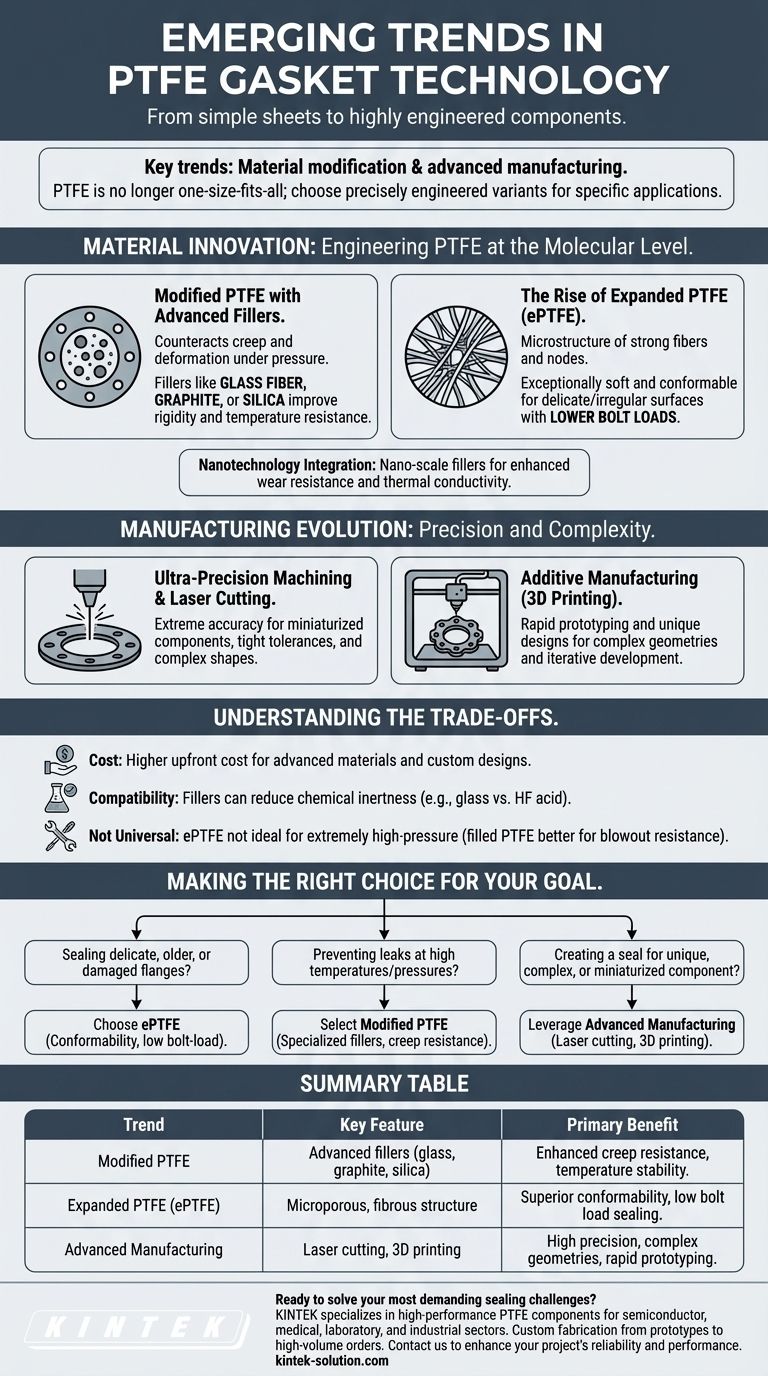

In short, the key emerging trends in PTFE gasket technology are material modification and advanced manufacturing. Gaskets are evolving from simple PTFE sheets to highly engineered components using specialized fillers, expanded microstructures like ePTFE, and precision fabrication methods like laser cutting and 3D printing to solve specific, demanding sealing challenges.

The central takeaway is that PTFE is no longer a one-size-fits-all material. The future of reliable sealing lies in selecting a precisely engineered PTFE variant—whether modified, expanded, or custom-fabricated—that directly targets the unique pressures, temperatures, and surface conditions of your application.

Material Innovation: Engineering PTFE at the Molecular Level

The most significant advancements are happening within the material itself. Raw PTFE has well-known limitations, such as creep (cold flow) under load, which new technologies directly address.

Modified PTFE with Advanced Fillers

Standard PTFE can deform under pressure, leading to leaks. To counteract this, manufacturers now use specialized fillers to create composite materials.

Fillers like glass fiber, graphite, or silica are blended into the PTFE matrix. This dramatically improves the gasket's rigidity, temperature resistance, and ability to resist creep.

The Rise of Expanded PTFE (ePTFE)

Expanded PTFE, or ePTFE, is created by rapidly stretching PTFE under specific conditions. This forms a unique microstructure of strong fibers connected by nodes.

This structure makes ePTFE exceptionally soft and conformable. It can effectively seal with much lower bolt loads, making it ideal for delicate, damaged, or irregular flange surfaces where standard gaskets would fail.

Nanotechnology Integration

The next frontier is the use of nano-scale fillers. These incredibly small particles can be distributed evenly throughout the PTFE material.

This approach enhances properties like wear resistance and thermal conductivity without significantly altering the PTFE's chemical resistance, opening doors for use in high-performance aerospace and semiconductor applications.

Manufacturing Evolution: Precision and Complexity

How a gasket is made is now just as important as what it's made of. Modern manufacturing allows for designs that were previously impossible, solving unique engineering challenges.

Ultra-Precision Machining and Laser Cutting

Modern sealing applications, especially in miniaturized components, demand extreme accuracy.

Laser cutting and ultra-precision machining allow for the creation of gaskets with incredibly tight tolerances and complex shapes. This ensures a perfect fit, which is critical for high-performance and critical-containment seals.

Additive Manufacturing (3D Printing)

For highly complex geometries or rapid prototyping, 3D printing of modified PTFE is an emerging trend.

This technology allows engineers to design and produce one-of-a-kind gaskets or integrated sealing components quickly. It is invaluable for developing solutions for unique equipment or iterating on new designs.

Understanding the Trade-offs

While these advancements offer superior performance, they require careful selection. Choosing the wrong technology can be ineffective and costly.

The Cost of Specialization

Advanced filled materials, ePTFE, and custom-manufactured gaskets carry a higher upfront cost than standard PTFE sheets. Their use is justified in critical applications where seal failure is not an option.

Filler Material Compatibility

Adding fillers to PTFE enhances its mechanical properties but can reduce its chemical inertness. A glass-filled gasket, for example, offers excellent creep resistance but should not be used with hydrofluoric acid or strong alkalis that can attack the glass.

ePTFE is Not a Universal Solution

While ePTFE's conformability is a major advantage, it is not the ideal choice for every situation. In extremely high-pressure applications, a more rigid, filled PTFE gasket may provide better long-term stability and blow-out resistance.

Making the Right Choice for Your Goal

Selecting the correct PTFE gasket technology depends entirely on the problem you are trying to solve.

- If your primary focus is sealing delicate, older, or damaged flanges: Choose ePTFE for its exceptional conformability and low bolt-load requirements.

- If your primary focus is preventing leaks at high temperatures or pressures: Select a modified PTFE with a specialized filler (like silica or graphite) for superior creep resistance.

- If your primary focus is creating a seal for a unique, complex, or miniaturized component: Leverage advanced manufacturing like laser cutting or 3D printing for unparalleled precision.

By understanding these trends, you can move beyond standard solutions and select an engineered material that provides a more reliable and durable seal for your most critical applications.

Summary Table:

| Trend | Key Feature | Primary Benefit |

|---|---|---|

| Modified PTFE | Advanced fillers (glass, graphite, silica) | Enhanced creep resistance, temperature stability |

| Expanded PTFE (ePTFE) | Microporous, fibrous structure | Superior conformability, low bolt load sealing |

| Advanced Manufacturing | Laser cutting, 3D printing | High precision, complex geometries, rapid prototyping |

Ready to solve your most demanding sealing challenges?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get an engineered PTFE solution tailored to your specific pressures, temperatures, and surface conditions.

Contact us today to discuss your application and discover how our advanced PTFE technology can enhance your project's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F