At its core, the flexibility of a Polytetrafluoroethylene (PTFE) oil seal is critical because it ensures the seal can maintain constant, reliable contact with a shaft even under imperfect conditions. This adaptability allows it to compensate for shaft surface irregularities, dynamic stresses like vibration, and significant temperature fluctuations, preventing leaks where more rigid materials would fail.

While PTFE is known for its temperature and chemical resistance, its flexibility is the key characteristic that guarantees its performance in the real world. This adaptability translates directly into enhanced durability, versatility, and long-term reliability for critical machinery.

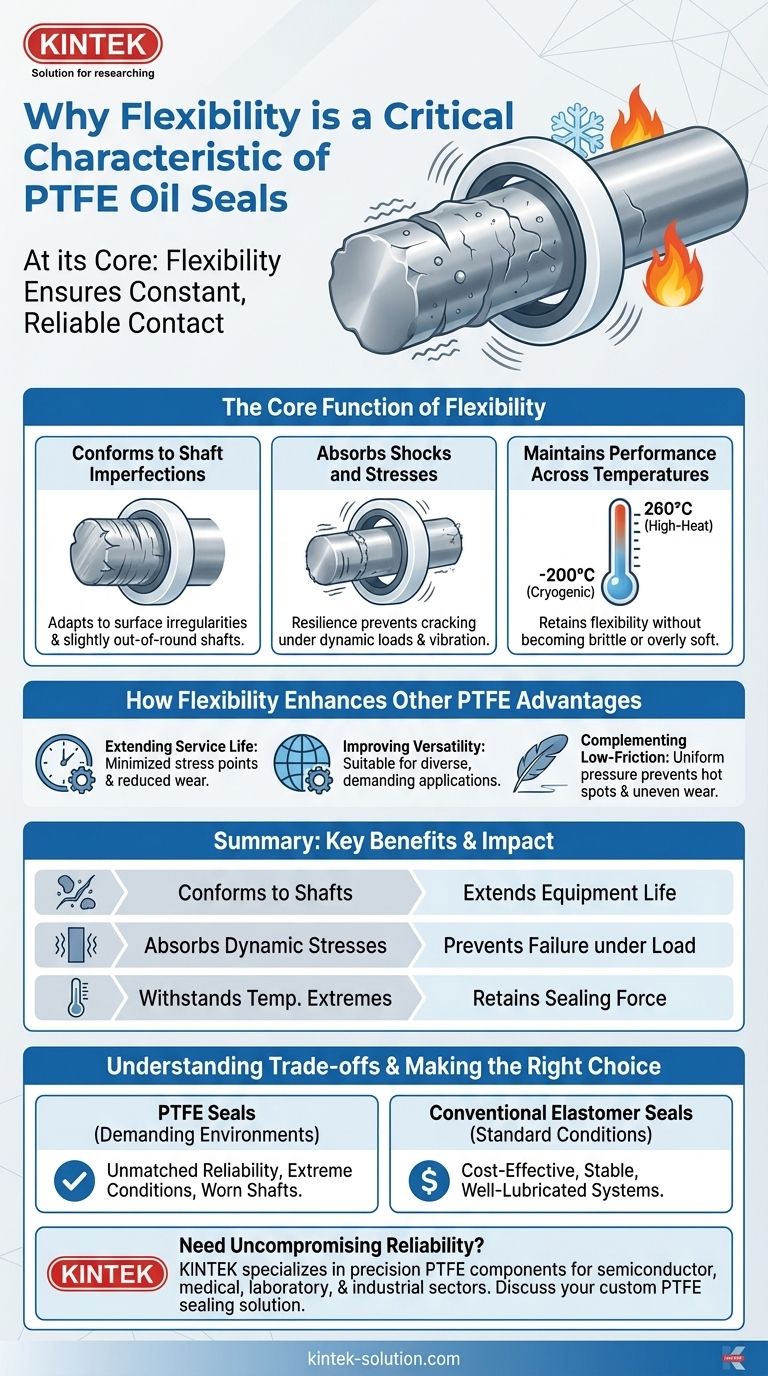

The Core Function of Flexibility: Ensuring Seal Integrity

The primary job of any seal is to prevent leakage. Flexibility is the mechanical property that allows a PTFE seal to accomplish this task under dynamic and often unpredictable operating conditions.

Conforming to Shaft Imperfections

No rotating shaft is perfectly smooth or perfectly round, especially after a period of service.

Flexibility allows the PTFE seal lip to conform precisely to the microscopic peaks and valleys on a shaft's surface. This is especially critical for creating a reliable seal on worn, scored, or slightly out-of-round shafts, extending the life of existing equipment.

Absorbing Shocks and Stresses

Mechanical systems are subject to vibration, shaft runout, and axial movement. A rigid seal material would be prone to failure under these stresses.

The inherent elasticity of PTFE allows the seal to absorb these dynamic loads and maintain contact with the shaft without cracking or permanent deformation. This resilience is fundamental to its long-term durability in demanding applications like automotive engines and industrial gearboxes.

Maintaining Performance Across Wide Temperatures

PTFE is famous for its exceptionally wide operating temperature range, from as low as -200°C to as high as 260°C.

Its ability to retain flexibility at both temperature extremes is crucial. Unlike some elastomers that become brittle and crack in the cold or overly soft at high heat, PTFE maintains its shape and sealing force, ensuring consistent performance whether in cryogenic applications or high-heat engines.

How Flexibility Enhances Other PTFE Advantages

Flexibility does not exist in a vacuum. It works in concert with other material properties to make PTFE a superior sealing solution.

Extending Service Life

The primary failure mode for many seals is cracking or wear caused by stress.

By absorbing vibrations and conforming to the shaft, a flexible PTFE seal minimizes localized stress points. This, combined with its low-friction nature, dramatically reduces wear and prevents the material fatigue that leads to premature failure, directly contributing to a longer service life and reduced maintenance.

Improving Application Versatility

A seal that only works in perfect conditions has limited use.

Because its flexibility allows it to handle shaft imperfections, temperature swings, and chemical exposure, a single PTFE seal design can be used across a vast range of applications. This makes it a versatile choice for industries from aerospace and automotive to chemical processing.

Complementing Low-Friction Properties

PTFE has one of the lowest coefficients of friction of any solid material, which helps reduce energy loss and heat generation.

Flexibility ensures the seal lip applies uniform, gentle pressure around the entire shaft circumference. This even contact maximizes the benefit of the low-friction surface, preventing hot spots and uneven wear that could otherwise compromise the seal.

Understanding the Trade-offs: PTFE vs. Conventional Seals

While PTFE offers superior performance in many areas, it is essential to understand its context relative to traditional seal materials.

The Performance Advantage of PTFE

PTFE seals are the definitive choice for demanding environments. They outperform conventional elastomer (rubber) seals in temperature resistance, chemical stability, and the ability to function in dry-running or poorly lubricated conditions. Their flexibility gives them a decisive edge in reliability on imperfect or dynamic shafts.

The Role of Conventional Elastomer Seals

Despite the advantages of PTFE, conventional oil seals remain a highly viable and cost-effective solution for many common applications. In stable, well-lubricated systems without chemical or temperature extremes, a standard elastomer seal performs its function reliably at a lower price point.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision that balances performance requirements with budget constraints.

- If your primary focus is reliability in demanding environments: Choose a PTFE seal for its unmatched adaptability to worn shafts, extreme temperatures, aggressive chemicals, and dynamic stress.

- If your primary focus is cost-effectiveness in standard conditions: A conventional elastomer seal is often the most practical and economical choice for stable, well-lubricated systems.

Ultimately, choosing the right seal is about matching the material's capabilities to the operational reality of your equipment to ensure long-term integrity.

Summary Table:

| Key Benefit of Flexibility | Impact on Seal Performance |

|---|---|

| Conforms to Shaft Imperfections | Creates a reliable seal on worn or imperfect shafts, extending equipment life. |

| Absorbs Dynamic Stresses | Maintains contact and prevents failure under vibration, runout, and axial movement. |

| Withstands Temperature Extremes | Retains sealing force and performance from -200°C to 260°C without becoming brittle or soft. |

Need a PTFE seal that delivers uncompromising reliability?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom oil seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals are engineered for maximum flexibility and durability, providing a leak-free solution that withstands harsh conditions, reduces maintenance, and extends equipment service life.

From prototype to high-volume production, we deliver the precision and quality your critical applications demand.

Contact KINTEK today to discuss your custom PTFE sealing solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is the high-temperature tolerance of PTFE gaskets important? Ensure Reliable Sealing in Extreme Heat

- How does glass-filled PTFE differ from pure PTFE? A Guide to Enhanced Mechanical Performance

- What are the general properties and applications of Teflon industrial coatings? Solve Complex Engineering Challenges

- What industries are spiral PTFE backup rings ideal for? Achieve Superior Sealing in Extreme Conditions

- How do PTFE valves and components support high-purity liquid transfer? Ensure Product Integrity with Inert Materials

- What are the benefits of PTFE's low friction coefficient in shaft seals? Boost Efficiency & Extend Equipment Life

- Why are PTFE seals ideal for the chemical and petrochemical industries? Unmatched Chemical & Thermal Resistance

- What are the key components of Metal-Polymer Bronze Backed PTFE Plain Bearings? A Guide to Their Layered Design