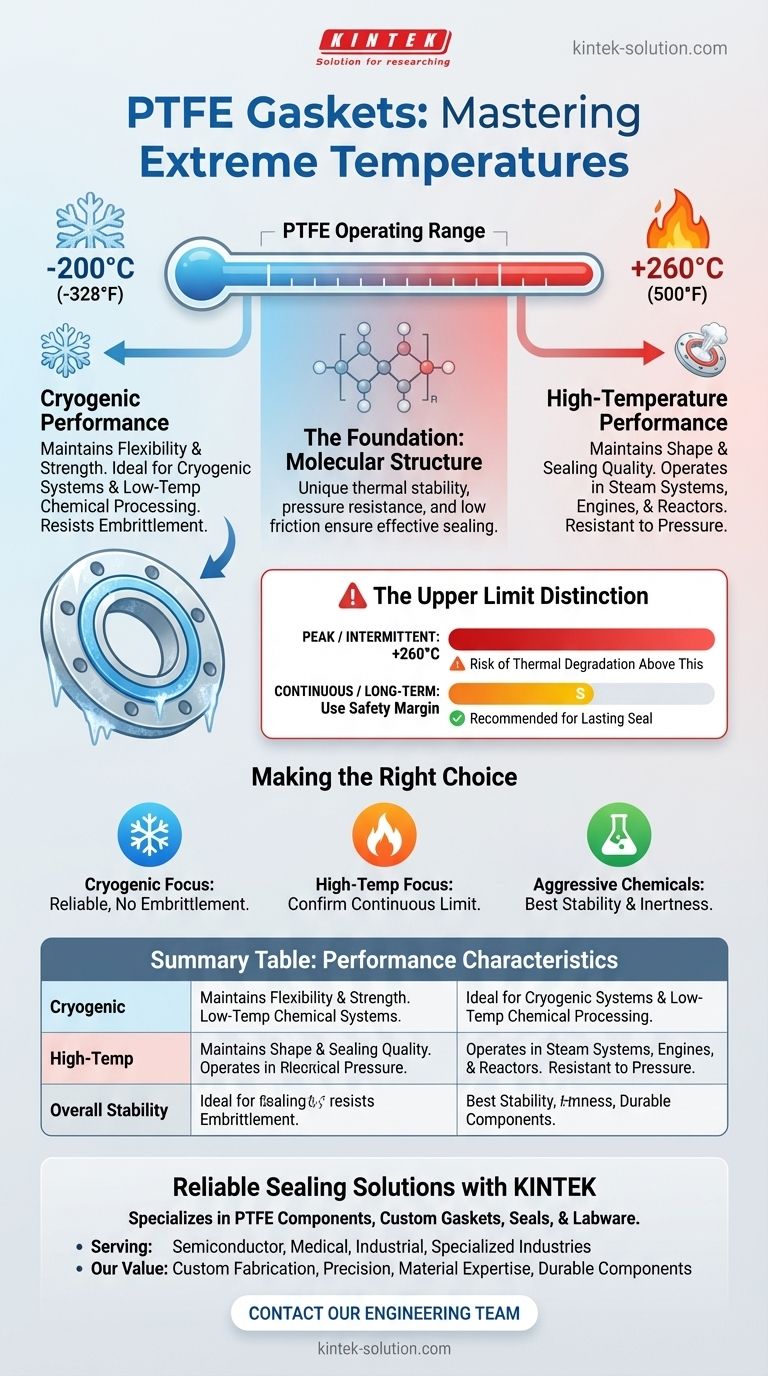

In short, Polytetrafluoroethylene (PTFE) gaskets offer exceptional performance across a vast temperature range. They reliably maintain their sealing properties in conditions from deep cryogenic freezes up to high-temperature industrial processes, specifically from -200°C (-328°F) to +260°C (500°F). This remarkable stability makes them a default choice for many demanding applications.

The core takeaway is that while PTFE has one of the widest operating temperature ranges of any sealing material, its reliability at the upper limit is not absolute. Understanding the difference between peak and continuous temperature exposure is critical to preventing material degradation and ensuring a lasting seal.

The Foundation: Why PTFE Excels in Temperature Extremes

The unique molecular structure of PTFE is the source of its thermal stability. This allows it to function effectively where many other materials would fail by becoming brittle or melting.

Performance in the Cryogenic Range

At the low end of its spectrum, PTFE maintains its integrity in temperatures as cold as -200°C (-328°F).

Unlike many plastics that become brittle and crack in extreme cold, PTFE retains sufficient flexibility and strength, making it an ideal choice for cryogenic systems and chemical processing at low temperatures.

Performance in the High-Temperature Range

PTFE gaskets can operate continuously at temperatures up to +260°C (500°F).

They maintain their shape and sealing quality in demanding environments such as steam systems, high-powered engines, and chemical reactors. This durability ensures long-term performance without frequent replacement.

Inherent Material Stability

Beyond just temperature, PTFE's performance is supported by its other properties.

It is highly resistant to pressure and has an extremely low coefficient of friction. This ensures a low leakage rate and the ability to maintain seal integrity with minimal surface compression, even as temperatures fluctuate.

Understanding the Trade-offs: The Upper Temperature Limit

While the +260°C rating is impressive, it is not without its limitations. Misunderstanding this upper limit is a common source of gasket failure.

The Risk of Thermal Degradation

If exposed to prolonged temperatures at or above its peak rating, PTFE can begin to break down.

This degradation can cause the material to lose its sealing properties, potentially leading to leaks and system failure. For this reason, caution is advised in applications involving large, constantly heated areas.

Differentiating Continuous vs. Peak Temperature

The +260°C figure should be considered a peak, or intermittent, temperature limit.

For applications requiring continuous, long-term service at high heat, a more conservative temperature ceiling is recommended to build in a safety margin and prevent material breakdown over time.

Making the Right Choice for Your Application

Selecting the right gasket requires matching the material's capabilities to the system's operational demands.

- If your primary focus is cryogenic or low-temperature sealing: PTFE is an exceptionally reliable and proven choice due to its ability to avoid low-temperature embrittlement.

- If your primary focus is high-temperature sealing (approaching +260°C): PTFE is a strong candidate, but you must confirm that the continuous operating temperature allows for a safe margin below its peak rating.

- If your primary focus is handling aggressive chemicals across a wide temperature range: PTFE's combination of thermal stability and near-total chemical inertness makes it one of the best materials available.

By respecting its operational limits, you can confidently deploy PTFE to achieve a reliable, long-lasting seal in the most extreme environments.

Summary Table:

| Temperature Range | Performance Characteristics | Key Considerations |

|---|---|---|

| Cryogenic: -200°C (-328°F) | Maintains flexibility and strength; resists embrittlement | Ideal for cryogenic systems and low-temperature chemical processing |

| High-Temp: Up to +260°C (500°F) | Maintains shape and sealing quality; resistant to pressure and friction | +260°C is a peak/intermittent limit; continuous use requires safety margin |

| Overall Stability | Exceptional thermal and chemical stability across entire range | Widest operating temperature range of common sealing materials |

Need Reliable Sealing Solutions for Extreme Temperatures?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gaskets, seals, liners, and labware. Our precision production ensures reliable performance from cryogenic applications to high-temperature industrial processes.

We serve:

- Semiconductor and electronics manufacturers

- Medical and laboratory equipment providers

- Industrial and chemical processing plants

- Specialized industries requiring custom fabrication

Our value to you:

- Custom fabrication from prototypes to high-volume orders

- Precision manufacturing for consistent quality and performance

- Expertise in material selection for your specific temperature requirements

- Durable components that withstand extreme environments

Let us help you achieve a reliable, long-lasting seal for your most demanding applications. Contact our engineering team today to discuss your specific requirements and get a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers