In short, a PTFE umbilical cord is a specialized assembly of multiple, long Polytetrafluoroethylene (PTFE) tubes bundled together within a protective PVC coating. In a refinery, its critical function is to transport highly corrosive or reactive gas samples from a process reaction chamber to a laboratory for analysis, ensuring the sample's chemical composition remains completely unchanged during transit.

The core challenge in refinery process control is getting an accurate snapshot of a chemical reaction. A PTFE umbilical cord solves this by creating an inert, protected pathway that guarantees the gas sample arriving at the lab is identical to the one that left the reactor.

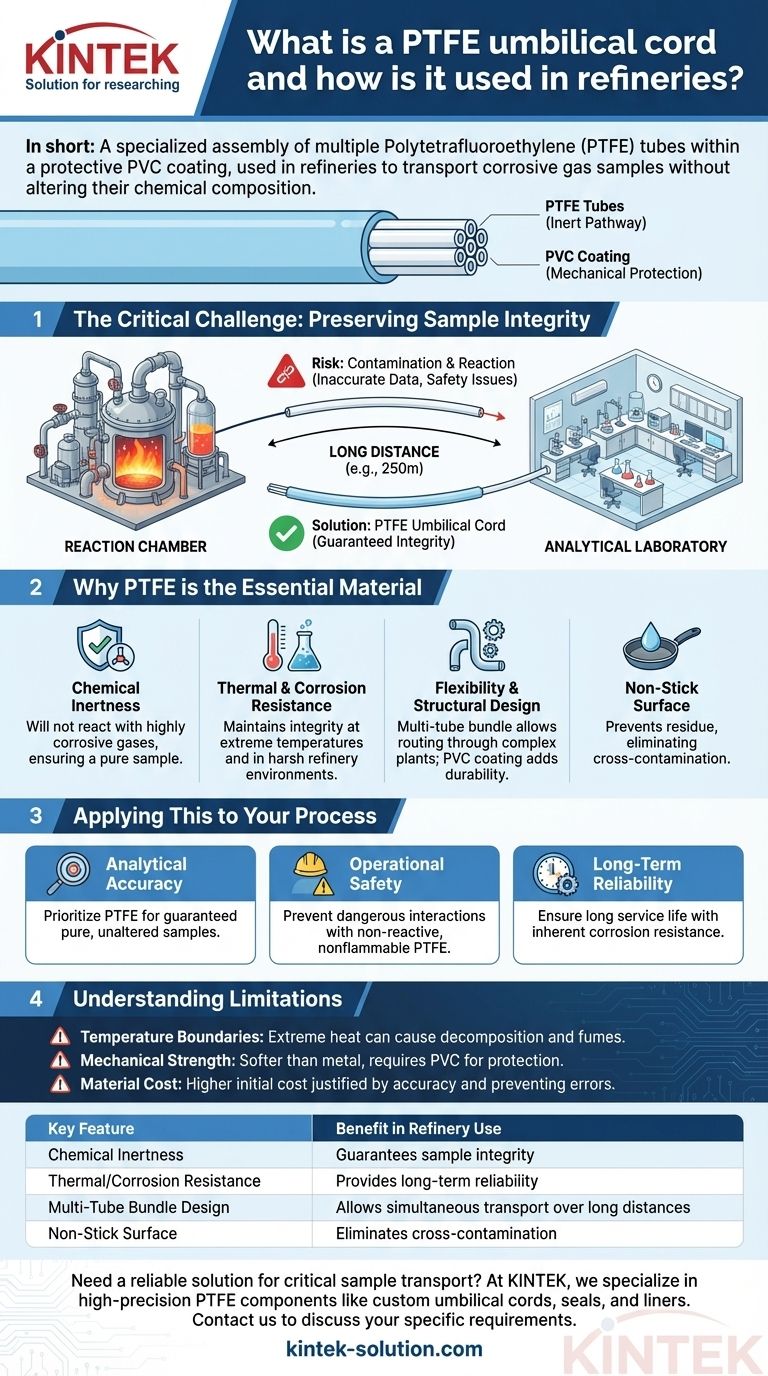

The Critical Challenge: Preserving Sample Integrity

From the Reaction Chamber to the Lab

Refineries operate on precise chemical reactions. To ensure efficiency and safety, operators must constantly analyze the gases produced in reaction chambers.

These samples must travel, often over long distances like 250 meters, from the harsh environment of the reactor to the sterile, controlled environment of an analytical laboratory.

The Risk of Contamination and Reaction

The primary risk during this transit is that the transport tube itself will react with the gas sample. Even a minor reaction can alter the chemical makeup of the gas, leading to flawed analysis.

Inaccurate data can lead to incorrect process adjustments, resulting in reduced yield, off-spec product, or even dangerous operational conditions. The transport medium must be completely neutral.

Why PTFE is the Essential Material

Polytetrafluoroethylene (PTFE) is not just a convenient choice for this application; its unique combination of properties makes it one of the only materials suitable for the task.

Unmatched Chemical Inertness

The most critical property of PTFE is that it is chemically inert. It will not react with the vast majority of industrial chemicals, including the highly corrosive and reactive gases common in refineries.

This non-reactivity ensures that the gas sample remains pure and unaltered, providing the lab with a true and accurate representation of the process.

Superior Thermal and Corrosion Resistance

Refinery environments involve extreme temperatures and corrosive substances. PTFE is highly resistant to both.

It maintains its integrity at high temperatures and does not degrade when exposed to corrosive agents, ensuring the long-term reliability of the umbilical cord.

Flexibility and Structural Design

The umbilical cord structure, consisting of 12-15 individual tubes, requires a flexible material. PTFE's natural flexibility allows the assembly to be routed through the complex infrastructure of a plant.

The bundle is then coated in PVC, which adds a layer of mechanical protection and durability against the industrial environment.

Non-Stick and Non-Contaminating

PTFE is famous for its non-stick surface. This property prevents any residue from previous samples from adhering to the tube walls, eliminating the risk of cross-contamination between tests.

Understanding the Limitations

While PTFE is an exceptional material, it's important to understand its context and limitations for any engineering application.

Temperature Boundaries

PTFE is nontoxic and stable under normal operating conditions. However, like any polymer, it has an upper temperature limit. If exposed to extreme temperatures beyond its specification, it can begin to decompose and release harmful fumes.

Mechanical Strength

PTFE is a relatively soft material with a low coefficient of friction. While excellent for non-stick properties, it means it is not as resistant to abrasion or cutting as a metal. This is why the PVC coating on the umbilical cord is essential for mechanical protection.

Material Cost

As a high-performance fluoropolymer, PTFE is generally more expensive than common plastics or standard metal tubing. However, this cost is easily justified by the critical need for sample accuracy and the prevention of costly process errors.

Applying This to Your Process

Choosing the right material is about aligning its properties with your primary objective. The PTFE umbilical cord is a purpose-built solution for a specific and critical industrial need.

- If your primary focus is analytical accuracy: PTFE's absolute chemical inertness is the most important feature, as it guarantees a pure, unaltered sample reaches the lab.

- If your primary focus is operational safety: The non-reactive and nonflammable properties of PTFE prevent dangerous interactions between the sample gas and the transport line.

- If your primary focus is long-term reliability: The material's inherent corrosion resistance ensures a long service life, even in the harsh, chemically aggressive environment of a refinery.

Ultimately, selecting a PTFE umbilical cord is a strategic decision to prioritize data integrity and safety in critical process control.

Summary Table:

| Key Feature | Benefit in Refinery Use |

|---|---|

| Chemical Inertness | Guarantees sample integrity by preventing reactions with corrosive gases. |

| Thermal/Corrosion Resistance | Provides long-term reliability in harsh refinery environments. |

| Multi-Tube Bundle Design | Allows simultaneous transport of multiple samples over long distances (e.g., 250m). |

| Non-Stick Surface | Eliminates cross-contamination between samples for accurate analysis. |

Need a reliable solution for critical sample transport?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom umbilical cords, seals, and liners. Our expertise ensures your refinery or industrial process benefits from unmatched sample integrity, operational safety, and long-term reliability.

We offer custom fabrication from prototypes to high-volume orders, tailored to the demanding needs of the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss your specific requirements and ensure your process control is built on a foundation of accuracy.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications