In high-purity systems, your components are not just passive conduits; they are active participants in maintaining purity. Polytetrafluoroethylene (PTFE) valves and components support these applications because the material possesses three core properties: it is exceptionally non-reactive (chemically inert), non-toxic, and features an ultra-smooth surface that resists the buildup of particles and microbes.

The central challenge in any high-purity liquid transfer is preventing the system itself from becoming a source of contamination. PTFE excels because it is fundamentally inert, meaning it will not leach chemicals into the fluid, and its non-stick surface actively prevents contaminants from adhering to it.

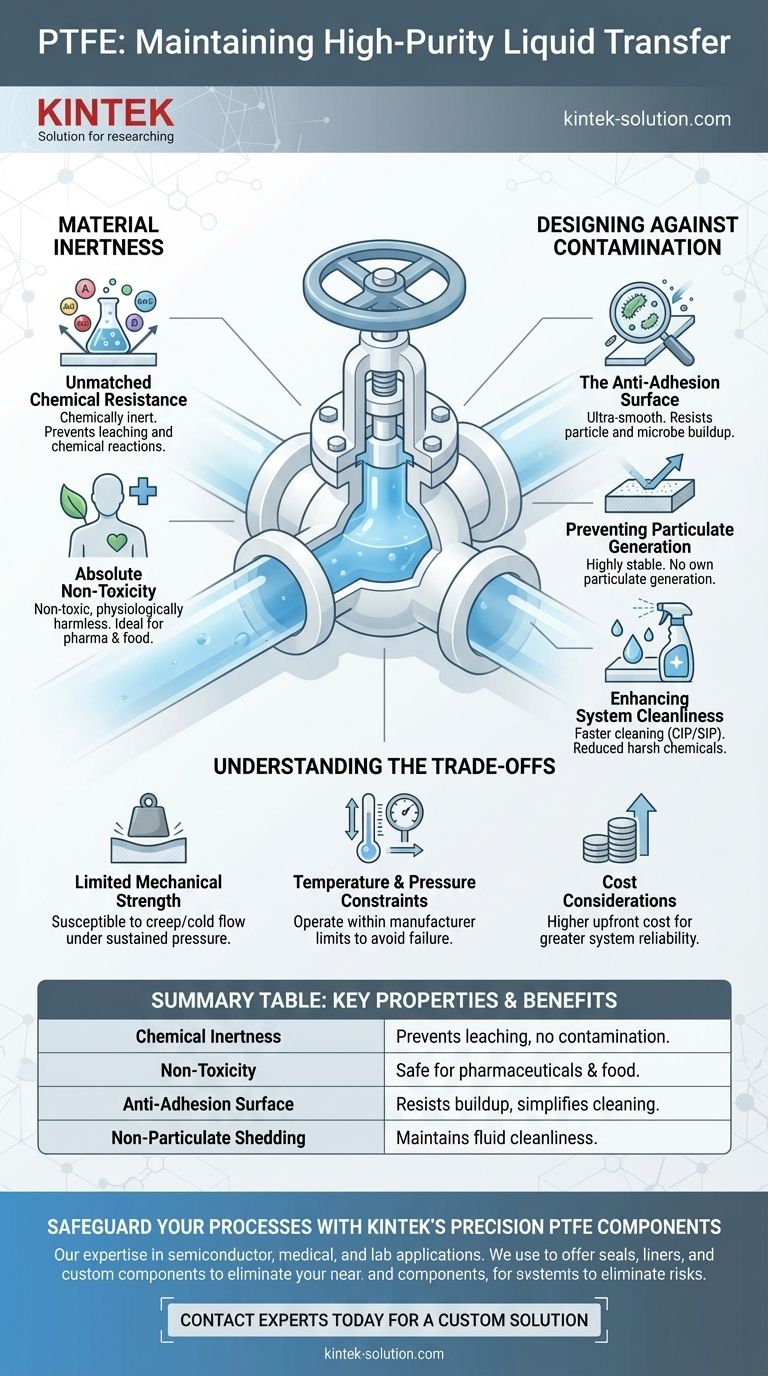

The Foundation of Purity: Material Inertness

The primary value of PTFE in high-purity applications begins at the molecular level. Its stability ensures that the material itself does not compromise the fluid it is transporting.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It does not react with nearly all industrial chemicals, acids, and bases.

This inertness is critical because it prevents leaching, a process where the component material breaks down and dissolves into the fluid, introducing impurities.

Absolute Non-Toxicity

PTFE is a non-toxic and physiologically harmless material, often compliant with FDA and USP Class VI requirements.

This makes it an essential choice for applications where the end product is intended for human use, such as in the pharmaceutical, food, and beverage industries.

Designing Against Contamination

Beyond its chemical makeup, the physical characteristics of PTFE are uniquely suited to prevent the introduction and buildup of external contaminants.

The Anti-Adhesion Surface

The surface of PTFE is incredibly smooth and has a very low coefficient of friction, which is what gives it its famous "non-stick" quality.

In high-purity systems, this means there are no microscopic pits or crevices where particulates or bacteria can lodge and colonize, which is a common failure point for other materials.

Preventing Particulate Generation

Unlike some plastics or metals that can degrade and shed their own particles over time, PTFE is a highly stable material.

It does not generate its own particulates, ensuring that the only thing moving through the system is the intended pure liquid. This is especially vital in industries like semiconductor manufacturing, where a single particle can ruin a microchip.

Enhancing System Cleanliness

The non-stick surface makes cleaning protocols, such as Clean-in-Place (CIP) and Sterilize-in-Place (SIP), faster and more effective.

Because contaminants cannot adhere strongly to the surface, they are flushed away easily, reducing the use of harsh cleaning agents and simplifying process validation.

Understanding the Trade-offs

While PTFE is an exceptional material for purity, it is not a universal solution. Acknowledging its limitations is key to proper system design.

Limited Mechanical Strength

Compared to metals, PTFE is a relatively soft material. It can be susceptible to creep or cold flow, where the material slowly deforms under sustained pressure.

This requires careful engineering in valve seats and seals to ensure long-term performance without leaks, especially in high-pressure applications.

Temperature and Pressure Constraints

While PTFE has a wide operational temperature range, it cannot match the performance of stainless steel or specialty alloys at extreme high temperatures and pressures.

System designers must operate within the manufacturer's specified limits for PTFE components to avoid mechanical failure.

Cost Considerations

High-purity PTFE components are typically more expensive than those made from standard plastics or even some stainless steels.

However, this higher upfront cost is often justified by the reduced risk of batch contamination, improved product yields, and greater system reliability.

Making the Right Choice for Your System

Selecting PTFE is a strategic decision based on the specific purity requirements of your process.

- If your primary focus is preventing chemical leaching (e.g., aggressive chemical processing): PTFE's complete chemical inertness is its most critical feature, ensuring your product remains uncontaminated by the equipment.

- If your primary focus is maintaining biological purity (e.g., biopharma, food): PTFE's non-toxic nature and smooth, anti-adhesion surface are paramount to prevent microbial growth and ensure product safety.

- If your primary focus is eliminating particulate contamination (e.g., semiconductor manufacturing): PTFE's non-shedding and non-stick properties ensure the highest level of fluid cleanliness required for sensitive electronics.

Ultimately, choosing PTFE is an investment in the integrity and reliability of your entire high-purity process.

Summary Table:

| Key Property | Benefit for High-Purity Systems |

|---|---|

| Chemical Inertness | Prevents leaching, ensuring no chemical contamination. |

| Non-Toxicity | Safe for pharmaceuticals, food, and beverage applications. |

| Anti-Adhesion Surface | Resists particle buildup and microbial growth, simplifying cleaning. |

| Non-Particulate Shedding | Maintains fluid cleanliness critical for semiconductors and labs. |

Safeguard your high-purity processes with KINTEK's precision PTFE components.

For semiconductor, medical, laboratory, and industrial applications, even minor contamination can compromise product quality and yield. KINTECH specializes in manufacturing high-purity PTFE seals, liners, labware, and custom components that leverage the material's full inert and non-stick properties. We ensure precision production and offer custom fabrication from prototypes to high-volume orders, helping you eliminate contamination risks and enhance system reliability.

Contact our experts today to discuss your specific requirements and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Microwave Digestion Vessels for Demanding Applications

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the common applications of PTFE pneumatic valves? Ensure Purity and Chemical Resistance in Your Process

- What guidelines apply to machining oil grooves in PTFE pads? Achieve Precision & Avoid Common Pitfalls

- What are PTFE envelope gaskets used for? Protect Delicate Flanges & Seal Aggressive Chemicals

- What are the advantages of square cross-section ring seals in TFE Encapsulated gaskets? Achieve Superior, Reliable Sealing

- What are spring-energized PTFE seals and how do they work? Achieve Leak-Proof Reliability in Extreme Conditions

- What are the key features of PTFE ball valves? Superior Chemical Resistance & Reliable Flow Control

- Why are PTFE lined valves preferred globally? Achieve Superior Corrosion Resistance & Cost Savings

- What is a PTFE bush and what is its primary use? A Guide to Self-Lubricating Bearings