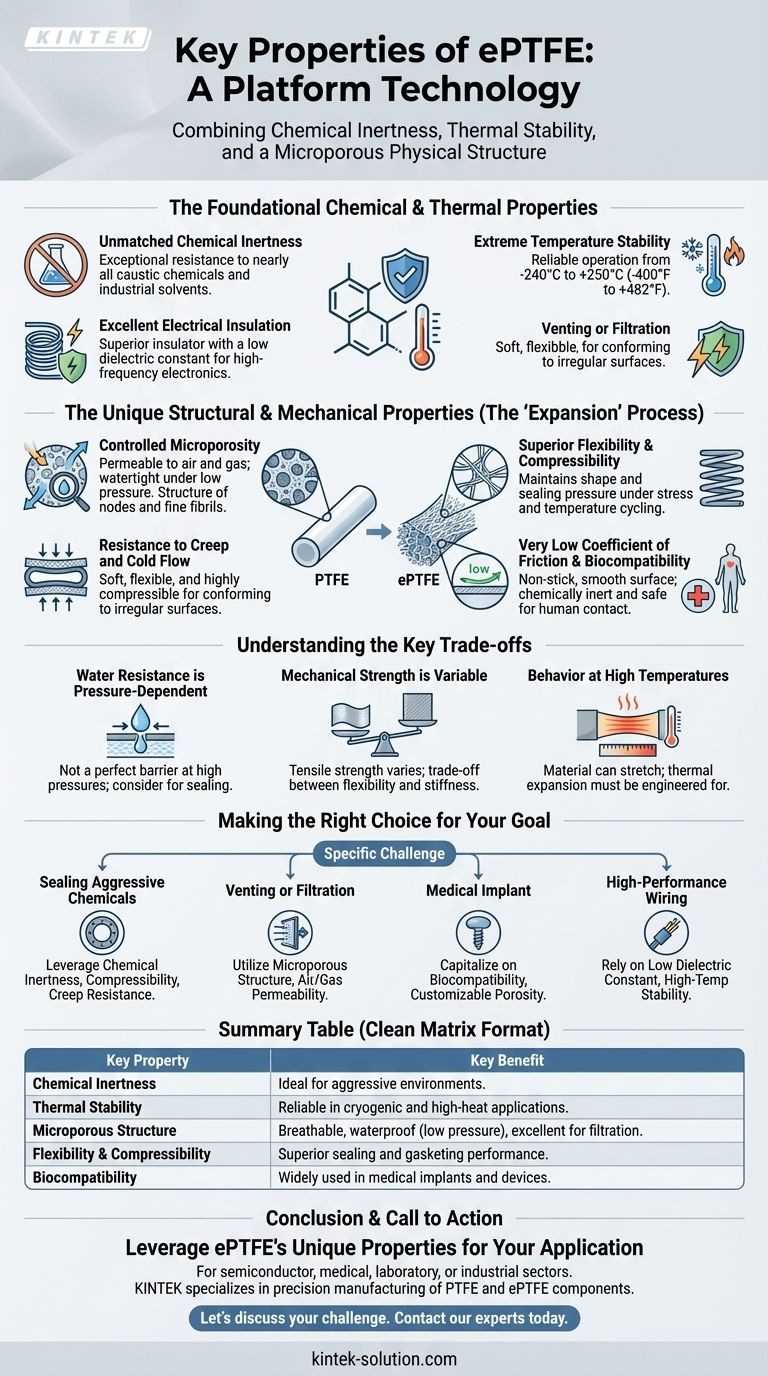

The key properties of expanded Polytetrafluoroethylene (ePTFE) are its unique combination of chemical inertness, thermal stability, and a microporous physical structure. This structure makes it highly compressible, flexible, and breathable while retaining the extreme resilience of standard PTFE.

ePTFE is not simply a material; it's a platform technology. Its defining characteristic is the creation of a microporous structure from chemically inert PTFE, which unlocks a unique combination of physical properties not found in any other single material.

The Foundational Chemical & Thermal Properties

These characteristics are inherited directly from the base PTFE polymer, providing a foundation of extreme resilience.

Unmatched Chemical Inertness

ePTFE is almost entirely chemically inactive. It exhibits exceptional resistance to nearly all caustic chemicals and industrial solvents, making it suitable for the most aggressive environments.

Extreme Temperature Stability

The material can operate reliably across a vast temperature range, typically from -240°C to +250°C (-400°F to +482°F). This allows it to maintain its integrity in both cryogenic and high-heat applications.

Excellent Electrical Insulation

ePTFE possesses a low dielectric constant, which makes it a superior insulator. This property is critical for high-frequency cables and advanced electronics where signal integrity is paramount.

The Unique Structural & Mechanical Properties

The "expansion" process is what gives ePTFE its most distinctive and versatile features, transforming solid PTFE into a flexible, porous membrane.

Controlled Microporosity

The defining feature of ePTFE is its structure of nodes interconnected by fine fibrils. This creates microscopic pores that make the material permeable to air and gas while remaining watertight under low pressure.

Superior Flexibility and Compressibility

Unlike rigid PTFE, ePTFE is exceptionally soft, flexible, and compressible. This allows it to conform to irregular surfaces, making it an ideal gasketing and sealing material.

Resistance to Creep and Cold Flow

Despite its softness, ePTFE is highly resistant to creep and cold flow. It maintains its shape and sealing pressure over time, even under significant mechanical stress and temperature cycling.

Very Low Coefficient of Friction

ePTFE has an extremely low coefficient of friction, giving it a non-stick, smooth surface. This reduces wear in dynamic applications and prevents material buildup.

Biocompatibility

The material is chemically inert and biocompatible, making it widely used in medical implants, surgical meshes, and other devices that require direct contact with the human body.

Understanding the Key Trade-offs

While powerful, the properties of ePTFE have nuances that are critical for proper application design.

Water Resistance is Pressure-Dependent

The material is hydrophobic and repels water at low pressures, but it is not a perfect waterproof barrier. High-pressure liquid can be forced through its microporous structure, a factor that must be considered in sealing applications.

Mechanical Strength is Variable

The porosity of ePTFE means its tensile strength is different from that of solid PTFE. The density and degree of expansion can be modified to prioritize properties like flexibility or stiffness, but this always involves a trade-off.

Behavior at High Temperatures

While stable at high temperatures, ePTFE is known to stretch. This thermal expansion must be accounted for in engineering designs to avoid failure or loss of sealing integrity.

Making the Right Choice for Your Goal

Selecting ePTFE is about leveraging its unique combination of properties for a specific challenge.

- If your primary focus is sealing aggressive chemicals: Leverage its chemical inertness, compressibility, and resistance to creep for a long-lasting, reliable gasket.

- If your primary focus is venting or filtration: Utilize its microporous structure, which allows air and gas to pass through while blocking liquid and particulate contaminants.

- If your primary focus is a medical implant: Capitalize on its proven biocompatibility, chemical inertness, and customizable porosity to encourage tissue integration.

- If your primary focus is high-performance wiring: Rely on its extremely low dielectric constant and high-temperature stability to ensure signal integrity in demanding electronics.

Ultimately, ePTFE's value lies in its engineered ability to solve problems that single-property materials cannot.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all caustic chemicals and solvents. | Ideal for aggressive environments. |

| Thermal Stability | Operates from -240°C to +250°C. | Reliable in cryogenic and high-heat applications. |

| Microporous Structure | Network of nodes and fibrils creating microscopic pores. | Breathable, waterproof (low pressure), excellent for filtration. |

| Flexibility & Compressibility | Soft and conformable to irregular surfaces. | Superior sealing and gasketing performance. |

| Biocompatibility | Inert and safe for contact with the human body. | Widely used in medical implants and devices. |

Leverage ePTFE's Unique Properties for Your Application

Does your project in the semiconductor, medical, laboratory, or industrial sector demand a material that combines chemical resistance, thermal stability, and microporosity? The unique properties of ePTFE make it a platform technology for solving complex challenges in sealing, filtration, venting, and medical devices.

KINTEK specializes in the precision manufacturing of high-performance PTFE and ePTFE components. We understand the nuances of this advanced material and can guide you from prototype to high-volume production, ensuring your component delivers the exact performance you need.

Let's discuss how we can apply ePTFE to your specific challenge. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What type of glass is used in glass-filled PTFE? The Definitive Answer for Superior Performance

- How do PTFE envelope gaskets perform under high pressure and temperature conditions? Unlock Reliable Sealing in Harsh Environments

- What are the characteristics of PTFE coatings? Unlock Extreme Performance for Your Components

- What are the optimal load and speed conditions for PTFE performance? Master the PV Limit for Longevity

- Why is professional consultation recommended for custom seal solutions? Mitigate Risk and Ensure Operational Integrity

- What methods are used to join or weld two PTFE sheets together? Achieve a Seamless, Leak-Proof Bond

- What are the primary applications of PTFE-lined ball valves? Control Corrosive & High-Purity Fluids

- What are the key design features of PTFE bushings? Achieve Maintenance-Free, High-Performance Bearing Solutions