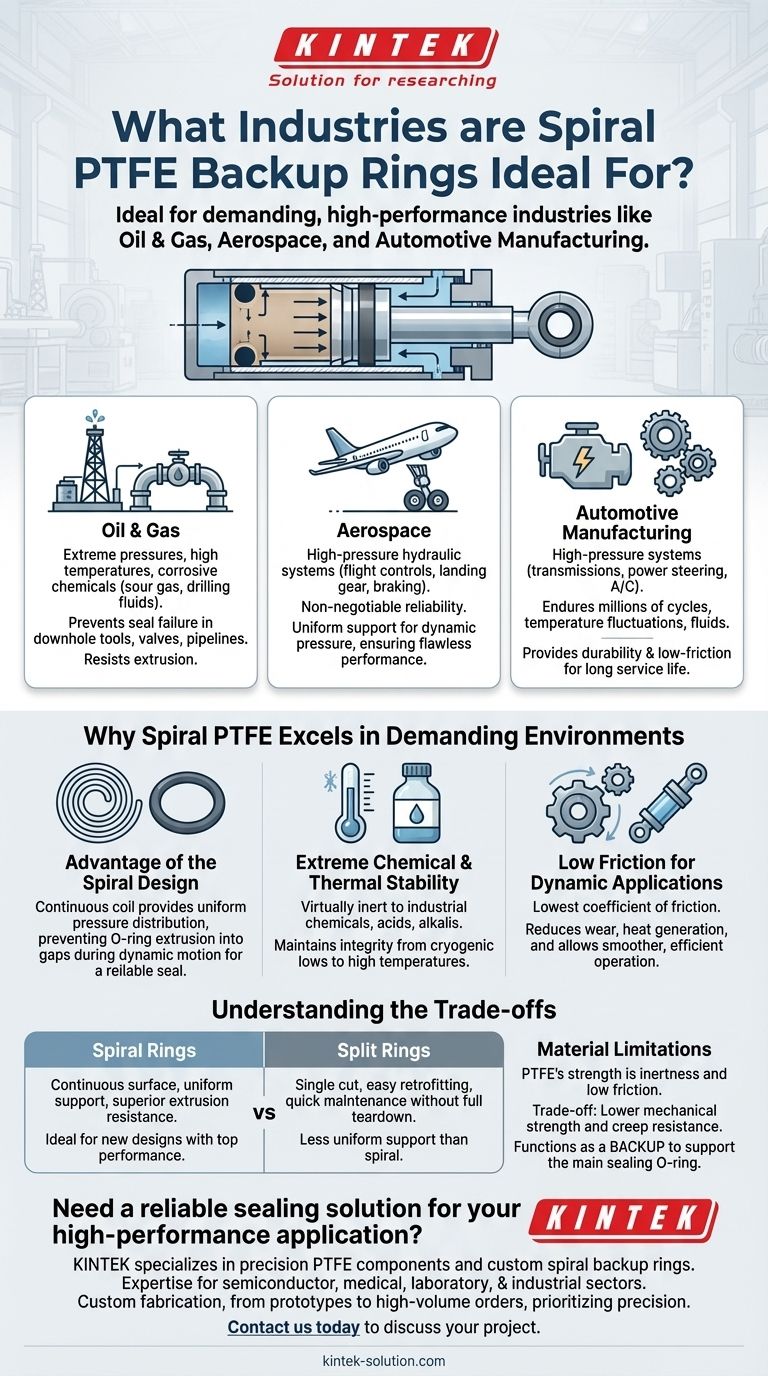

In short, spiral PTFE backup rings are ideal for demanding, high-performance industries like oil and gas, aerospace, and automotive manufacturing. Their unique coiled construction and the inherent properties of PTFE make them exceptionally well-suited for applications involving high pressure, aggressive chemicals, and dynamic motion where standard seals would fail.

The specific industry is less important than the operating conditions. Spiral PTFE backup rings are chosen when an application demands superior resistance to O-ring extrusion under a combination of high pressure, wide temperature ranges, and chemical exposure.

Why Spiral PTFE Excels in Demanding Environments

The effectiveness of a spiral PTFE backup ring stems from two factors: the properties of the material (PTFE) and the advantages of the spiral design.

The Advantage of the Spiral Design

A spiral backup ring is made from a continuous coil of PTFE. This design provides uniform pressure distribution around the entire circumference of the O-ring it supports.

This continuous contact prevents the O-ring from being extruded into gaps under high pressure, especially during dynamic motion, ensuring a more reliable and longer-lasting seal.

Extreme Chemical and Thermal Stability

PTFE is virtually inert to most industrial chemicals, acids, and alkalis. This makes it a necessary choice for equipment in chemical processing or oil and gas extraction.

Furthermore, it maintains its integrity and properties across an exceptionally wide temperature range, from cryogenic lows to high-temperature engine compartments.

Low Friction for Dynamic Applications

PTFE has one of the lowest coefficients of friction of any solid material. This is a critical advantage in dynamic sealing applications like hydraulic cylinders, pumps, and actuators.

Lower friction reduces wear on the O-ring and mating surfaces, decreases heat generation, and allows for smoother, more efficient operation.

Key Industrial Applications in Detail

Understanding the specific challenges within each industry clarifies why the spiral PTFE ring is often the superior technical choice.

Oil & Gas

This industry is characterized by extreme pressures, high temperatures, and exposure to corrosive chemicals like sour gas and drilling fluids. Spiral PTFE backup rings are essential for preventing seal failure in downhole tools, valves, and pipelines.

Aerospace

Aerospace systems rely on high-pressure hydraulic systems for flight controls, landing gear, and braking. The reliability of these seals is non-negotiable.

The spiral ring's ability to provide uniform support under dynamic pressure ensures that hydraulic actuators perform flawlessly and without leakage, which is critical for safety.

Automotive Manufacturing

Modern vehicles use high-pressure systems for transmissions, power steering, and air conditioning. These components must endure millions of cycles, temperature fluctuations, and exposure to various oils and fluids.

Spiral PTFE backup rings provide the durability and low-friction performance needed to ensure a long service life for these critical automotive seals.

Understanding the Trade-offs

While powerful, the spiral PTFE backup ring is not a universal solution. Understanding its context compared to alternatives is key to proper selection.

Spiral vs. Split Rings

Split PTFE rings have a single cut, allowing them to be opened and installed over a shaft without full system disassembly. This makes them ideal for retrofitting or quick maintenance.

However, the continuous, uninterrupted surface of a spiral ring generally provides more uniform support and superior resistance to extrusion, making it the preferred choice for new designs where performance is the top priority.

Material Limitations

PTFE's greatest strengths are its chemical inertness and low friction. Its primary trade-off is relatively lower mechanical strength and resistance to creep compared to other engineering plastics.

This is why it functions perfectly as a backup ring—it supports the more elastic O-ring, which does the primary sealing, rather than acting as the main structural component itself.

Making the Right Choice for Your Application

Your selection should be driven by the specific demands of your system and its lifecycle.

- If your primary focus is maximum sealing integrity in a new design: The uniform support of a spiral PTFE backup ring is the optimal choice for high-pressure, dynamic applications.

- If your primary focus is ease of maintenance or retrofitting an existing system: A split PTFE backup ring offers significant advantages, as it can be installed without a complete teardown.

- If your primary focus is extreme chemical or thermal resistance: Any PTFE backup ring is a strong choice, but the spiral design provides the best defense against extrusion when high pressure is also a factor.

Ultimately, choosing the right backup ring is about matching the component's unique design strengths to your specific operational demands.

Summary Table:

| Industry | Key Application | Primary Benefit |

|---|---|---|

| Oil & Gas | Downhole tools, valves, pipelines | Resists extrusion from extreme pressure & chemicals |

| Aerospace | Flight controls, landing gear hydraulics | Ensures reliability & safety in critical systems |

| Automotive | Transmissions, power steering, A/C | Provides durability for millions of operational cycles |

Need a reliable sealing solution for your high-performance application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom spiral backup rings. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your seals can withstand extreme pressure, aggressive chemicals, and wide temperature ranges.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact us today to discuss your project and discover how our PTFE components can enhance your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions