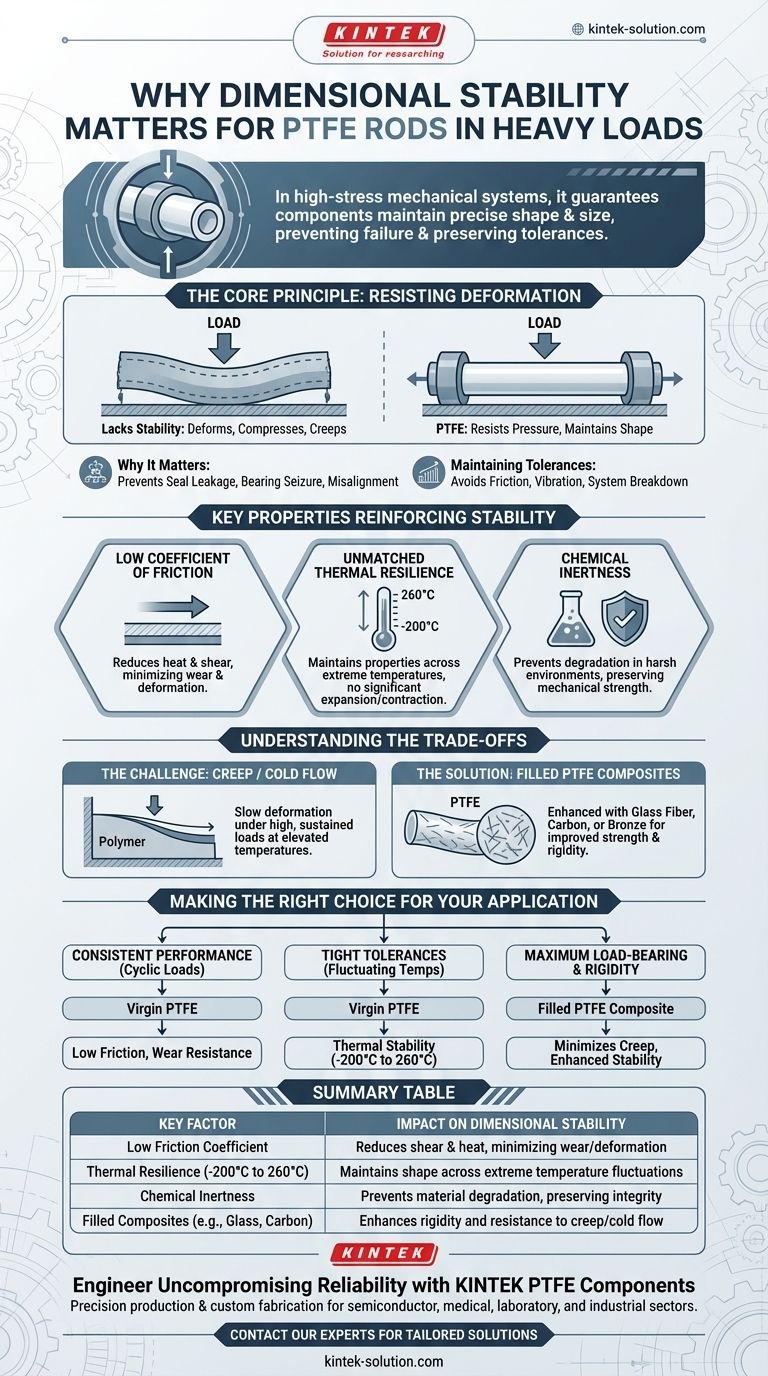

In high-stress mechanical systems, the dimensional stability of a Polytetrafluoroethylene (PTFE) rod is paramount because it guarantees the component will maintain its precise shape and size under heavy, continuous loads. This prevents mechanical failure, preserves critical operating tolerances, and ensures predictable, reliable performance throughout the equipment's service life.

The true value of PTFE's dimensional stability isn't just its resistance to physical force. It is the combination of its ability to withstand mechanical stress, extreme temperatures, and chemical attack that makes it a uniquely reliable material for critical, heavy-load applications.

The Core Principle: Resisting Deformation Under Load

In any mechanical assembly, every component has a specific size and shape it must maintain to function correctly. When a material lacks dimensional stability, it can deform, compress, or "creep" under stress, leading to system failure.

Why It Matters in Heavy-Load Scenarios

Under heavy loads, materials are subjected to immense and constant pressure. PTFE's molecular structure allows it to resist this pressure without permanently changing its shape. This prevents a cascade of potential failures, such as seal leakage, bearing seizure, or loss of alignment in moving parts.

Maintaining Critical Tolerances

Modern machinery, from aerospace actuators to industrial pistons, operates with extremely tight tolerances. Even a microscopic change in a component's dimensions can cause increased friction, vibration, or a complete system breakdown. PTFE's stability ensures it holds these precise dimensions, even when compressed or stressed.

Key Properties That Reinforce Stability

PTFE's dimensional stability is not an isolated feature; it is supported by a unique combination of other elite properties. Understanding how they work together reveals why this material is so effective.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any known solid. In a load-bearing application like a bushing or slide plate, this means less heat is generated and less shear force is exerted on the material as surfaces move against each other. This drastically reduces wear and the stresses that cause deformation.

Unmatched Thermal Resilience

A material's dimensions can change significantly with temperature. PTFE is remarkable for maintaining its physical properties across a vast temperature range, from cryogenic lows (-200°C) to high-heat environments (260°C). This thermal stability ensures a PTFE component in an engine or a chemical reactor will not expand or contract enough to compromise its function.

Chemical Inertness for Long-Term Integrity

Exposure to corrosive chemicals can weaken a material's structure, making it susceptible to failure under load. PTFE is virtually inert to all chemicals. This means it will not degrade in harsh industrial environments, preserving its mechanical strength and, by extension, its dimensional stability over time.

Understanding the Trade-offs

While exceptional, PTFE is not a perfect material for every scenario. True technical expertise requires acknowledging its limitations.

The Challenge of "Creep" or Cold Flow

Like all polymers, PTFE can exhibit a phenomenon known as creep or cold flow, where it will slowly deform under a very high, sustained load, particularly at elevated temperatures. This is a critical design consideration for engineers pushing the material to its absolute limits.

The Role of Fillers for Enhancement

To counteract creep and further enhance dimensional stability, PTFE is often blended with fillers. Adding materials like glass fiber, carbon, or bronze creates a composite with significantly improved mechanical strength, rigidity, and resistance to deformation, making it suitable for the most extreme load-bearing applications.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary operational goal.

- If your primary focus is consistent performance under cyclic loads: Rely on virgin PTFE's low friction and wear resistance, which prevent the kind of degradation that could alter component dimensions over time.

- If your primary focus is maintaining tight tolerances in fluctuating temperatures: Leverage PTFE's inherent thermal stability to ensure your component functions reliably from cryogenic pumps to high-temperature engine parts.

- If your primary focus is maximum load-bearing capacity and rigidity: Specify a filled PTFE composite (e.g., glass or carbon-filled) to minimize creep and achieve the highest possible level of dimensional stability.

By understanding these principles, you can engineer systems that are not just functional, but fundamentally reliable.

Summary Table:

| Key Factor | Impact on Dimensional Stability |

|---|---|

| Low Friction Coefficient | Reduces shear forces & heat generation, minimizing wear and deformation. |

| Thermal Resilience (-200°C to 260°C) | Maintains shape and size across extreme temperature fluctuations. |

| Chemical Inertness | Prevents material degradation, preserving structural integrity under load. |

| Filled Composites (e.g., Glass, Carbon) | Enhances rigidity and resistance to creep/cold flow for maximum loads. |

Engineer Uncompromising Reliability with KINTEK PTFE Components

When your heavy-load applications demand precision and durability, the right PTFE material makes all the difference. KINTEK specializes in manufacturing high-performance PTFE rods, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your components deliver the dimensional stability required for critical, high-stress environments.

Contact our experts today to discuss your specific requirements and receive a tailored solution that guarantees performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the available sizes and thicknesses for PTFE sheets? A Guide for Engineers & Designers

- How does the low friction property of PTFE bushes benefit applications? Extend Component Life and Reduce Maintenance

- Why are PTFE control valves important in chemical industries? Ensure Safety and Reliability in Harsh Environments

- What are the chemical resistance properties of expanded PTFE gaskets? A Guide to Universal Sealing Performance

- Why are quad rings preferred over O-rings in dynamic applications? Prevent Spiral Failure & Reduce Friction

- What are the key advantages of PTFE lined pipes? Superior Corrosion Resistance & Cost-Effective Flow

- What are the benefits of low friction in PTFE lined valves? Achieve Smoother Operation and Lower Costs

- What is a PTFE umbilical cord and how is it used in refineries? Ensure Accurate Process Control & Safety