A wide range of demanding industries rely on custom Teflon rotary shaft seals, including aerospace, oil and gas, chemical processing, food and beverage, and medical equipment manufacturing. These specialized components are chosen for their unique ability to perform reliably in environments with extreme temperatures, aggressive chemicals, high pressures, and high rotational speeds where standard seals would fail.

The core benefit of custom Teflon seals isn't just the material itself, but the ability to precisely engineer a solution for a specific challenge. This shifts the conversation from finding a "good enough" part to creating the optimal component that maximizes equipment life and minimizes costly downtime.

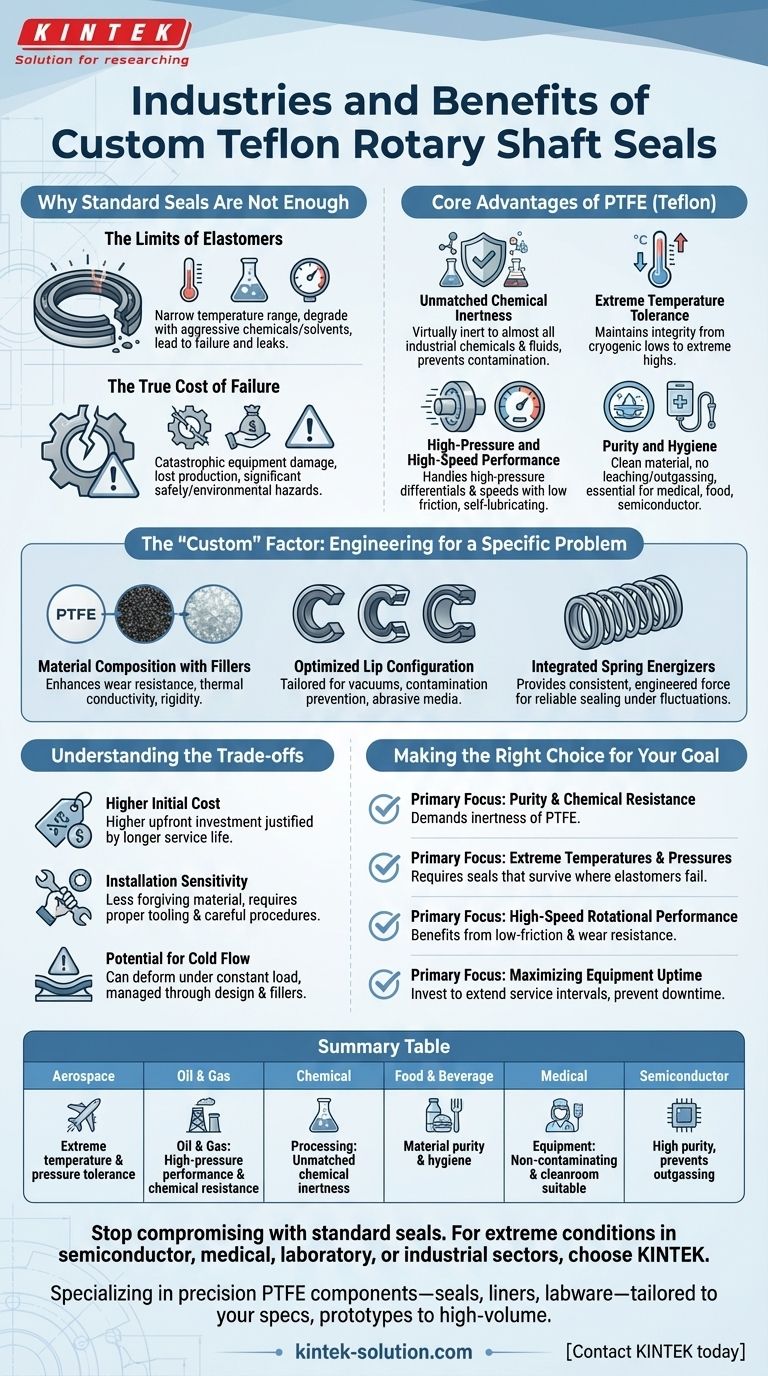

Why Standard Seals Are Not Enough

Traditional rotary seals are often made from elastomeric materials like nitrile or Viton rubber. While effective in many general applications, they have inherent limitations that make them unsuitable for more demanding operational contexts.

The Limits of Elastomers

Elastomers have a relatively narrow operating temperature range and can degrade quickly when exposed to aggressive chemicals or solvents. This breakdown leads to seal failure, leaks, and potential contamination.

The True Cost of Failure

A failed seal is more than an inconvenience. In critical industries, it can mean catastrophic equipment damage, lost production batches costing millions, and significant safety or environmental hazards.

The Core Advantages of PTFE (Teflon)

Custom seals made from Polytetrafluoroethylene (PTFE), the material commonly known as Teflon, directly address the shortcomings of traditional materials. Their value is rooted in a unique combination of properties.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and fluids. This makes it the default choice for equipment in chemical processing, pharmaceuticals, and food production, where contamination is not an option.

Extreme Temperature Tolerance

PTFE seals maintain their integrity and performance across a vast temperature spectrum, from cryogenic lows to extreme highs, far exceeding the capabilities of rubber-based seals.

High-Pressure and High-Speed Performance

These seals are engineered to handle high-pressure differentials and high-speed rotating shafts without significant wear. Their low-friction, self-lubricating nature generates less heat, extending both the seal and equipment lifespan.

Purity and Hygiene

In medical, food and dairy, and semiconductor applications, material purity is critical. PTFE is a clean material that doesn't leach or outgas, ensuring it won't contaminate the process media.

The "Custom" Factor: Engineering for a Specific Problem

The ability to customize a PTFE seal is what elevates it from a component to a true engineering solution. Customization allows designers to overcome specific operational challenges.

Material Composition with Fillers

Base PTFE can be blended with fillers like carbon, graphite, glass, or stainless steel. These fillers enhance specific properties, such as increasing wear resistance, improving thermal conductivity, or boosting rigidity to handle higher pressures.

Optimized Lip Configuration

The design of the seal lip—the part that makes contact with the shaft—can be tailored. Different lip shapes are used to optimize sealing for vacuums, prevent external contamination, or handle abrasive media.

Integrated Spring Energizers

A metal spring energizer is often integrated into the seal jacket. This spring provides a consistent, engineered force against the shaft, ensuring a reliable seal even with temperature fluctuations, pressure changes, or minor shaft imperfections.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal replacement for all other seal types. Understanding their limitations is key to using them correctly.

Higher Initial Cost

A custom-engineered PTFE seal has a higher upfront cost than a standard, off-the-shelf elastomer seal. This cost is justified by significantly longer service life and the prevention of costly failures.

Installation Sensitivity

PTFE is a less forgiving material than rubber. It is more rigid and has less elasticity, meaning proper tooling and careful procedures are required during installation to avoid damaging the seal lip.

Potential for Cold Flow

Under a constant load, PTFE can exhibit "creep" or "cold flow," slowly deforming over time. This is a well-understood property that is managed through proper seal design and the use of fillers to improve dimensional stability.

Making the Right Choice for Your Goal

The decision to use a custom Teflon seal is driven by the operational demands and the consequences of failure.

- If your primary focus is purity and chemical resistance: Your application in food, medical, or semiconductor manufacturing demands the inertness that only PTFE can provide.

- If your primary focus is extreme temperatures and pressures: Aerospace, oil and gas, and chemical processing applications require seals that can survive where elastomers cannot.

- If your primary focus is high-speed rotational performance: Equipment like compressors, pumps, and motorsports powertrains benefit from the low-friction and wear-resistant properties of custom PTFE seals.

- If your primary focus is maximizing equipment uptime: Any manufacturing or industrial process with critical rotating equipment can justify the investment to extend service intervals and prevent costly downtime.

Ultimately, choosing a custom Teflon rotary shaft seal is an engineering decision to invest in reliability where performance is non-negotiable.

Summary Table:

| Industry | Key Benefit of Custom PTFE Seal |

|---|---|

| Aerospace | Extreme temperature & pressure tolerance |

| Oil & Gas | High-pressure performance & chemical resistance |

| Chemical Processing | Unmatched chemical inertness |

| Food & Beverage | Material purity & hygiene |

| Medical Equipment | Non-contaminating & cleanroom suitable |

| Semiconductor | High purity, prevents outgassing |

Stop compromising with standard seals. If your operations in the semiconductor, medical, laboratory, or industrial sectors demand reliability under extreme temperatures, aggressive chemicals, or high pressures, a custom-engineered PTFE solution from KINTEK is the answer.

We specialize in manufacturing precision PTFE components—including seals, liners, and labware—tailored to your exact specifications, from prototypes to high-volume orders. Let us help you maximize equipment uptime and eliminate costly failures.

Contact KINTEK today to discuss your custom sealing challenge.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers