In short, Teflon bushings are exceptionally well-suited for food processing applications because their core properties directly address the industry's most critical requirements: food safety and operational hygiene. The material is fundamentally non-toxic, chemically inert, and features a non-stick surface that resists both contamination and the aggressive cleaning agents used to ensure sanitary conditions.

The suitability of Teflon (PTFE) in food processing goes beyond simple compliance. Its unique combination of chemical inertness, non-stick properties, and thermal stability solves the dual challenge of preventing product contamination while maximizing the operational efficiency and cleanability of the machinery itself.

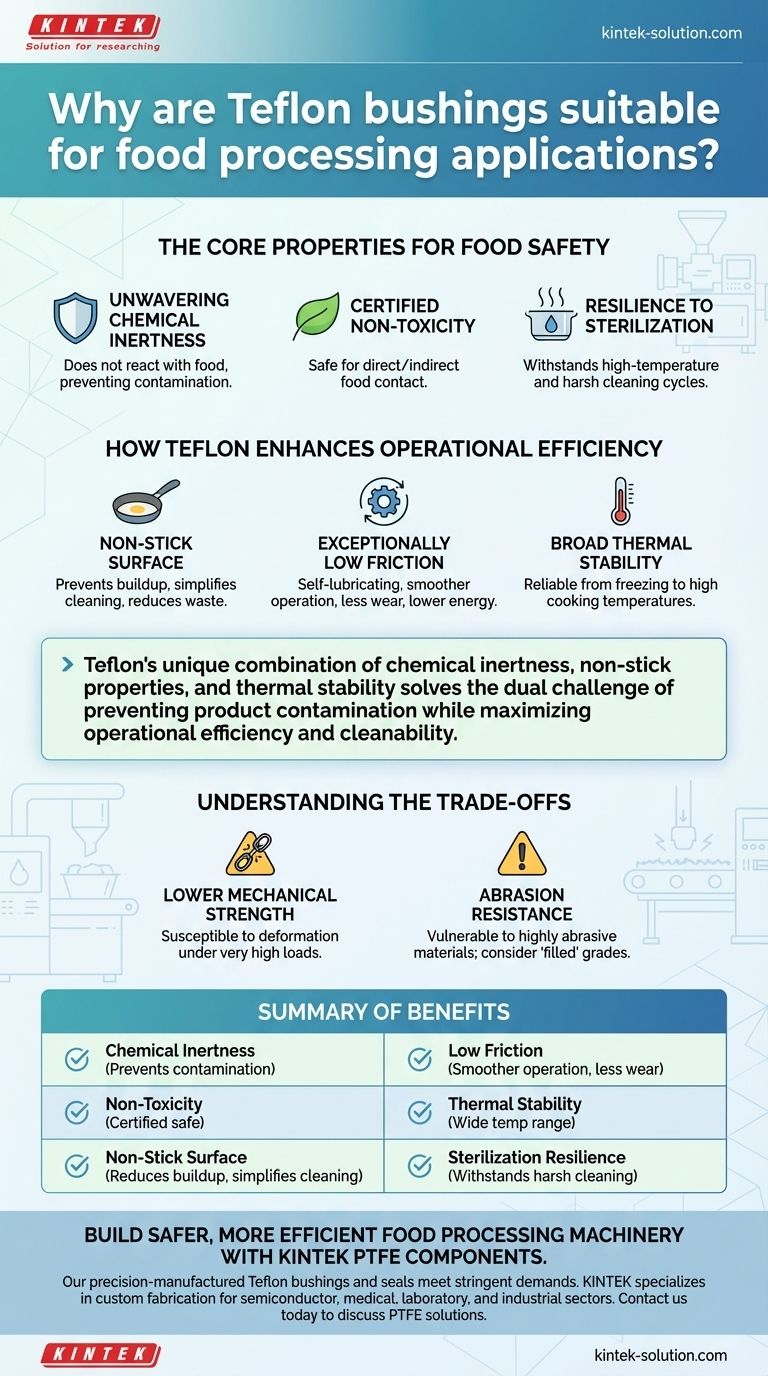

The Core Properties That Ensure Food Safety

To understand why Teflon is a trusted material in this sector, we must examine the specific properties that align with the stringent demands of producing food for consumption.

Unwavering Chemical Inertness

Teflon, or Polytetrafluoroethylene (PTFE), is one of the most chemically inert polymers known. It does not react with acids, bases, or the complex organic compounds found in food products.

This inertness is critical because it ensures the bushing material will not degrade, corrode, or leach any of its components into the food stream, preventing contamination and preserving product purity.

Certified Non-Toxicity

Food-grade Teflon is inherently non-toxic and biocompatible. This means it is safe for direct and indirect contact with food products intended for human consumption.

This characteristic is a fundamental prerequisite for any material used in food processing equipment and is a primary reason for Teflon's widespread adoption.

Resilience to Sterilization

Food processing equipment must undergo frequent and rigorous cleaning and sterilization cycles, which often involve high temperatures, steam, or harsh chemical sanitizers.

Teflon is resistant to these sterilization processes. It maintains its structural integrity and performance characteristics, ensuring a long service life and consistent safety without breaking down.

How Teflon Enhances Operational Efficiency

Beyond safety and compliance, Teflon bushings provide tangible benefits that improve the day-to-day operation of food processing machinery.

The Advantage of a Non-Stick Surface

Teflon's famously low coefficient of friction creates a non-stick surface. In a food processing context, this property is invaluable for preventing food products from adhering to machinery parts.

This reduces product buildup, minimizes waste, and dramatically simplifies cleaning. Equipment can be cleaned more quickly and effectively, reducing downtime and preventing the growth of bacteria in hard-to-clean areas.

Exceptionally Low Friction

The self-lubricating nature of Teflon bushings reduces friction between moving parts. This leads to smoother, more reliable machinery operation with less wear and tear.

Lower wear means fewer particulates from the bushing material are generated, further reducing the risk of contamination. It also contributes to lower energy consumption and extended maintenance intervals.

Broad Thermal Stability

Teflon performs reliably across an extremely wide range of temperatures. This makes it suitable for equipment used in all stages of food processing, from flash-freezing and cold storage to baking and high-temperature cooking.

This thermal stability ensures consistent performance and material integrity, regardless of the specific thermal demands of the application.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. It's important to recognize its limitations to ensure it is specified correctly.

Lower Mechanical Strength

Compared to metal bushings, standard PTFE can be susceptible to deformation or "creep" under very high mechanical loads. This must be a key consideration during the design phase.

Abrasion Resistance

While its low-friction surface is a major benefit, standard Teflon can be vulnerable to wear from highly abrasive food materials, such as grains, sugar crystals, or certain powders.

For these demanding applications, "filled" grades of Teflon—which incorporate additives like glass, carbon, or stainless steel—are often used to significantly improve wear resistance and mechanical strength.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your primary goal.

- If your primary focus is compliance and hygiene: Teflon's non-toxic, inert, and non-stick properties make it a premier choice for ensuring food safety and ease of sanitation.

- If your primary focus is operational uptime: The material's resistance to harsh cleaning cycles and its self-lubricating nature reduce downtime for both cleaning and maintenance.

- If your application involves high loads or abrasive media: You must consider engineered or filled PTFE grades designed to provide the necessary mechanical strength and durability.

By understanding how Teflon's distinct characteristics align with industry demands, you can confidently specify it to build safer and more efficient food processing systems.

Summary Table:

| Property | Benefit in Food Processing |

|---|---|

| Chemical Inertness | Prevents contamination; won't react with food or cleaning agents. |

| Non-Toxicity | Certified safe for direct and indirect food contact. |

| Non-Stick Surface | Reduces product buildup, minimizes waste, and simplifies cleaning. |

| Low Friction | Self-lubricating for smoother operation, less wear, and lower energy use. |

| Thermal Stability | Performs reliably across a wide temperature range (freezing to cooking). |

| Sterilization Resilience | Withstands high-temperature steam and harsh chemical cleaning cycles. |

Build safer, more efficient food processing machinery with KINTEK PTFE components.

Our precision-manufactured Teflon bushings, seals, and custom labware are engineered to meet the stringent demands of the food industry. We ensure your equipment achieves the highest standards of hygiene and operational uptime.

KINTEK specializes in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors, delivering everything from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your application's food safety and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the electrical insulation properties of PTFE caps? Superior Dielectric Performance for Demanding Applications

- What are some emerging trends in PTFE gasket technology? Innovations in Materials and Manufacturing

- How does the cost of PTFE PCBs compare to FR4 PCBs? A Guide to High-Frequency Material Selection

- How does CNC machining benefit PTFE part production? Achieve Precision, Consistency & Complex Designs

- What industries commonly use PTFE gaskets and why? Solve Demanding Sealing Challenges

- What are the two primary grades of PTFE? Virgin vs. Mechanical for Your Application

- What is a potential drawback of using stainless steel filler in PTFE? Balancing Durability and System Wear

- What are some common applications of Teflon machining? Unlock Performance in Harsh Environments