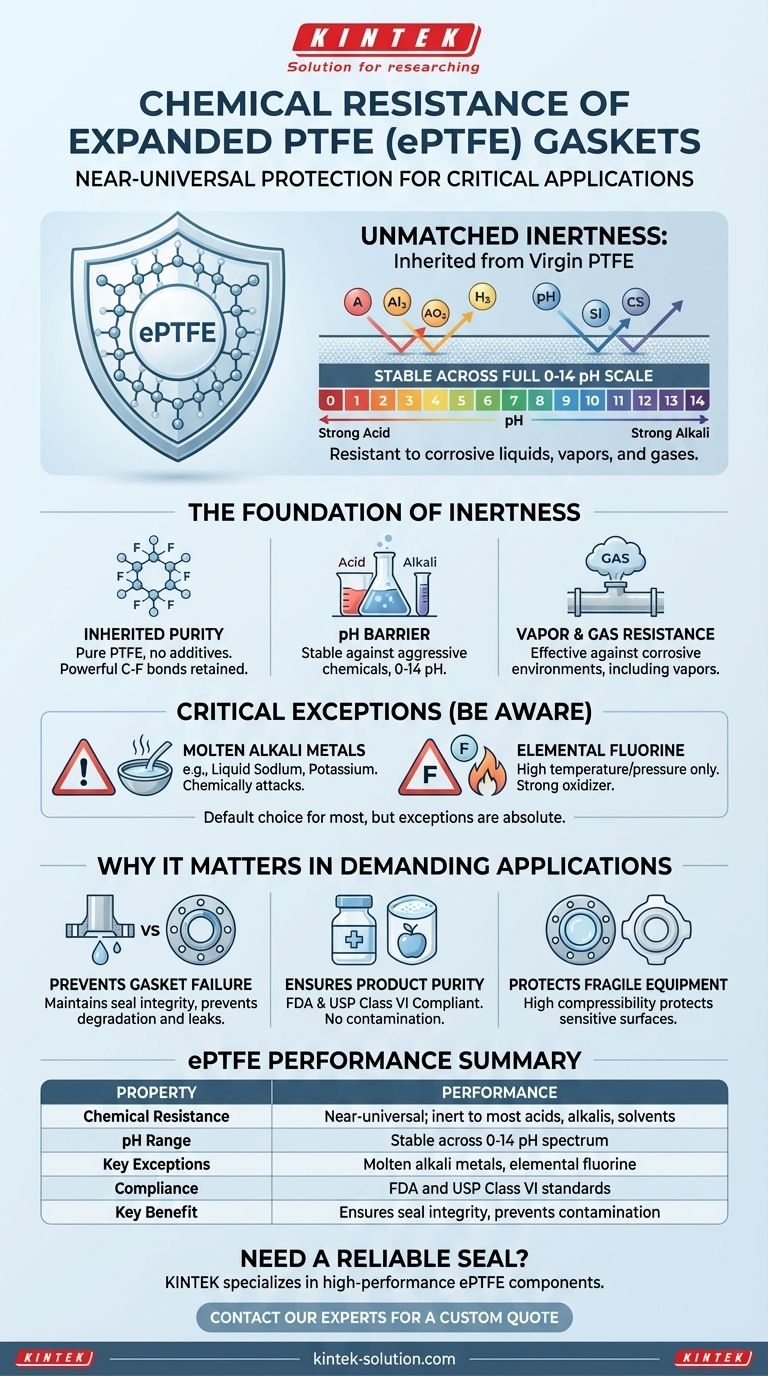

In short, expanded PTFE (ePTFE) gaskets offer near-universal chemical resistance. Because ePTFE is a physically altered form of pure Polytetrafluoroethylene (PTFE) with no additives, it inherits the exceptional chemical inertness of virgin PTFE. It is unaffected by the vast majority of corrosive liquids, vapors, and gases across the entire 0-14 pH scale.

The core principle to understand is that expanded PTFE is chemically inert to virtually all industrial chemicals. The only common exceptions are highly reactive substances like molten alkali metals and elemental fluorine, making it a default choice for the most demanding chemical sealing applications.

The Foundation of ePTFE's Chemical Inertness

The remarkable resistance of expanded PTFE is not a feature that is added; it is an intrinsic property of the base polymer. Understanding this foundation is key to trusting its performance in critical applications.

Inherited Purity from Virgin PTFE

Expanded PTFE is created by physically stretching pure PTFE, which creates a microporous, fibrous structure. No chemical reactions occur, and no binders or additives are introduced.

This means the final gasket material retains the same powerful carbon-fluorine bonds that make virgin PTFE one of the most non-reactive substances known.

A Barrier Across the Full pH Spectrum

The chemical stability of ePTFE is comprehensive. It remains completely stable when exposed to the most aggressive acids, alkalis (caustics), and solvents.

This allows it to reliably seal media anywhere on the pH scale, from 0 to 14, without degrading, swelling, or leaching.

Stability in Corrosive Vapors and Gases

The inertness of ePTFE is not limited to liquid contact. The material is equally resistant to chemical attack from corrosive vapors and gases, which is a critical factor in many chemical processing, refining, and manufacturing environments.

Understanding the Critical Exceptions

While its resistance is nearly universal, no material is infallible. Being aware of the specific, well-defined limitations of ePTFE is crucial for safe and effective material selection. Its failure points are few, but absolute.

Molten Alkali Metals

Expanded PTFE will be attacked by molten alkali metals. This category includes elements like liquid sodium and potassium.

These substances are reactive enough to disrupt the strong fluorine-carbon bonds that give PTFE its stability. However, these are highly specialized conditions and not present in most industrial processes.

Elemental Fluorine

The other key exception is elemental fluorine, particularly at high temperatures and pressures. It is important to distinguish this from fluoride compounds (like hydrofluoric acid), to which ePTFE is completely resistant.

Elemental fluorine is one of the most powerful oxidizing agents known and is one of the few chemicals that can chemically attack the fully fluorinated polymer.

Why This Matters in Demanding Applications

The chemical resistance of a gasket is not an abstract property; it has direct consequences for safety, reliability, and product quality.

Preventing Gasket Degradation and Failure

The primary role of a gasket is to maintain a seal. A gasket that is chemically attacked will soften, swell, or dissolve, leading to a loss of sealing stress and, ultimately, a catastrophic leak. The inertness of ePTFE ensures a stable and long-lasting seal.

Ensuring Product Purity

In industries like pharmaceuticals, food and beverage, and semiconductors, process purity is paramount. Expanded PTFE gaskets meet stringent FDA and USP Class VI standards because they do not react with or contaminate the process media.

Protecting Fragile Equipment

Many applications involving aggressive chemicals also use fragile flange materials like glass-lined steel or ceramics. Expanded PTFE's combination of extreme chemical resistance and high compressibility allows it to create a tight seal on these surfaces without causing damage.

Making the Right Choice for Your Application

Selecting the correct gasket material requires matching its properties to the specific demands of the service.

- If your primary focus is handling aggressive acids, caustics, or solvents: Expanded PTFE is an ideal choice, providing a reliable seal across the entire 0-14 pH range.

- If your process involves molten alkali metals or elemental fluorine: You must specify an alternative material, as ePTFE will be chemically attacked and fail in these services.

- If process purity and FDA compliance are your main concerns: Expanded PTFE is a proven, safe material that will not contaminate the process media.

- If you are sealing a fragile or imperfect flange in a corrosive environment: The excellent compressibility and chemical inertness of ePTFE make it one of the best available options.

By understanding both its unmatched capabilities and its precise limitations, you can confidently specify expanded PTFE for nearly any chemical sealing challenge.

Summary Table:

| Property | Expanded PTFE (ePTFE) Performance |

|---|---|

| Chemical Resistance | Near-universal; inert to most acids, alkalis, solvents |

| pH Range | Stable across the entire 0-14 pH spectrum |

| Key Exceptions | Molten alkali metals, elemental fluorine |

| Compliance | Meets FDA and USP Class VI standards for purity |

| Key Benefit | Ensures seal integrity and prevents product contamination |

Need a reliable seal for aggressive chemicals?

KINTEK specializes in manufacturing high-performance expanded PTFE components, including gaskets, seals, and custom labware. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a chemically inert sealing solution that protects your equipment and guarantees process purity.

Contact our experts today to discuss your specific chemical sealing challenge and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers