In short, PTFE seals are ideal for chemical and petrochemical applications due to their nearly universal chemical inertness, which prevents degradation from aggressive acids, bases, and solvents. This core property is supported by a wide operational temperature range and an exceptionally low coefficient of friction, ensuring reliability and efficiency in the harshest industrial environments.

The decision to use PTFE is not merely about selecting a material; it is about investing in operational integrity. Its unique combination of chemical, thermal, and mechanical properties makes it a foundational component for ensuring safety and uptime where other materials would quickly fail.

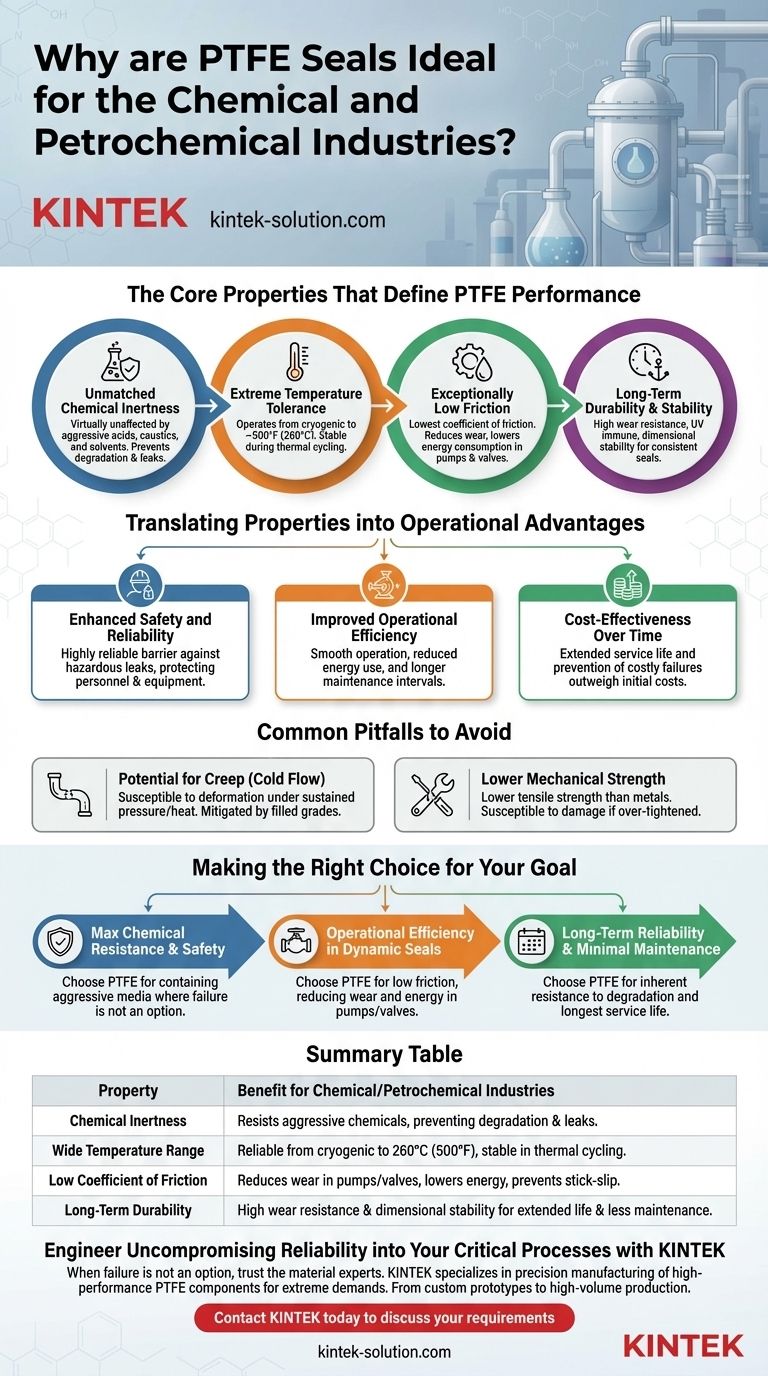

The Core Properties That Define PTFE Performance

To understand why PTFE (Polytetrafluoroethylene) is so dominant in these industries, we must look at its fundamental material characteristics. These properties work in concert to deliver unparalleled performance in demanding conditions.

Unmatched Chemical Inertness

PTFE is chemically inert to a degree that is almost unmatched by any other polymer. It is virtually unaffected by the most aggressive acids, caustics, and solvents.

This means a PTFE seal will not swell, dissolve, or degrade when exposed to corrosive media, preventing catastrophic leaks and ensuring process purity. Even boiling in concentrated sulfuric or nitric acid will not affect it.

Extreme Temperature Tolerance

Chemical processes rarely occur at room temperature. PTFE seals maintain their integrity across a vast temperature range, from cryogenic levels up to approximately 500°F (260°C).

This thermal stability ensures a reliable seal during temperature cycling, a common occurrence in reactors, heat exchangers, and distillation columns.

Exceptionally Low Friction

PTFE has the lowest coefficient of friction of any known solid material. For sealing applications, this translates directly to higher efficiency and longevity.

In dynamic equipment like pumps and valves, this high lubricity reduces wear on moving parts, lowers energy consumption, and prevents the stick-slip phenomenon that can compromise sealing performance.

Long-Term Durability and Stability

Beyond its primary attributes, PTFE exhibits high wear resistance and is immune to degradation from UV exposure, which can cause other plastics to become brittle over time.

It also maintains its shape and size (dimensional stability) when immersed in various fluids, ensuring a consistent and reliable seal throughout its service life.

Translating Properties into Operational Advantages

These material properties are not just academic; they provide tangible benefits that directly impact a facility's safety, efficiency, and bottom line.

Enhanced Safety and Reliability

The primary role of a seal in the chemical industry is containment. Because PTFE does not corrode or degrade, it provides a highly reliable barrier against leaks of hazardous or volatile chemicals.

This fundamental reliability is the cornerstone of plant safety, protecting personnel, the environment, and expensive equipment like reactors and pumps.

Improved Operational Efficiency

The low-friction nature of PTFE seals means that equipment runs more smoothly. Pumps require less energy to operate, and valve stems are easier to actuate.

This durability also leads to longer intervals between maintenance, reducing costly downtime and increasing overall plant productivity.

Cost-Effectiveness Over Time

While PTFE may have a higher upfront material cost compared to some conventional elastomers, its extended service life and the prevention of costly failures make it a highly cost-effective solution.

The expense of a single production halt or safety incident caused by a failed seal far outweighs the initial investment in a superior sealing material.

Common Pitfalls to Avoid

Despite its exceptional properties, specifying PTFE requires an understanding of its limitations to prevent misapplication.

Potential for Creep (Cold Flow)

PTFE is a relatively soft material and can be susceptible to creep, or cold flow, where it slowly deforms under sustained pressure, especially at elevated temperatures. This can lead to a loss of sealing pressure over time.

This is often mitigated by using filled grades of PTFE, which incorporate materials like glass fiber, carbon, or bronze to enhance mechanical strength and resistance to creep.

Lower Mechanical Strength

Compared to metals, PTFE has lower tensile strength and is more susceptible to damage during installation if not handled properly. Over-tightening flanges, for example, can crush a PTFE gasket and compromise its sealing ability.

Making the Right Choice for Your Goal

Selecting the right sealing material is a critical engineering decision. Your primary operational goal will determine why PTFE is often the superior choice.

- If your primary focus is maximum chemical resistance and safety: PTFE is the default choice for containing the most aggressive and hazardous media where material failure is not an option.

- If your primary focus is operational efficiency in dynamic seals: The low-friction properties of PTFE are essential for reducing wear, minimizing energy use, and ensuring smooth operation in pumps and valves.

- If your primary focus is long-term reliability with minimal maintenance: PTFE's inherent resistance to degradation from chemicals, extreme temperatures, and UV light ensures the longest possible service life.

Ultimately, choosing PTFE is a strategic decision to engineer reliability directly into your most critical processes.

Summary Table:

| Property | Benefit for Chemical/Petrochemical Industries |

|---|---|

| Chemical Inertness | Resists virtually all aggressive acids, bases, and solvents, preventing degradation and leaks. |

| Wide Temperature Range | Performs reliably from cryogenic levels up to 260°C (500°F), ensuring stability during thermal cycling. |

| Low Coefficient of Friction | Reduces wear in pumps and valves, lowers energy consumption, and prevents stick-slip. |

| Long-Term Durability | High wear resistance and dimensional stability lead to extended service life and less maintenance. |

Engineer Uncompromising Reliability into Your Critical Processes with KINTEK

When failure is not an option, trust the material experts. KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the extreme demands of the chemical and petrochemical industries. Our capabilities range from custom prototypes to high-volume production, ensuring you get the exact PTFE solution your application requires for maximum safety, efficiency, and cost-effectiveness.

Contact KINTEK today to discuss your specific requirements and get a quote for seals built to perform in your harshest environments.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support