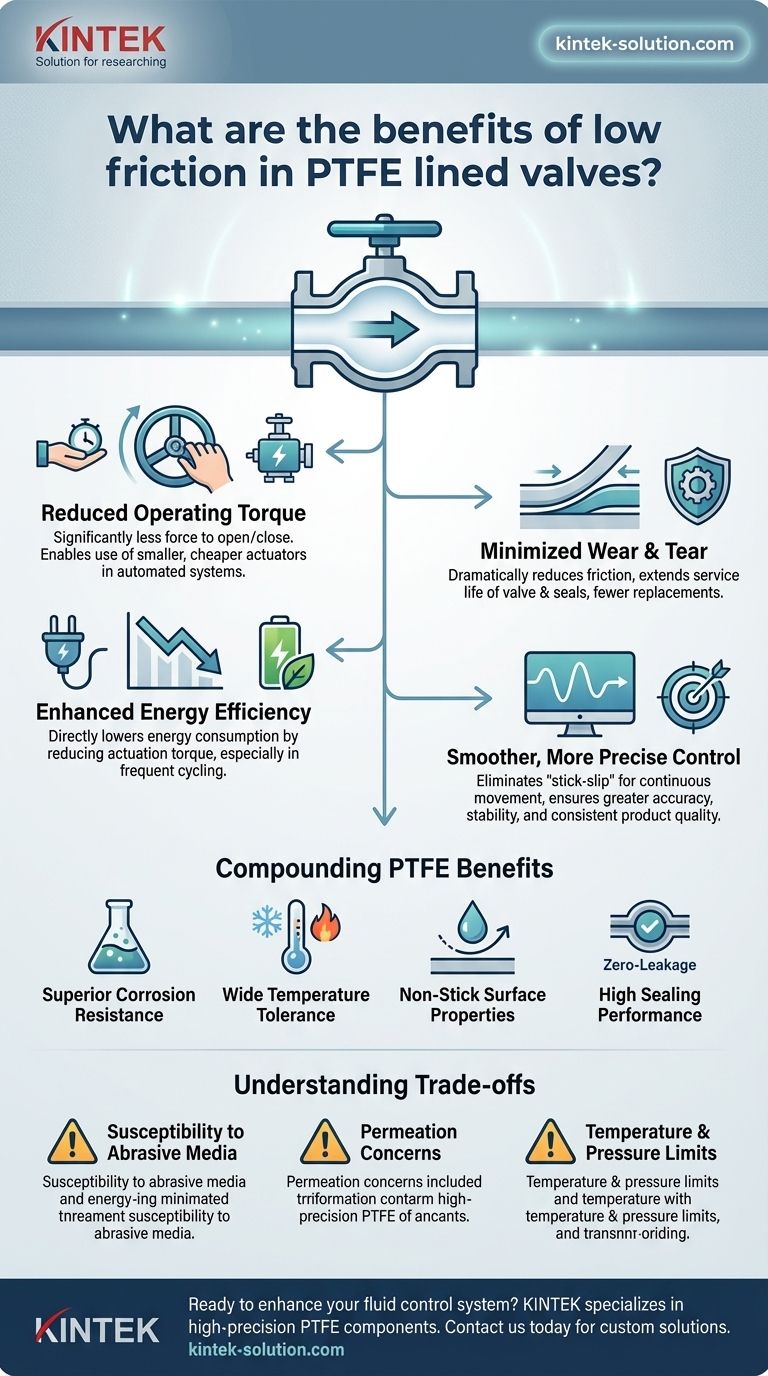

The primary benefits of low friction in PTFE lined valves are significantly reduced operating force, minimized wear and tear on valve components, and greater energy efficiency. This combination makes valve operation smoother, extends the equipment's service life, and lowers long-term operational costs, especially in automated systems.

The low friction of a PTFE lining is not just a minor feature; it is a core characteristic that creates a cascade of operational advantages, translating directly into lower energy consumption, longer valve life, and more precise process control.

The Tangible Impact of Low Friction

The uniquely low coefficient of friction in Polytetrafluoroethylene (PTFE) is a fundamental property that delivers several key performance benefits in industrial valve applications.

Reduced Operating Torque

Valves with PTFE linings require significantly less force to open and close. This property is known as low operating torque.

This makes manual operation easier for technicians and allows for the use of smaller, less expensive, and more energy-efficient actuators in automated systems.

Minimized Wear and Tear

Friction is the primary cause of wear on moving parts. The smooth, slick surface of PTFE dramatically reduces friction between the valve's disc or plug and its seat.

This reduction in wear extends the service life of the valve and its seals, such as O-rings, leading to fewer replacements and less maintenance-related downtime.

Enhanced Energy Efficiency

In any mechanical system, overcoming friction requires energy. By lowering the torque needed for actuation, PTFE lined valves directly reduce energy consumption.

This is especially impactful in processes with frequent valve cycling, contributing to more sustainable and cost-effective operations.

Smoother, More Precise Control

Low friction eliminates the "stick-slip" phenomenon, where a valve can jerk or move unevenly. This allows for smooth, continuous movement.

For processes that require precise flow regulation, this ensures greater accuracy and stability, guaranteeing maximum output and consistent product quality.

Beyond Friction: The Compounding Benefits of PTFE

While low friction is a critical advantage, it works in concert with other inherent properties of PTFE to create a highly reliable and versatile valve solution.

Superior Corrosion Resistance

PTFE is one of the most chemically inert materials used in industry. It can withstand strong acids, alkalis, and other corrosive media without degrading.

This makes PTFE lined valves an ideal choice for harsh chemical processing, pharmaceutical, and water treatment applications where other materials would fail.

Wide Temperature Tolerance

PTFE performs reliably across a very broad temperature range, typically from -196°C to over 200°C (-320°F to 392°F).

It remains soft and functional at cryogenic temperatures and maintains its integrity at high temperatures, offering exceptional versatility.

Non-Stick Surface Properties

The non-stick nature of PTFE, familiar from cookware, prevents process media from adhering to the valve's internal surfaces.

This reduces the potential for contamination, simplifies cleaning, and ensures consistent flow characteristics over time.

High Sealing Performance

The combination of a smooth surface and material flexibility allows PTFE lined valves to create a tight, reliable seal. This often results in zero-leakage performance, which is critical for safety and process efficiency.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to proper application.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. It is an excellent choice for clean liquids and gases but can be quickly damaged by slurries or fluids containing abrasive particles. These particles can score the lining, compromising the seal and negating its benefits.

Permeation Concerns

Certain highly aggressive chemicals and gases can, over time, permeate through the PTFE lining. This can lead to corrosion of the underlying valve body if not specified correctly for the service.

Temperature and Pressure Limits

While the temperature range is wide, PTFE does have an upper limit (typically 200-260°C). Above this point, the material can degrade. It also has pressure limitations that must be respected in system design.

Making the Right Choice for Your Application

Selecting a PTFE lined valve is a strategic decision that depends on your primary operational goal.

- If your primary focus is operational efficiency and automation: The low torque requirement allows for smaller actuators, reducing both initial capital outlay and long-term energy costs.

- If your primary focus is equipment longevity and low maintenance: The reduced wear on seals and components significantly extends the valve's service life and minimizes process downtime.

- If your primary focus is handling corrosive or sensitive media: PTFE's chemical inertness, combined with its smooth, non-stick surface, provides a reliable solution that protects both the valve and the process fluid.

Ultimately, leveraging the low-friction properties of PTFE lined valves is a direct path to a more reliable, efficient, and cost-effective fluid control system.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Reduced Operating Torque | Easier manual operation, smaller/cheaper actuators |

| Minimized Wear & Tear | Longer service life, less maintenance downtime |

| Enhanced Energy Efficiency | Lower energy consumption, especially with frequent cycling |

| Smoother, Precise Control | Eliminates stick-slip, ensures consistent flow and product quality |

Ready to enhance your fluid control system's reliability and efficiency?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Our expertise ensures your valves and systems benefit from the superior low-friction properties of PTFE, leading to reduced operational costs, extended equipment life, and precise process control—whether you're in the semiconductor, medical, laboratory, or industrial sector.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific needs. Contact us today to discuss how our PTFE solutions can solve your unique challenges and drive your operations forward.

Get in touch with our experts now!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining