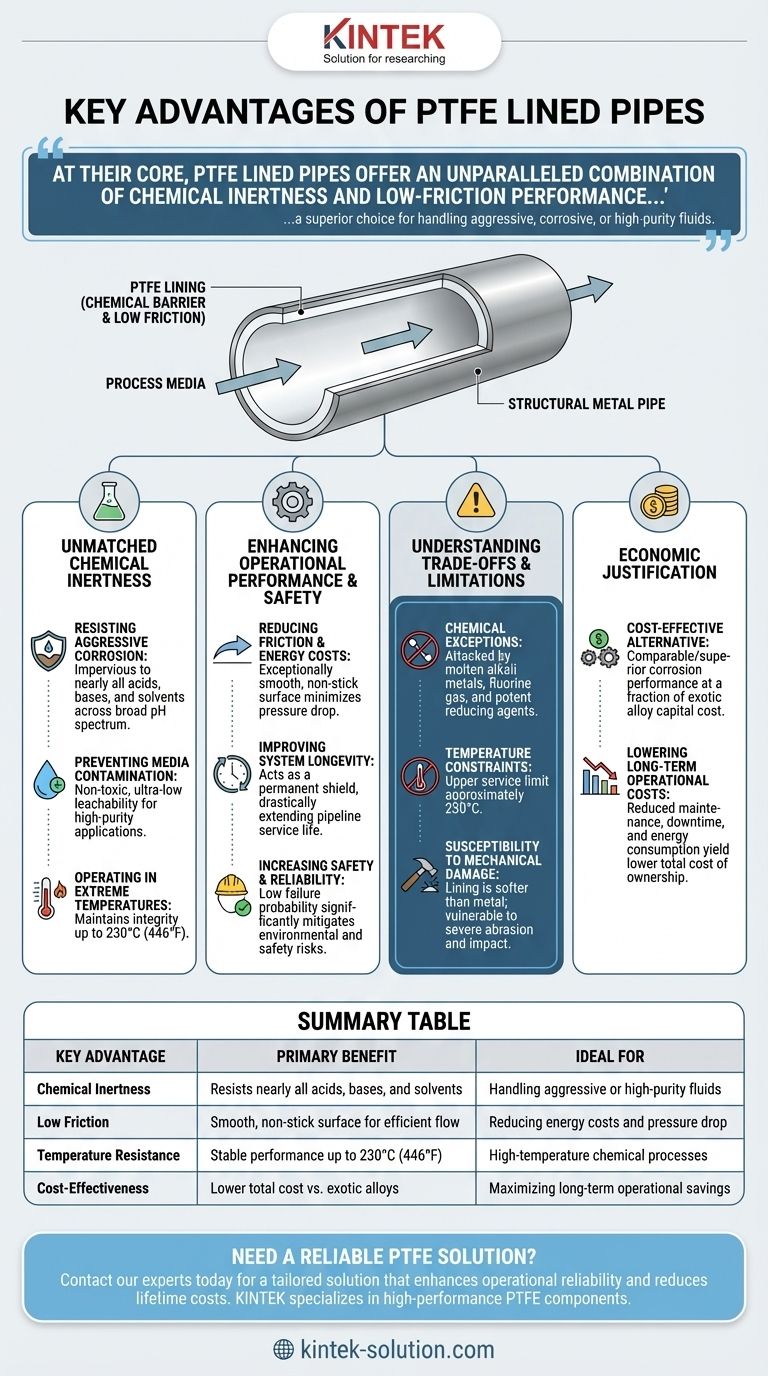

At their core, PTFE lined pipes offer an unparalleled combination of chemical inertness and low-friction performance, making them a superior choice for handling aggressive, corrosive, or high-purity fluids. This lining acts as a protective barrier, isolating the process media from the structural pipe material, which prevents corrosion, reduces contamination, and ensures smooth, efficient flow across a wide range of temperatures.

The primary advantage of a PTFE lined pipe is not just its resistance to corrosion, but its ability to deliver long-term operational certainty. It is a strategic investment to mitigate the high costs and risks associated with system failure, downtime, and media contamination in demanding industrial environments.

The Core Benefit: Unmatched Chemical Inertness

The defining characteristic of Polytetrafluoroethylene (PTFE) is its near-total immunity to chemical attack. This property is the foundation for its most significant advantages in industrial piping.

Resisting Aggressive Corrosion

A PTFE lining is impervious to nearly all industrial chemicals, acids, and bases across a broad pH spectrum. This allows a standard carbon or stainless steel pipe to safely transport highly corrosive fluids that would otherwise require expensive and difficult-to-source exotic metal alloys.

Preventing Media Contamination

For high-purity applications, such as in the pharmaceutical, food and beverage, or semiconductor industries, maintaining the integrity of the process fluid is paramount. PTFE is non-toxic, features extremely low leachability, and will not contaminate the media it carries.

Operating in Extreme Temperatures

PTFE maintains its integrity and chemical resistance at high temperatures, often rated for continuous service up to 230°C (446°F). This stability makes it suitable for a wide range of chemical processes that run hot.

Enhancing Operational Performance and Safety

Beyond chemical resistance, the physical properties of PTFE lining directly contribute to a more efficient, reliable, and safer piping system.

Reducing Friction and Energy Costs

PTFE has one of the lowest coefficients of friction of any solid material, creating an exceptionally smooth, non-stick surface. This minimizes pressure drop, ensures consistent flow, and can reduce the energy consumption 외부f pumps needed to move the fluid.

Improving System Longevity

The lining acts as a permanent shield for the outer pipe. By preventing corrosion, it drastically extends the service life of the entire pipeline, reducing the frequency and cost of replacement.

Increasing Safety and Reliability

Pipeline failure in a corrosive service can be catastrophic, leading to environmental damage, safety hazards for personnel, and costly production halts. PTFE's low failure probability સફેદand effective sealing capabilities significantly mitigate these risks.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined pipe is not a universal solution. An objective evaluation requires understanding its limitations.

Chemical Exceptions

PTFE is incredibly inert, but it can be attacked by a few rare substances. These include molten alkali metals (like sodium), fluorine gas, and other potent reducing agents at extreme conditions.

Temperature Constraints

While its high-temperature performance is excellent, PTFE does have an upper service limit. Applications exceeding approximately 230°C will require different materials, such as glass-lined or exotic alloy piping.

Susceptibility to Mechanical Damage

The PTFE liner, while durable, is softer than metal. It can be susceptible to damage from severe abrasion by hard-particle slurries or by mechanical impact. Care must be taken during installation and operation to protect the integrity of the liner.

The Economic Justification

Choosing a piping material is a financial decision as much as it is a technical one. PTFE lined systems offer a compelling economic case in the right context.

A Cost-Effective Alternative to Exotic Alloys

For services requiring high corrosion resistance, the primary alternatives are often pipes made entirely of expensive alloys like Hastelloy, Monel, or Titanium. PTFE lined carbon steel pipe provides comparable or superior corrosion performance at a fraction of the capital cost.

Lowering Long-Term Operational Costs

The true value is realized over the system's lifespan. By eliminating corrosion, reducing maintenance, preventing downtime, and lowering pumping energy, PTFE lined pipes offer a significantly lower total cost of ownership.

Making the Right Choice for Your Application

Selecting the optimal piping solution depends entirely on your primary objective.

- If your primary focus is maximum corrosion resistance: PTFE lined pipe is the default choice for handling complex, multi-component, or highly aggressive chemical mixtures.

- If your primary focus is high-purity processes: The non-leaching and non-toxic nature of PTFE makes it ideal for applications in the pharmaceutical, food, or semiconductor industries.

- If your primary focus is long-term cost reduction: PTFE lined pipe is a strategic choice to avoid the high capital cost of exotic alloys while minimizing lifetime maintenance and aporisk.

By understanding these capabilities, you can confidently specify a piping system that delivers both elite performance and long-term economic value.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents | Handling aggressive or high-purity fluids |

| Low Friction | Smooth, non-stick surface for efficient flow | Reducing energy costs and pressure drop |

| Temperature Resistance | Stable performance up to 230°C (446°F) | High-temperature chemical processes |

| Cost-Effectiveness | Lower total cost vs. exotic alloys | Maximizing long-term operational savings |

Need a reliable PTFE solution for your critical piping system?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-lined pipes, seals, and liners. Our precision production ensures your systems in the semiconductor, medical, laboratory, and industrial sectors achieve maximum corrosion resistance, purity, and flow efficiency—from prototype to high-volume orders.

Let's discuss your specific requirements. Contact our experts today for a tailored solution that enhances your operational reliability and reduces lifetime costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do PTFE gaskets perform in extreme temperatures? From -200°C to +260°C

- How does PTFE's low thermal conductivity impact machining? Master Heat Management for Precision Parts

- In which industries are PTFE washers commonly used? Essential for Aerospace, Medical, and Chemical Processing

- What toolpath strategies benefit thin-wall PTFE machining? Master Precision with Helical Paths and Low-Stress Techniques

- What is the difference between Teflon valves and PTFE lined valves? Choose the Right Valve for Your System

- What industries benefit from the use of custom Teflon rotary shaft seals? Enhance Reliability in Demanding Applications

- Why is PTFE considered important in RF PCB applications? Ensure Superior Signal Integrity

- What are PTFE O-rings and their properties? A Guide to High-Performance Sealing