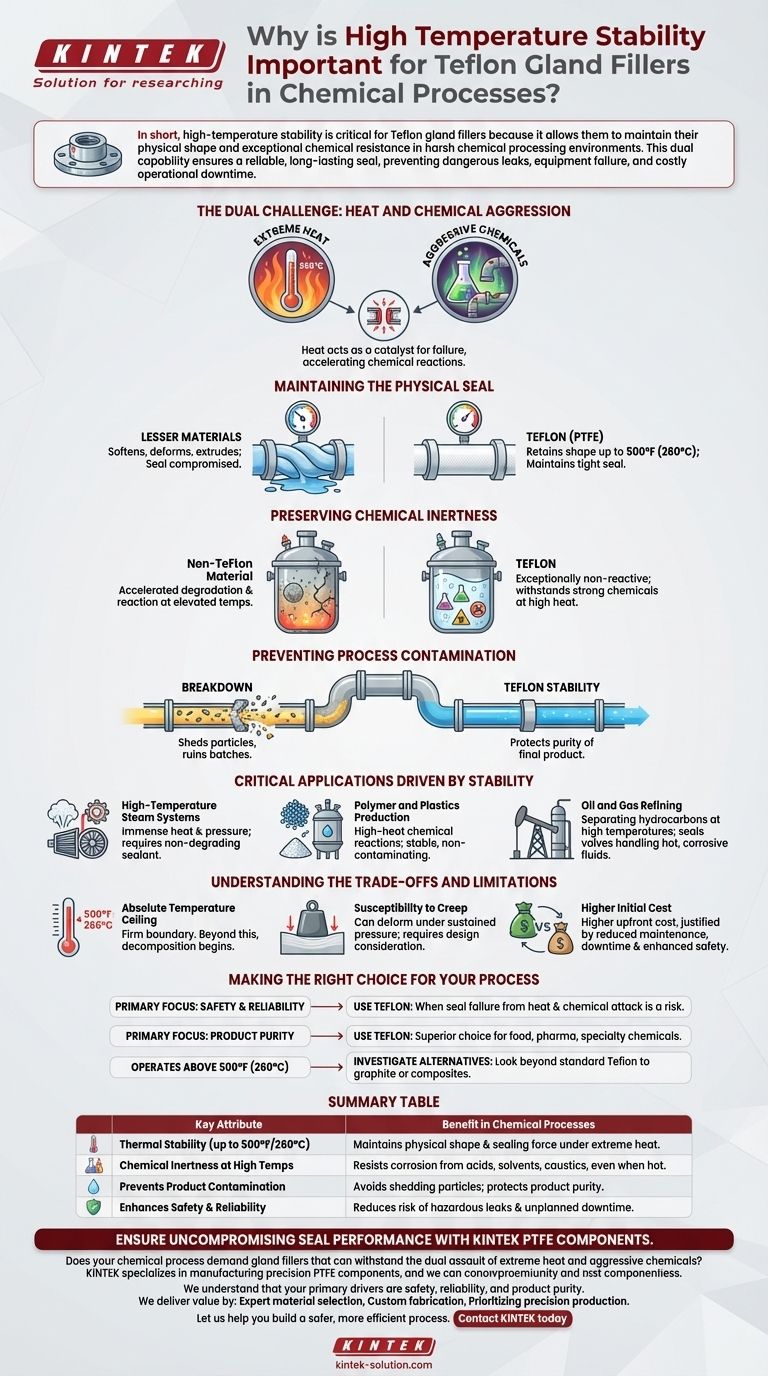

In short, high-temperature stability is critical for Teflon gland fillers because it allows them to maintain their physical shape and exceptional chemical resistance in harsh chemical processing environments. This dual capability ensures a reliable, long-lasting seal, preventing dangerous leaks, equipment failure, and costly operational downtime.

In chemical processing, a sealing material must fight a battle on two fronts: extreme heat and aggressive chemicals. Teflon's value is not just its ability to withstand high temperatures, but its unique capacity to remain chemically inert at those temperatures, preventing the failures that occur when heat compromises a material's integrity.

The Dual Challenge: Heat and Chemical Aggression

In any high-performance chemical process, a gland filler or sealant is under constant attack. High temperature acts as a catalyst for failure, making the material's inherent stability paramount.

Maintaining the Physical Seal

Heat causes lesser materials to soften, deform, or extrude under pressure. This loss of physical integrity immediately compromises the seal, leading to leaks.

Teflon's ability to remain stable up to 500°F (260°C) means it retains its shape and density, ensuring the gland packing continues to exert the necessary pressure to maintain a tight seal.

Preserving Chemical Inertness

Elevated temperatures can dramatically accelerate chemical reactions. A material that is resistant at room temperature might quickly degrade when heated in the presence of corrosive agents.

Teflon is exceptionally non-reactive, withstanding strong acids, solvents, and caustic chemicals. Crucially, it maintains this inertness at high temperatures, making it suitable for volatile applications like chlorine treatment systems and oil refining where other materials would fail.

Preventing Process Contamination

When a sealing material breaks down due to heat or chemical attack, it doesn't just fail; it can shed particles into the process stream.

This contamination can ruin product batches, damage downstream equipment, and lead to significant financial loss. Teflon's stability protects the purity of the final product.

Critical Applications Driven by Stability

The unique combination of thermal stability and chemical resistance makes Teflon gland fillers indispensable in several demanding industries.

High-Temperature Steam Systems

Steam is used for heating, sterilization, and driving turbines. These systems operate under immense heat and pressure, requiring a sealant that will not degrade or become brittle over time.

Polymer and Plastics Production

The manufacturing of polymers often involves high-heat chemical reactions. A stable, non-reactive sealant is necessary to contain these processes safely and without contaminating the resulting polymer.

Oil and Gas Refining

Refining crude oil involves separating components at very high temperatures. Teflon is used to seal valves and flanges that handle hot, corrosive hydrocarbons, where a leak would be both hazardous and costly.

Understanding the Trade-offs and Limitations

While Teflon is an exceptional material, no solution is universal. A true technical understanding requires acknowledging its operational boundaries.

The Absolute Temperature Ceiling

The specified limit of 500°F (260°C) is a firm boundary. Beyond this temperature, PTFE (Teflon) will begin to decompose, losing its properties and releasing potentially harmful fumes.

Susceptibility to Creep

Teflon is a relatively soft material and can be subject to "creep" or "cold flow," where it slowly deforms under sustained pressure. This must be accounted for in the design and tensioning of the gland packing.

Higher Initial Cost

High-performance materials like Teflon typically have a higher upfront cost than conventional packing materials. However, this cost is often justified by significantly reduced maintenance, less downtime, and enhanced operational safety.

Making the Right Choice for Your Process

Selecting the correct gland filler is a critical engineering decision based on your primary operational driver.

- If your primary focus is safety and reliability: Use Teflon in any application where a seal failure caused by combined heat and chemical attack presents a significant operational or safety risk.

- If your primary focus is product purity: Teflon is the superior choice for processes like food, pharmaceutical, or specialty chemical production where any contamination from a degrading seal is unacceptable.

- If your process operates above 500°F (260°C): You must look beyond standard Teflon and investigate alternative materials like graphite-based packing or other specialized composites designed for extreme heat.

Understanding a material's precise operational limits is the foundation for building a safer, more efficient, and more reliable process.

Summary Table:

| Key Attribute | Benefit in Chemical Processes |

|---|---|

| Thermal Stability (up to 500°F/260°C) | Maintains physical shape and sealing force under extreme heat. |

| Chemical Inertness at High Temperatures | Resists corrosion from acids, solvents, and caustics, even when hot. |

| Prevents Product Contamination | Avoids shedding particles into process streams, protecting product purity. |

| Enhances Safety & Reliability | Reduces the risk of hazardous leaks and unplanned equipment downtime. |

Ensure Uncompromising Seal Performance with KINTEK PTFE Components

Does your chemical process demand gland fillers that can withstand the dual assault of extreme heat and aggressive chemicals? The high-temperature stability of Teflon is critical for preventing leaks, contamination, and costly downtime.

KINTEK specializes in manufacturing precision PTFE components—including seals, gland fillers, liners, and custom labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We understand that your primary drivers are safety, reliability, and product purity.

We deliver value by:

- Providing expert material selection to ensure your components perform within their precise operational limits.

- Offering custom fabrication from prototypes to high-volume orders, tailored to your specific process requirements.

- Prioritizing precision production for consistent, reliable performance that protects your equipment and your product.

Let us help you build a safer, more efficient process. Contact KINTEK today to discuss your application and receive a quote for high-performance PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the recommended processing parameters for CNC machining PTFE? Master Heat Control for Precision Parts

- What temperature can PTFE sheets withstand? From -200°C to +260°C with Unmatched Stability

- In what applications are PTFE-lined bearings particularly beneficial? For Maintenance-Free Performance in Harsh Environments

- What is the temperature resistance performance of PTFE? Master Its -200°C to +260°C Range

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- What is the best PTFE material for cryogenic gas applications? mPTFE Ensures Leak-Proof Sealing

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE perform when bearing surfaces become contaminated? Maintain Reliable Performance in Unclean Environments