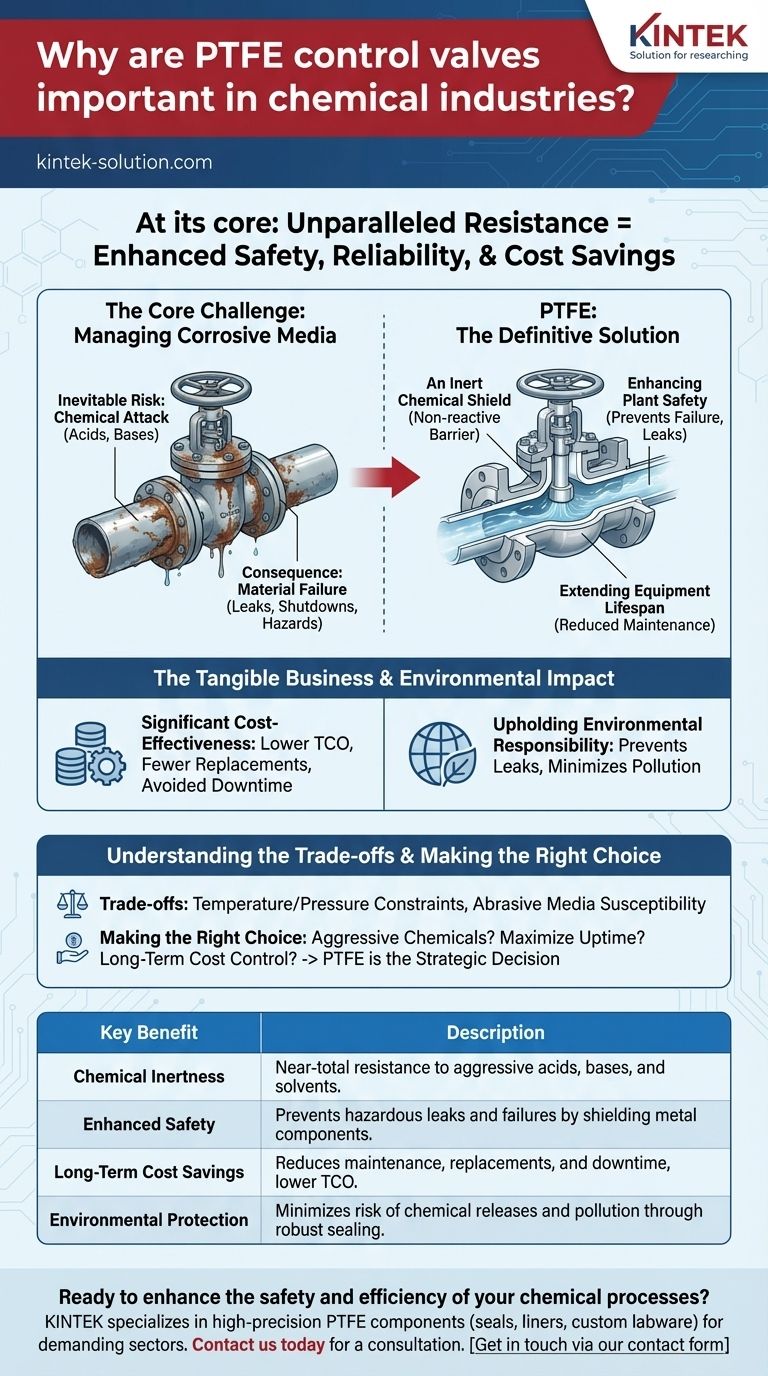

At its core, the importance of PTFE control valves in chemical industries stems from their unparalleled resistance to chemical corrosion, which directly translates into enhanced plant safety, operational reliability, and long-term cost savings. These valves create an inert barrier that protects critical equipment from aggressive media, preventing the material degradation that leads to costly failures and hazardous leaks.

The fundamental challenge in chemical processing is containing and controlling highly corrosive substances. PTFE-lined valves solve this by shielding the valve's structural metal from chemical attack, ensuring operational integrity where other materials would quickly fail.

The Core Challenge: Managing Corrosive Media

In any chemical, pharmaceutical, or fertilizer plant, the reliable transport and control of fluids is paramount. However, the very nature of these fluids presents a constant threat to the equipment designed to manage them.

The Inevitable Risk of Chemical Attack

Most standard metals, even specialized alloys, are susceptible to corrosion when exposed to strong acids, bases, and other reactive chemicals. This chemical attack is not a matter of if, but when.

The Consequence of Material Failure

Even minor corrosion can compromise a valve's integrity, leading to leaks, process contamination, or complete failure. Such events can cause unplanned shutdowns, catastrophic accidents, and significant environmental damage.

How PTFE Provides a Definitive Solution

Polytetrafluoroethylene (PTFE) is a fluoropolymer with unique properties that make it exceptionally well-suited for lining control valves and other fluid-handling components in harsh chemical environments.

An Inert Chemical Shield

The key advantage of PTFE is its chemical inertness. A PTFE lining acts as a seamless, non-reactive shield, completely isolating the valve's metal body from the corrosive process fluid.

This protective barrier ensures the valve's structural components are never exposed to harmful chemicals or rust, allowing the system to handle even the most aggressive substances without degradation.

Enhancing Plant Safety and Reliability

By preventing corrosion-induced material failure, PTFE valves are crucial for improving overall plant safety. They mitigate the risk of unforeseen accidents and leaks, contributing to a more stable and reliable operational environment.

Extending Equipment Lifespan

A direct result of this protection is a significantly longer equipment lifespan. Valves that would otherwise need frequent repair or replacement can operate for extended periods, reducing the need for costly maintenance cycles.

The Tangible Business and Environmental Impact

The decision to use PTFE-lined components goes beyond technical specifications; it has a direct impact on the bottom line and corporate responsibility.

Significant Cost-Effectiveness

While the initial investment may be higher, the total cost of ownership for PTFE valves is often lower. This is achieved through drastically reduced maintenance, fewer replacements, and the avoidance of expensive downtime associated with equipment failure.

Upholding Environmental Responsibility

The robust, non-corrosive nature of PTFE linings prevents the release of hazardous chemicals into the soil or waterways through leaks. Furthermore, their smooth, non-stick surface can reduce the need for lubricants or complex gaskets, minimizing potential sources of pollution.

Understanding the Trade-offs

While PTFE offers exceptional chemical resistance, it is not a universal solution. As a technical advisor, it's critical to acknowledge its operational boundaries to ensure proper application.

Temperature and Pressure Constraints

PTFE has specific temperature and pressure limits that are generally lower than those of solid metal valves. Exceeding these thresholds can lead to material deformation and failure.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. In applications with highly abrasive slurries or particulates, the lining can be susceptible to erosion and mechanical damage, potentially compromising its protective barrier.

Making the Right Choice for Your Application

Selecting the appropriate valve material is a critical engineering decision. The unique properties of PTFE make it the ideal choice for specific, high-stakes goals.

- If your primary focus is handling highly aggressive acids and bases: PTFE's near-total chemical inertness makes it the definitive choice for ensuring containment and preventing corrosion.

- If your primary focus is maximizing operational uptime and safety: The inherent reliability of PTFE-lined valves directly reduces the risk of failure-induced shutdowns and hazardous leaks.

- If your primary focus is long-term cost control: The extended lifespan and minimal maintenance needs of PTFE components deliver a superior return on investment compared to less-resistant materials.

Ultimately, specifying PTFE control valves is a strategic decision to insulate your operations from the inherent risks of chemical processing.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Provides near-total resistance to aggressive acids, bases, and solvents. |

| Enhanced Safety | Prevents hazardous leaks and failures by shielding metal components. |

| Long-Term Cost Savings | Reduces maintenance, replacements, and downtime, offering a lower total cost of ownership. |

| Environmental Protection | Minimizes risk of chemical releases and pollution through robust sealing. |

Ready to enhance the safety and efficiency of your chemical processes?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware, tailored for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you receive a solution that perfectly matches your application's requirements for chemical resistance and reliability.

Contact us today to discuss how our PTFE solutions can protect your equipment and optimize your operations. Get in touch via our contact form for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main components of a PTFE sliding pad? A Simple Two-Part System for Low-Friction Movement

- What are the typical tolerances for PTFE balls? Achieve Perfect Fit and Performance

- What are the media resistance properties of PTFE with fillers? Retains Chemical Inertness While Boosting Durability

- How does the construction of PTFE-lined plug valves provide chemical resistance? Achieve Unmatched Corrosion Protection

- What types of PTFE products are available for fluid handling solutions? Your Guide to High-Purity Components

- What advantages do PTFE expansion bellows offer over traditional alternatives? Achieve Unmatched Reliability in Demanding Environments

- When might additional lubrication be needed for PTFE applications? Understand the exceptions to the rule.

- What are the three types of springs used in PTFE seals? Optimize Your Seal Performance