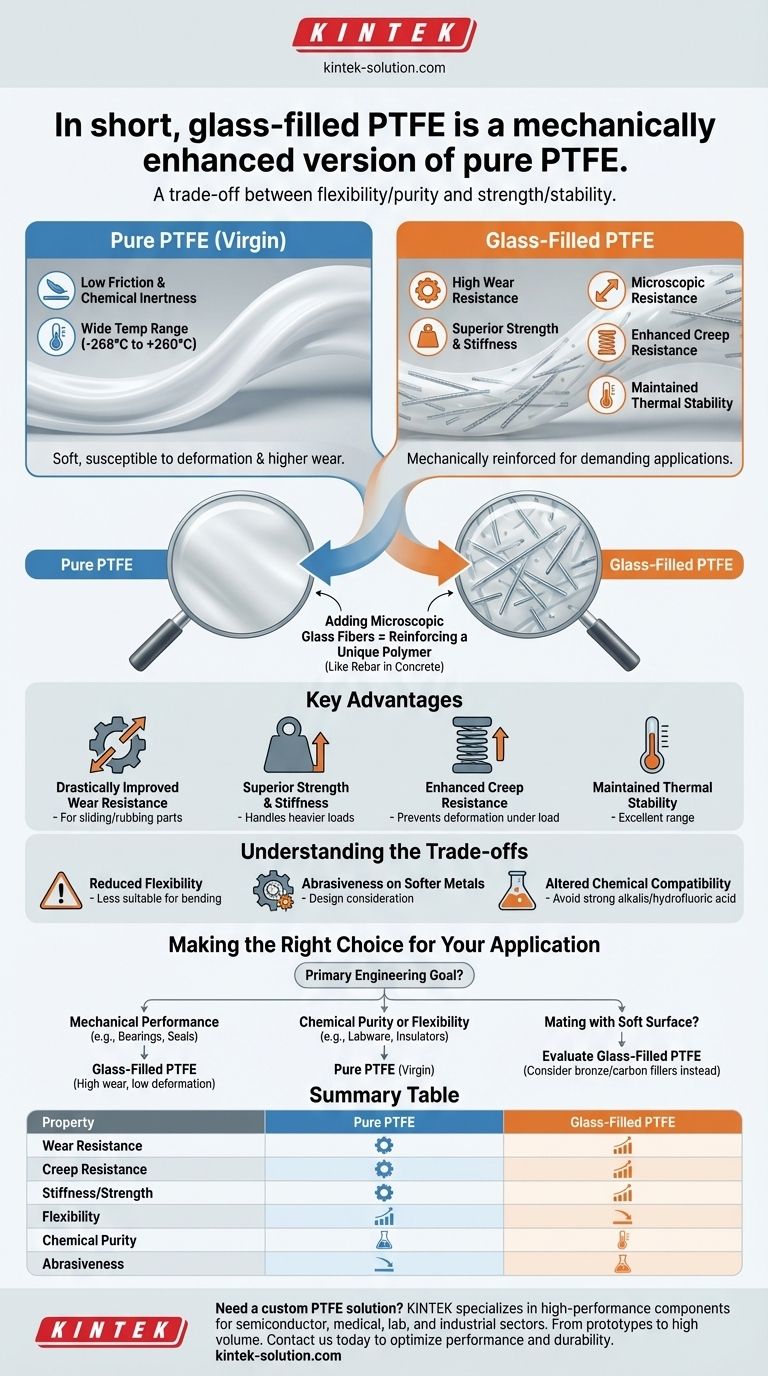

In short, glass-filled PTFE is a mechanically enhanced version of pure PTFE. By adding microscopic glass fibers to the polytetrafluoroethylene (PTFE) matrix, the resulting material gains significant improvements in wear resistance, compression strength, and resistance to "creep" or deformation under load.

The fundamental choice between pure and glass-filled PTFE is a trade-off. You sacrifice some of the flexibility and absolute chemical purity of virgin PTFE to gain a material with far greater dimensional stability and durability for demanding mechanical applications.

The Core Difference: Reinforcing a Unique Polymer

To understand the distinction, we first need to appreciate the properties of each component.

The Nature of Virgin PTFE

Virgin PTFE is a remarkable material known for its extremely low coefficient of friction (it's one of the most slippery substances known), exceptional chemical inertness, and a wide operating temperature range.

However, pure PTFE is also relatively soft. This can lead to deformation under sustained pressure (creep) and higher wear rates in dynamic applications.

How Glass Fibers Change the Matrix

By adding a filler, in this case, small E-glass fibers, the properties of the PTFE base are fundamentally altered. These fibers act like rebar in concrete, creating a composite material that is much stronger and more rigid.

The glass used is a specific type known for its electrical insulating properties, and the fibers are incredibly small, ensuring they are well-dispersed throughout the PTFE.

Key Advantages of Glass-Filled PTFE

Adding glass provides a set of targeted mechanical improvements, making the material suitable for a new class of applications.

Drastically Improved Wear Resistance

The glass fibers significantly increase the material's ability to withstand abrasion and friction. This makes it ideal for components that slide or rub against other parts, such as self-lubricating bearings and wear strips.

Superior Strength and Stiffness

Glass-filled PTFE is much stronger and stiffer than its pure counterpart. This translates to higher compressive strength, meaning it can handle heavier loads without being crushed or losing its shape.

Enhanced Creep Resistance

Creep is the tendency of a material to slowly deform over time when under a constant load. The reinforcing glass fibers prevent this, ensuring components like gaskets and seals maintain their integrity and sealing force over long periods.

Maintained Thermal Stability

Glass-filled PTFE retains the excellent temperature range of virgin PTFE, performing consistently from approximately -268°C to +260°C (-450°F to +500°F). It also performs very well in oxidizing environments.

Understanding the Trade-offs

The improvements offered by glass-filled PTFE come with important considerations that may make it unsuitable for certain scenarios.

Reduced Flexibility

The added stiffness means the material is far less flexible. For applications requiring the material to bend or conform to tight radii, virgin PTFE is the superior choice.

Abrasiveness on Softer Metals

While excellent for wear resistance, the glass fibers can be more abrasive to softer mating surfaces (like aluminum or brass) than unfilled PTFE. This is a critical design consideration in dynamic sealing or bearing applications.

Altered Chemical Compatibility

While still highly inert, glass-filled PTFE is not recommended for use with certain substances that attack glass, such as strong alkalis or hydrofluoric acid. In these specific cases, virgin PTFE offers superior chemical resistance.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary engineering goal.

- If your primary focus is mechanical performance: Choose glass-filled PTFE for applications like bearings, compressor rings, seals, and gaskets that require high wear resistance and minimal deformation under load.

- If your primary focus is chemical purity or flexibility: Select virgin PTFE for laboratory equipment, electrical insulators, or when dealing with chemicals known to attack glass.

- If your component mates with a soft surface: Carefully evaluate glass-filled PTFE, as another filler (like bronze or carbon) might be a more suitable choice to prevent premature wear on the mating part.

By understanding this balance between mechanical reinforcement and inherent properties, you can select the precise PTFE formulation that delivers the performance your application demands.

Summary Table:

| Property | Pure PTFE | Glass-Filled PTFE |

|---|---|---|

| Wear Resistance | Low | High |

| Creep Resistance | Low | High |

| Stiffness/Strength | Low | High |

| Flexibility | High | Low |

| Chemical Purity | Highest | Slightly Reduced |

| Abrasiveness to Mating Surfaces | Low | Higher |

Need a custom PTFE solution for your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the mechanical strength of glass-filled PTFE or the chemical purity of virgin PTFE, our precision production and custom fabrication services ensure you get the right material for your needs, from prototypes to high-volume orders.

Contact us today to discuss your project and let our experts help you optimize performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Parts Manufacturer Conductive Glass Substrate Cleaning Rack

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support