For engineers and designers, PTFE O-rings are high-performance seals chosen for their extraordinary resistance to chemicals and extreme temperatures. Composed of Polytetrafluoroethylene, a fluoropolymer of carbon and fluorine, they provide sealing solutions where conventional rubber-based materials would quickly fail. Their defining characteristics are near-universal chemical inertness, a vast operating temperature range, and an extremely low coefficient of friction.

The central takeaway is that PTFE O-rings are a specialist solution, not a general-purpose one. They offer unparalleled performance in harsh environments but trade the flexible, resilient sealing capability of traditional elastomers for high hardness and a tendency to deform under load.

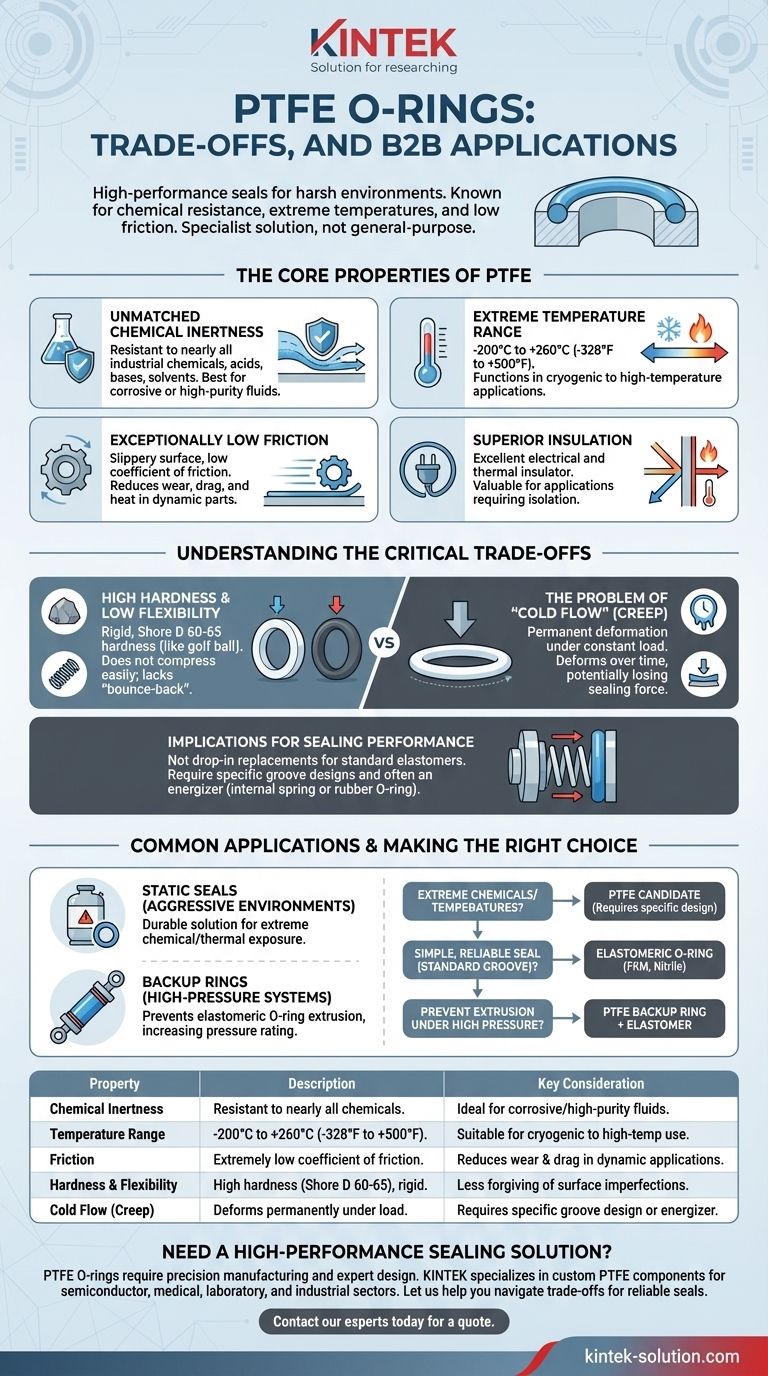

The Core Properties of PTFE

The unique molecular structure of Polytetrafluoroethylene gives these seals a set of properties that make them indispensable for demanding applications.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents. Its only known vulnerabilities are to molten alkali metals and highly reactive fluorinating agents.

This makes PTFE O-rings the default choice for systems handling corrosive or high-purity fluids where contamination or seal degradation is not an option.

Extreme Temperature Range

These seals can function effectively across an exceptionally wide thermal window, typically cited from -200°C to +260°C (-328°F to +500°F).

This allows them to be used in everything from cryogenic applications to high-temperature processing equipment without losing their integrity.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a distinctively slippery surface.

This property is highly valuable in dynamic applications where it can reduce wear, drag, and heat generation between moving parts.

Superior Insulation

As a material, PTFE is an excellent electrical and thermal insulator. While not always the primary reason for its selection as a seal, this property adds value in applications where electrical isolation or thermal breaks are required.

Understanding the Critical Trade-offs

The same properties that make PTFE a superior material in some contexts create significant limitations. Understanding these trade-offs is essential for successful implementation.

High Hardness and Low Flexibility

Unlike rubber O-rings, which are soft and pliable, PTFE O-rings are quite rigid. They typically have a hardness of 60-65 on the Shore D scale, which is comparable to a hard plastic like a golf ball.

This rigidity means they do not compress easily to fill imperfections in sealing surfaces. They lack the "bounce-back" or memory of an elastomer, making them less forgiving of hardware variations.

The Problem of "Cold Flow"

A critical characteristic of PTFE is creep, or "cold flow." When subjected to a constant compressive load, the material will slowly and permanently deform.

This is the opposite of a rubber O-ring, which stores energy when compressed and pushes back to maintain a seal. A PTFE O-ring under pressure will simply deform, potentially leading to a loss of sealing force over time.

Implications for Sealing Performance

Because of their hardness and tendency to creep, solid PTFE O-rings cannot be used as direct drop-in replacements for standard elastomeric O-rings in most static or dynamic applications.

They require specifically designed grooves and often need an energizer (like an internal spring or a separate rubber O-ring) to provide the constant force needed for a reliable seal.

Common Applications for PTFE Seals

Given their specific profile of strengths and weaknesses, PTFE seals excel in several key roles.

Static Seals in Aggressive Environments

In applications where the seal is stationary and the primary challenge is extreme chemical or thermal exposure, a properly installed PTFE O-ring can provide a durable, long-lasting solution.

Backup Rings for Elastomeric O-rings

One of the most common uses for PTFE is as a backup ring. In high-pressure systems, a hard PTFE ring is placed behind a traditional rubber O-ring.

The PTFE ring is strong enough to prevent the softer rubber O-ring from being extruded into the clearance gap, dramatically increasing the pressure rating of the entire sealing system.

Making the Right Choice for Your Application

Selecting the correct sealing material requires matching its properties to the primary demands of the system.

- If your primary focus is sealing against extreme chemicals or temperatures: PTFE is a leading candidate, but you must account for its mechanical limitations in your hardware design.

- If your primary focus is a simple, reliable seal in a standard groove: A standard elastomeric O-ring (like FKM/Viton™ or Nitrile) is almost always a better and more forgiving choice.

- If you need to prevent O-ring extrusion under high pressure: Using a PTFE backup ring in conjunction with a traditional elastomeric O-ring is a proven and highly effective strategy.

Ultimately, understanding these fundamental trade-offs is the key to leveraging PTFE's unique strengths without succumbing to its weaknesses.

Summary Table:

| Property | Description | Key Consideration |

|---|---|---|

| Chemical Inertness | Resistant to nearly all industrial chemicals. | Ideal for corrosive or high-purity fluids. |

| Temperature Range | Operates from -200°C to +260°C (-328°F to +500°F). | Suitable for cryogenic to high-temperature use. |

| Friction | Extremely low coefficient of friction. | Reduces wear and drag in dynamic applications. |

| Hardness & Flexibility | High hardness (Shore D 60-65), rigid. | Less forgiving of surface imperfections than rubber. |

| Cold Flow (Creep) | Deforms permanently under constant load. | Requires specific groove design or an energizer. |

Need a high-performance sealing solution for a demanding environment?

PTFE O-rings are a specialist solution, and their successful implementation requires precision manufacturing and expert design consideration. KINTEK specializes in the custom fabrication of high-quality PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

We can help you navigate the trade-offs of PTFE to leverage its strengths in your application. From prototypes to high-volume orders, our focus on precision ensures a reliable seal for your most critical systems.

Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers