At their core, Metal-Polymer Bronze Backed PTFE Plain Bearings are a composite structure designed to combine strength with a low-friction, self-lubricating surface. They consist of a rigid bronze backing that provides mechanical strength and a functional inner layer made of a Polytetrafluoroethylene (PTFE) based material that serves as the sliding surface.

The essential insight is that these bearings are not a single material but a layered system. This design strategically combines the structural integrity of metal with the exceptional low-friction properties of a polymer, creating a high-performance, maintenance-free component.

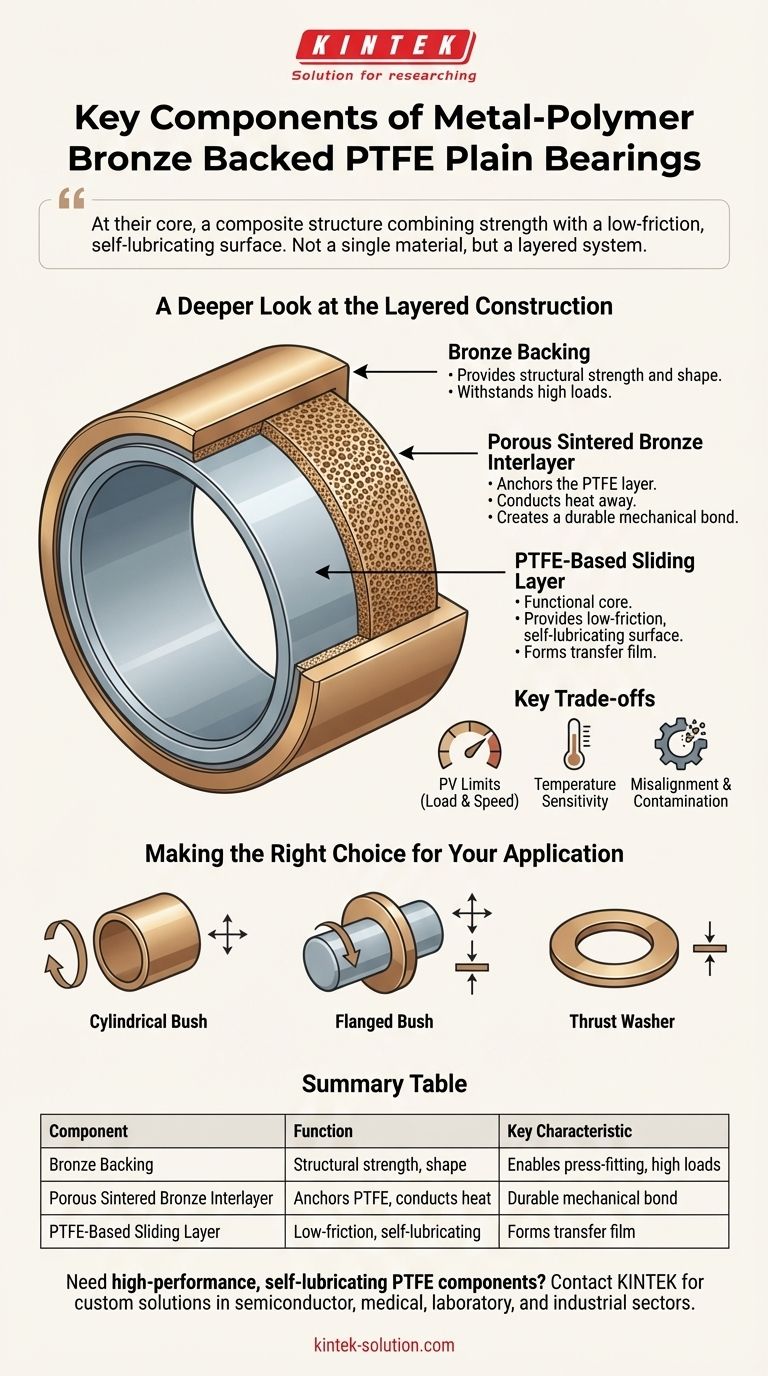

A Deeper Look at the Layered Construction

To understand how these bearings function, it's necessary to analyze the role of each distinct layer. The performance of the bearing is entirely dependent on these components working in concert.

The Bronze Backing

The outermost layer is a bronze backing. Its primary function is to provide the bearing's mechanical strength and structural shape, whether it's a cylindrical bush, a flanged bush, or a thrust washer.

This backing allows the bearing to be press-fit into a housing and enables it to withstand high loads and resist deformation during operation. Bronze is often chosen over steel for its superior corrosion resistance and thermal conductivity.

The Porous Sintered Bronze Interlayer

Bonded to the bronze backing is a crucial sintered porous bronze interlayer. This layer acts as a strong mechanical anchor for the soft PTFE sliding layer.

During manufacturing, the PTFE-based polymer mix is forced into the pores of this sintered bronze. This creates a durable lock, preventing the sliding layer from peeling away or shearing under heavy loads. It also helps conduct heat away from the sliding surface.

The PTFE-Based Sliding Layer

The final, innermost layer is the PTFE-based sliding surface. This is the functional core of the bearing, providing the low-friction and self-lubricating characteristics.

Initially, this layer is about 0.01 to 0.03 mm thick. As the bearing operates, a microscopic amount of this PTFE material transfers to the mating shaft, creating an optimal, low-friction "transfer film" on both surfaces. This process is what allows for smooth, stick-slip-free motion without external lubrication.

Understanding the Key Trade-offs

While highly effective, these bearings are not a universal solution. Understanding their limitations is critical for proper application and avoiding premature failure.

Load and Speed Capabilities

Metal-polymer bearings have specific pressure-velocity (PV) limits. Exceeding the recommended combination of load (pressure) and rotational speed will generate excessive heat, leading to accelerated wear and potential failure of the PTFE layer.

Temperature Sensitivity

The PTFE sliding layer has a defined operating temperature range. Excessively high temperatures can cause the polymer to soften and degrade, while extreme cold can make it brittle. The bronze backing helps dissipate heat, but the application's thermal environment must be considered.

Susceptibility to Misalignment and Contamination

The thin PTFE layer is susceptible to damage from shaft misalignment and abrasive contaminants. Hard particles like dirt or metal shavings can become embedded in the soft surface, scoring the shaft and destroying the bearing's low-friction properties.

Making the Right Choice for Your Application

The physical form of the bearing is determined entirely by the type of motion and load it must support.

- If your primary focus is supporting a rotating shaft: A standard cylindrical bush is the correct choice for handling radial loads.

- If you need to handle both radial and axial loads: A flanged bush provides a radial bearing surface and a thrust face to prevent axial movement.

- If you are managing purely axial (thrust) loads: A simple thrust washer is the most effective and direct solution.

Ultimately, this layered construction provides a robust, self-lubricating solution for a wide range of mechanical applications.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| Bronze Backing | Provides structural strength and shape | Enables press-fitting and withstands high loads |

| Porous Sintered Bronze Interlayer | Anchors the PTFE layer and conducts heat | Creates a durable mechanical bond |

| PTFE-Based Sliding Layer | Provides low-friction, self-lubricating surface | Forms a transfer film on the shaft for smooth motion |

Need high-performance, self-lubricating PTFE components for your application? KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, and bearings for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, our expertise ensures components that meet your exact load, speed, and environmental requirements. Contact our engineering team today to discuss your project and discover how we can enhance your design with reliable, maintenance-free PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs