In shaft seal applications, the low friction coefficient of PTFE is its most significant performance advantage. This property directly translates into reduced wear on both the seal and the shaft, minimizes the energy required for rotation, and substantially extends the operational life of the entire assembly. The result is more efficient and reliable machinery with lower long-term maintenance costs.

The core benefit is simple: PTFE's low friction transforms a point of wear and energy loss into a source of efficiency. It's not just about a better seal; it's about improving the performance and longevity of the entire system it protects.

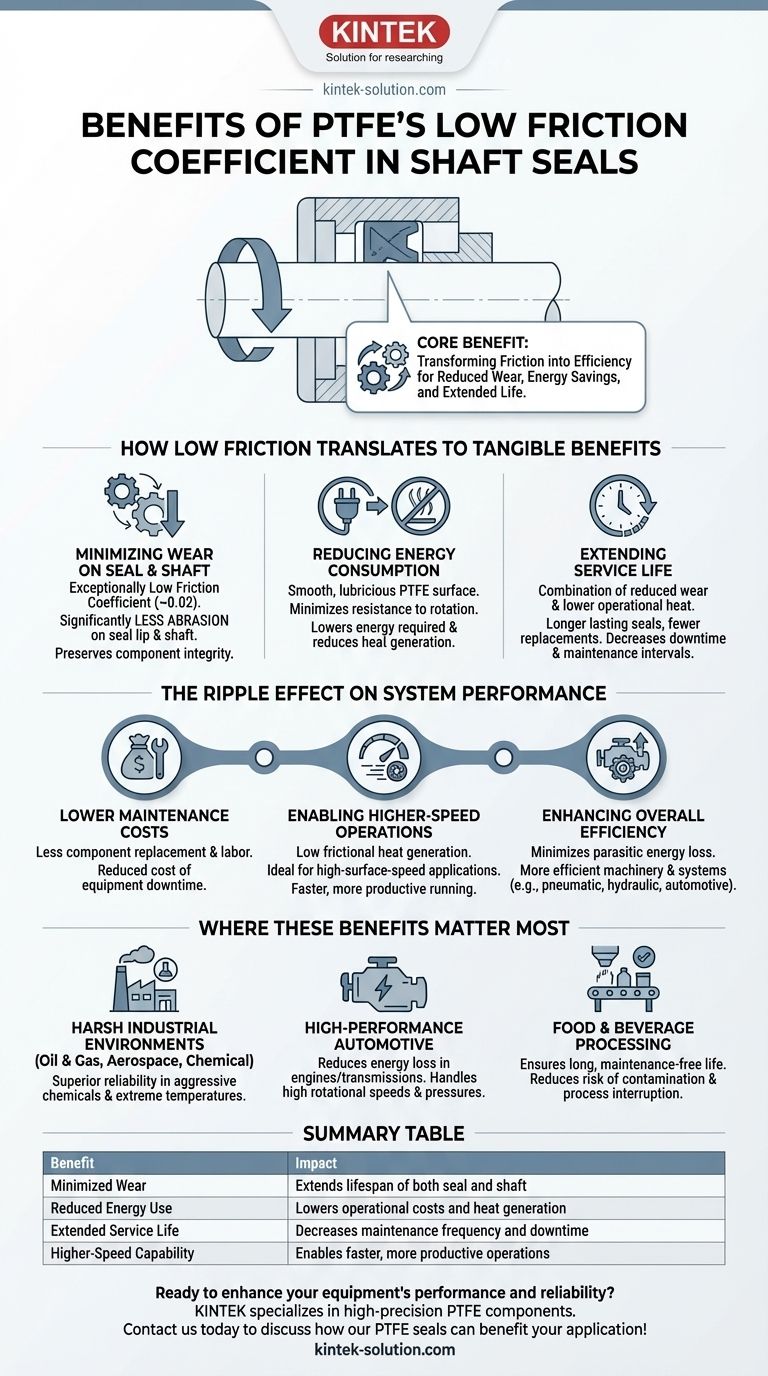

How Low Friction Translates to Tangible Benefits

The unique properties of Polytetrafluoroethylene (PTFE) create a cascade of positive effects that begin at the point of contact between the seal and the rotating shaft.

Minimizing Wear on Seal and Shaft

Friction is a physical force that abrades surfaces. By possessing an exceptionally low coefficient of friction (as low as 0.02), PTFE minimizes this abrasive action.

This means both the seal lip and the shaft surface experience significantly less wear and tear during operation, preserving the integrity of both components for longer.

Reducing Energy Consumption

Friction creates resistance, which machinery must overcome by using more energy. This wasted energy is often converted into heat, which can further degrade system components.

PTFE's smooth, lubricious surface allows the shaft to rotate with minimal resistance. This directly lowers the energy needed to run the equipment, improving overall efficiency.

Extending Service Life

The combination of reduced wear and lower operational heat means that PTFE seals simply last longer.

This extended lifespan reduces the frequency of replacements and maintenance intervals, leading to less downtime and greater productivity.

The Ripple Effect on System Performance

The advantages of low friction extend beyond the seal itself, influencing the operational capabilities and financial viability of the entire system.

Lowering Maintenance Costs

A longer-lasting seal directly translates to lower costs. This includes not only the price of the replacement part but also the labor and, most importantly, the cost of equipment downtime.

Enabling Higher-Speed Operations

A primary limitation in high-speed rotational applications is heat buildup caused by friction. Excessive heat can cause traditional seal materials to fail quickly.

Because PTFE generates very little frictional heat, it is the ideal choice for high-surface-speed applications, allowing equipment to run faster and more productively.

Enhancing Overall Efficiency

In systems like pneumatic and hydraulic machinery or automotive engines, every bit of lost energy reduces performance.

By minimizing this parasitic energy loss, PTFE seals contribute to more efficient machinery, which can even lead to benefits like reduced vehicle emissions.

Where These Benefits Matter Most

While broadly useful, the advantages of PTFE seals are most critical in demanding applications where other materials would quickly fail.

Harsh Industrial Environments

In industries like oil and gas, aerospace, and chemical processing, seals are exposed to aggressive chemicals and extreme temperatures. PTFE's chemical inertness combined with its low-friction durability makes it a superior choice for reliability.

High-Performance Automotive

Modern automotive systems demand efficiency and durability. PTFE seals are used to reduce energy loss in engines and transmissions, handle high rotational speeds, and withstand high-pressure conditions.

Food and Beverage Processing

In applications where contamination is a concern, the durability of PTFE seals ensures a long, maintenance-free life, reducing the risk of equipment failure and process interruption.

Making the Right Choice for Your Application

Selecting a PTFE seal is an investment in the long-term health and efficiency of your equipment.

- If your primary focus is reducing long-term operational costs: Choose PTFE to drastically cut expenses related to maintenance, component replacement, and energy consumption.

- If your primary focus is maximizing equipment performance: PTFE enables higher rotational speeds and greater system efficiency by minimizing frictional drag and heat buildup.

- If your primary focus is reliability in harsh environments: The combination of low friction, chemical resistance, and temperature tolerance makes PTFE the definitive choice for demanding applications.

Ultimately, investing in high-quality PTFE seals improves the lifespan and performance of your equipment by providing a superior, more durable sealing solution.

Summary Table:

| Benefit | Impact |

|---|---|

| Minimized Wear | Extends lifespan of both seal and shaft |

| Reduced Energy Use | Lowers operational costs and heat generation |

| Extended Service Life | Decreases maintenance frequency and downtime |

| Higher-Speed Capability | Enables faster, more productive operations |

Ready to enhance your equipment's performance and reliability?

KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that delivers superior efficiency, longevity, and cost savings.

Contact us today to discuss how our PTFE seals can benefit your specific application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers