In short, PTFE bearing pads are essential because they create a controlled, low-friction interface that allows massive structures to move safely. This ability to accommodate inevitable movement from thermal expansion, loads, and seismic activity prevents the buildup of destructive internal stresses, ensuring the longevity and stability of modern infrastructure like bridges and large buildings.

The core challenge in large-scale engineering isn't just supporting immense weight, but managing its movement. PTFE bearing pads solve this by isolating the structure from its foundation, providing a durable, maintenance-free surface that can slide and rotate under extreme loads.

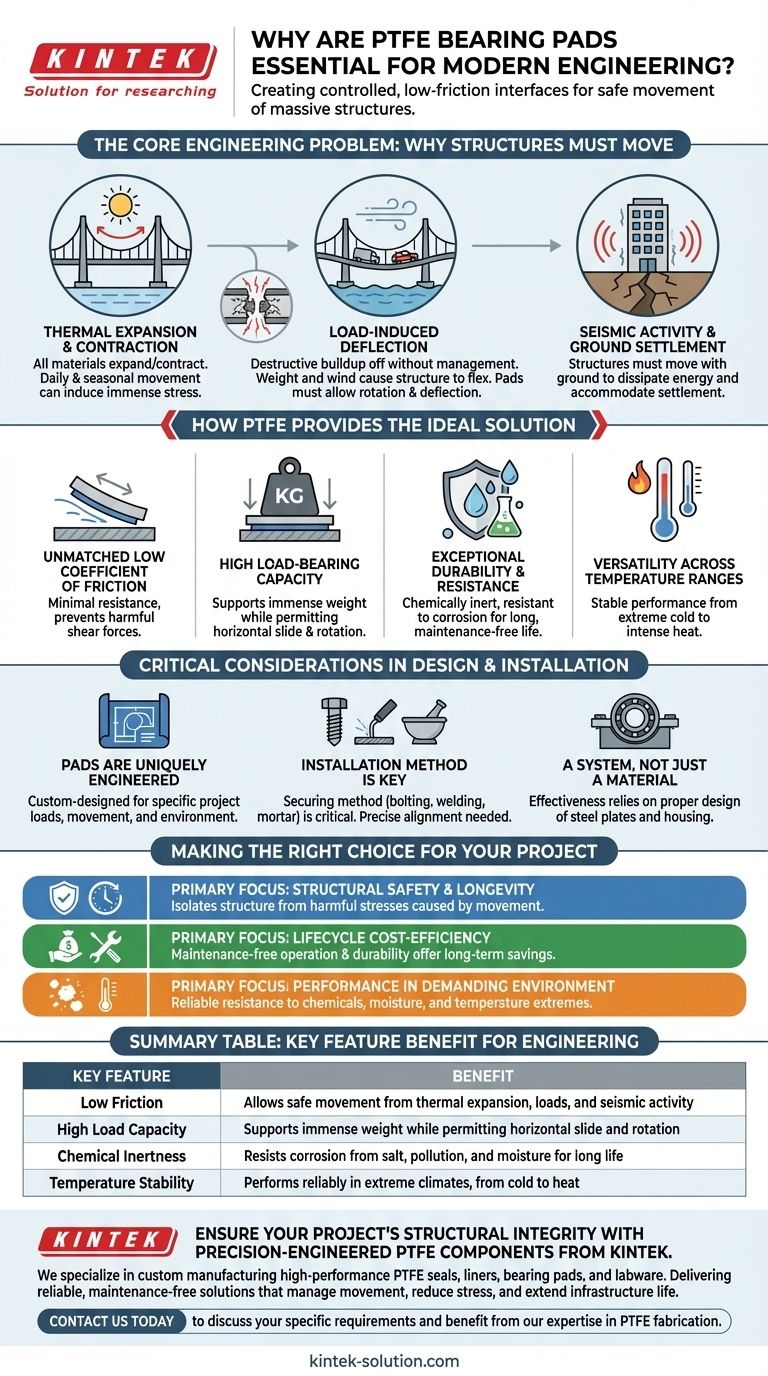

The Core Engineering Problem: Why Structures Must Move

Large structures are not rigid and static. They are dynamic systems that must be designed to accommodate constant, subtle movements to avoid catastrophic failure.

Thermal Expansion and Contraction

All materials expand when heated and contract when cooled. Over the span of a bridge or the height of a skyscraper, this daily and seasonal movement can measure several inches, inducing immense stress if not properly managed.

Load-Induced Deflection

The weight of traffic on a bridge or wind pushing against a building causes the structure to flex and deform. Bearing pads must allow for this rotation and deflection without resistance.

Seismic Activity and Ground Settlement

In seismically active regions, structures must be able to move with the ground to dissipate energy. Similarly, gradual ground settlement over time requires a flexible connection between the superstructure and its foundation.

How PTFE Provides the Ideal Solution

Polytetrafluoroethylene (PTFE) possesses a unique combination of properties that makes it exceptionally well-suited to solve the problem of structural movement.

Unmatched Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This allows structural elements to slide past each other with minimal resistance, preventing the transfer of harmful shear forces.

High Load-Bearing Capacity

Despite its slick surface, PTFE can withstand enormous vertical pressure. This allows the pads to support the immense weight of a bridge deck or building while still permitting horizontal movement.

Exceptional Durability and Resistance

PTFE is chemically inert, making it resistant to corrosion from environmental factors like road salt, pollution, and moisture. This ensures a long, maintenance-free operational life.

Versatility Across Temperature Ranges

The material's properties remain stable across a very wide range of temperatures. This ensures reliable performance in any climate, from extreme cold to intense heat.

Critical Considerations in Design and Installation

While PTFE is a highly effective material, its performance is entirely dependent on proper engineering and application. Missteps here can undermine the entire system.

Pads Are Uniquely Engineered

PTFE bearings are not off-the-shelf components. They are custom-designed for each specific project, factoring in the anticipated loads, movement range, and environmental conditions. They are rarely, if ever, reused.

Installation Method is Key

The method of securing the bearing—whether by bolting, full welding, tack welding, or mortar embedment—is critical. The PTFE surface must be protected during this process, and the pad must be perfectly aligned to ensure optimal performance.

A System, Not Just a Material

A PTFE bearing pad is part of a larger bearing assembly. Its effectiveness relies on the proper design and fabrication of the steel plates and other components that house and interact with the PTFE surface.

Making the Right Choice for Your Project

Selecting and specifying the correct bearing system is a critical decision based on the primary goals of the structure.

- If your primary focus is structural safety and longevity: PTFE's ability to isolate the structure from harmful stresses caused by movement is its most critical feature.

- If your primary focus is lifecycle cost-efficiency: The maintenance-free operation and exceptional durability of PTFE offer significant long-term cost savings.

- If your primary focus is performance in a demanding environment: PTFE's inherent resistance to chemicals, moisture, and temperature extremes makes it the most reliable choice.

Ultimately, PTFE bearing pads provide a simple, elegant, and durable solution to the complex problem of managing movement in our largest and most important structures.

Summary Table:

| Key Feature | Benefit for Engineering |

|---|---|

| Low Friction | Allows safe movement from thermal expansion, loads, and seismic activity |

| High Load Capacity | Supports immense weight while permitting horizontal slide and rotation |

| Chemical Inertness | Resists corrosion from salt, pollution, and moisture for long life |

| Temperature Stability | Performs reliably in extreme climates, from cold to heat |

Ensure your project's structural integrity with precision-engineered PTFE components from KINTEK.

We specialize in custom manufacturing high-performance PTFE seals, liners, bearing pads, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our focus on precision production delivers reliable, maintenance-free solutions that manage movement, reduce stress, and extend the life of critical infrastructure.

Contact us today to discuss your specific requirements and benefit from our expertise in PTFE fabrication.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What types of chemical solutions are PTFE control valves suitable for? Handle Corrosive Acids, Bases & More

- What are the main application areas of PTFE O-ring seals? Critical Seals for Demanding Industries

- What risks are associated with improper bonding of PTFE liners? Prevent Catastrophic Bearing Failure

- Are PTFE valves non-toxic, and why is this important? Ensure Product Purity and Safety

- Why is Teflon used in hoses? Ensuring Unmatched Reliability in Extreme Conditions

- What are the benefits of advanced PTFE compounds for temperature challenges? Achieve Unmatched Reliability in Extreme Heat

- What are the two most common materials used for backup rings? PTFE vs. PEEK for Superior Sealing

- What are the key benefits of PTFE (Teflon) gaskets? Superior Chemical & Temperature Resistance