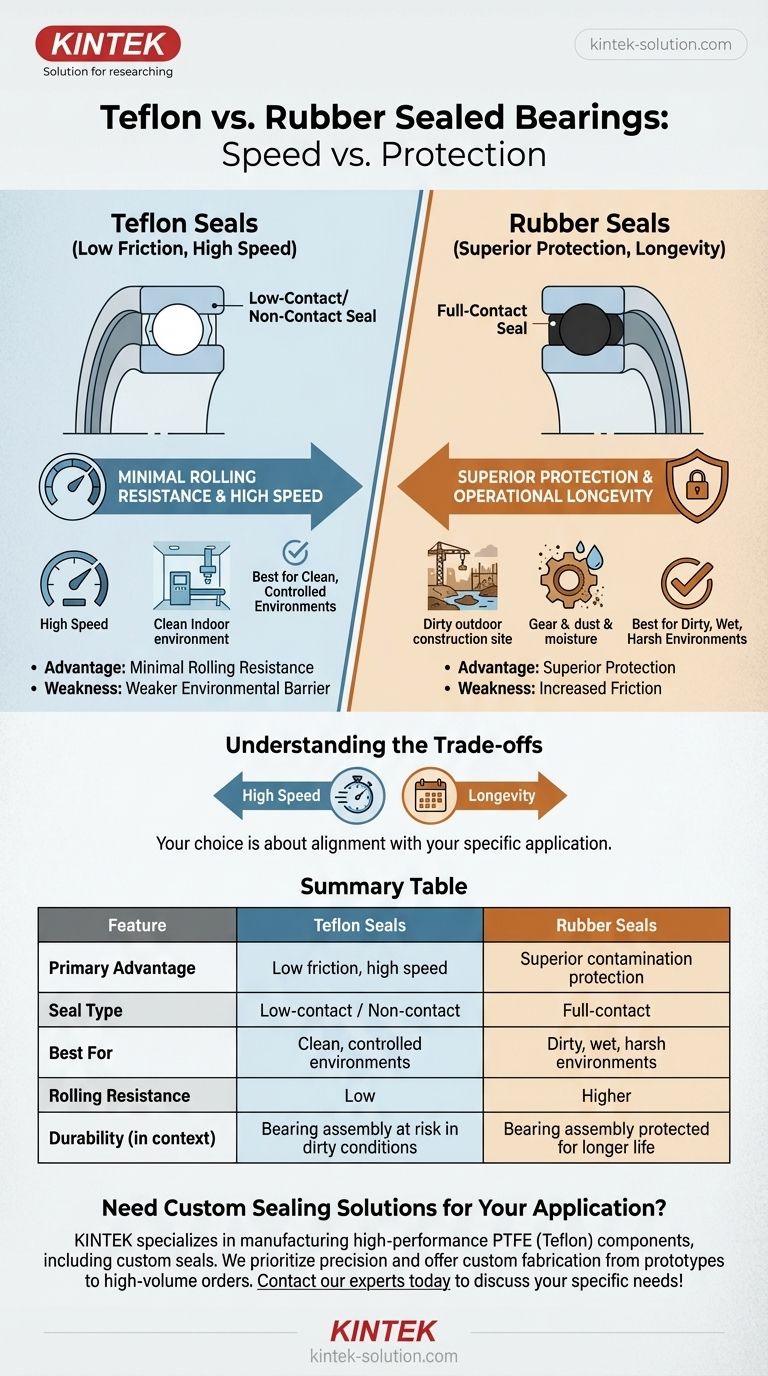

Summary Table:

| Feature | Teflon Seals | Rubber Seals |

|---|---|---|

| Primary Advantage | Low friction, high speed | Superior contamination protection |

| Seal Type | Low-contact / Non-contact | Full-contact |

| Best For | Clean, controlled environments | Dirty, wet, harsh environments |

| Rolling Resistance | Low | Higher |

| Durability (in context) | Bearing assembly at risk in dirty conditions | Bearing assembly protected for longer life |

Need Custom Sealing Solutions for Your Application?

Choosing the right seal is critical for performance and longevity. At KINTEK, we specialize in manufacturing high-performance PTFE (Teflon) components, including custom seals, liners, and labware.

Whether you require the low-friction properties of PTFE for high-speed applications or a custom solution for a specialized industrial, semiconductor, medical, or laboratory environment, we can help. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Let us help you optimize your equipment's performance and reliability. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal