Across a spectrum of demanding industries, PTFE (Polytetrafluoroethylene) gaskets are the standard choice where operational failure is not an option. They are most commonly used in the chemical processing, pharmaceutical, food and beverage, and petrochemical sectors. This widespread adoption is driven by PTFE's unique combination of near-total chemical inertness, a wide operational temperature range, and inherent purity.

The decision to use a PTFE gasket is rarely about the industry itself, but about the specific challenge at hand. Engineers choose PTFE when they face aggressive chemicals, extreme temperatures, or a strict need for non-contamination that would cause other sealing materials to fail.

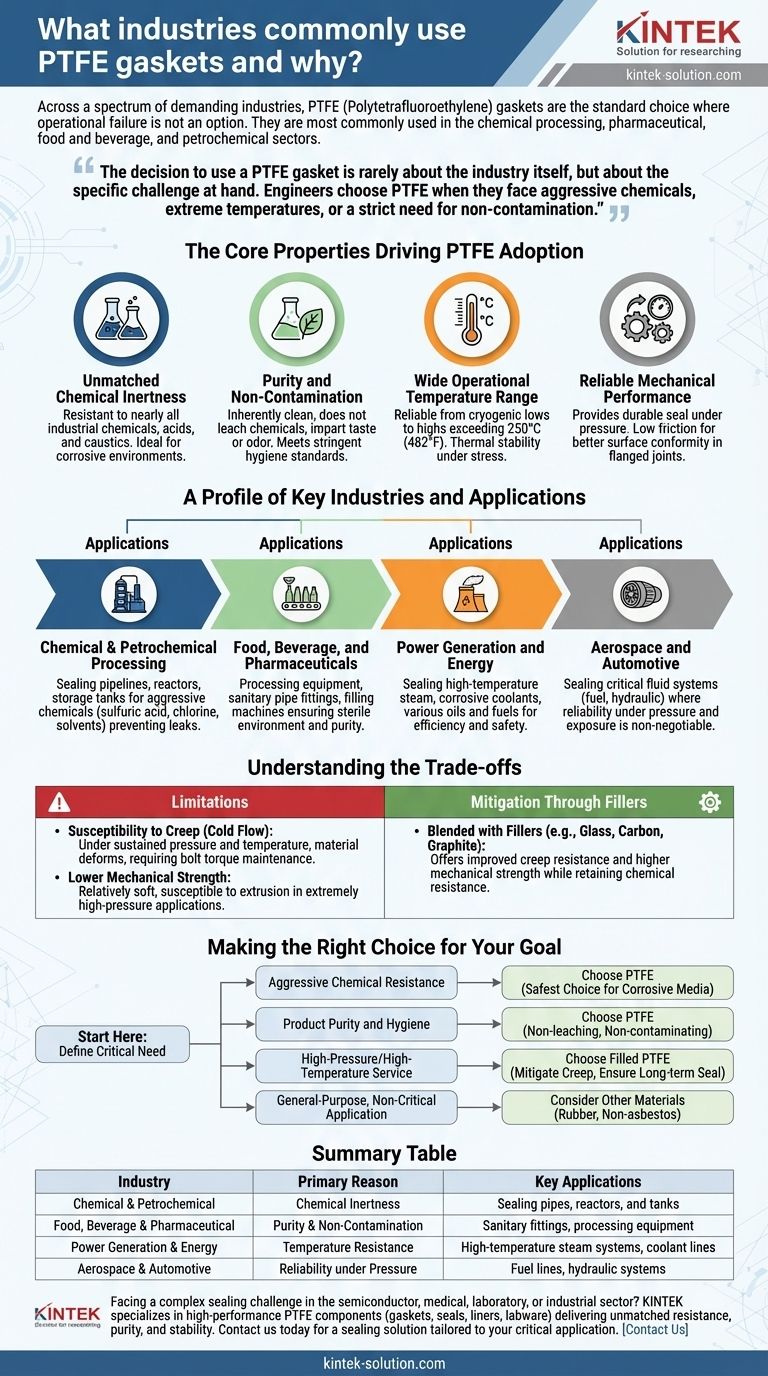

The Core Properties Driving PTFE Adoption

To understand why PTFE is so prevalent, we must look at its fundamental material characteristics. These properties directly solve some of the most difficult sealing problems in modern industry.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and caustics. This makes it an ideal material for sealing pipes, valves, and vessels in environments where corrosive media is present.

It effectively creates a barrier that will not degrade, swell, or break down upon contact, ensuring the integrity of the seal and the safety of the process.

Purity and Non-Contamination

In the food, beverage, and pharmaceutical industries, product purity is paramount. PTFE is an inherently clean material that does not leach chemicals or impart any taste or odor.

This non-contaminating property ensures that the final product remains unadulterated, meeting stringent safety and quality standards.

Wide Operational Temperature Range

PTFE performs reliably across a very broad range of temperatures, from cryogenic lows to highs exceeding 250°C (482°F).

This thermal stability allows it to be used in processes involving high-temperature steam, heated chemicals, or in facilities with significant temperature fluctuations, without compromising the seal.

Reliable Mechanical Performance

While not as strong as metal, PTFE provides a durable and reliable seal under significant pressure. Its low coefficient of friction, often described as "non-stick," allows for better surface conformity and a tighter, more consistent seal in flanged joints.

A Profile of Key Industries and Applications

The core properties of PTFE translate directly into critical applications within specific industrial sectors.

Chemical and Petrochemical Processing

This is the primary domain for PTFE gaskets. They are used to seal pipelines, reactors, and storage tanks containing aggressive chemicals like sulfuric acid, chlorine, and various solvents, preventing dangerous leaks.

Food, Beverage, and Pharmaceuticals

Here, the focus is on hygiene. PTFE gaskets are used in processing equipment, sanitary pipe fittings, and filling machines to ensure a sterile environment and prevent any form of product contamination.

Power Generation and Energy

In power plants, PTFE gaskets are essential for sealing systems that handle high-temperature steam, corrosive coolants, and various oils and fuels, ensuring operational efficiency and safety.

Aerospace and Automotive

These industries rely on PTFE for sealing critical fluid systems. This includes fuel lines, hydraulic systems, and transmission components where reliability under pressure and exposure to specialized fluids is non-negotiable.

Understanding the Trade-offs

No material is perfect. While PTFE is a superior performer, an expert advisor must acknowledge its limitations to ensure proper application.

Susceptibility to Creep

The most significant limitation of PTFE is creep, or "cold flow." Under sustained pressure and temperature, the material can slowly deform, potentially loosening the seal over time. This requires proper bolt torque procedures and sometimes re-torquing.

Lower Mechanical Strength

Compared to metallic or fiber-based gaskets, pure PTFE is relatively soft. In extremely high-pressure applications, it can be susceptible to extrusion from the flange joint.

Mitigation Through Fillers

To counteract these limitations, PTFE is often blended with filler materials like glass, carbon, or graphite. These filled PTFE gaskets offer improved creep resistance and higher mechanical strength while retaining excellent chemical resistance.

Making the Right Choice for Your Goal

Selecting the right gasket material begins with defining your most critical operational need.

- If your primary focus is aggressive chemical resistance: PTFE is almost always the default and safest choice for sealing highly corrosive media.

- If your primary focus is product purity and hygiene: The non-leaching and non-contaminating nature of PTFE makes it essential for food, beverage, and pharmaceutical applications.

- If your primary focus is sealing in high-pressure or high-temperature service: A filled PTFE variant is likely the correct choice to mitigate creep and ensure a long-term, reliable seal.

- If your primary focus is a general-purpose, non-critical application: More cost-effective materials like rubber or non-asbestos composites may be suitable for less demanding environments.

Ultimately, understanding the unique performance profile of PTFE allows you to solve sealing challenges that other materials simply cannot address.

Summary Table:

| Industry | Primary Reason for PTFE Use | Key Applications |

|---|---|---|

| Chemical & Petrochemical | Chemical Inertness | Sealing pipes, reactors, and tanks for aggressive chemicals (acids, solvents) |

| Food, Beverage & Pharmaceutical | Purity & Non-Contamination | Sanitary fittings, processing equipment, filling machines |

| Power Generation & Energy | Temperature Resistance | High-temperature steam systems, coolant lines, fuel/oil systems |

| Aerospace & Automotive | Reliability under Pressure | Fuel lines, hydraulic systems, transmission components |

Facing a complex sealing challenge in the semiconductor, medical, laboratory, or industrial sector? KINTEK specializes in manufacturing high-performance PTFE components—including custom gaskets, seals, liners, and labware—that deliver unmatched chemical resistance, purity, and thermal stability. Whether you need a prototype or high-volume production, our precision engineering ensures reliability where failure is not an option. Contact us today to discuss your specific requirements and let us provide a sealing solution tailored to your critical application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What benefits do PTFE spacer rings offer to customers? Achieve Unmatched Reliability and Lower Costs

- What are some main applications of PTFE as a wear resistant material? Extend Machinery Life with Low-Friction Components

- What factors should engineers consider when selecting PTFE gaskets? Ensure a Perfect Seal for Your Application

- What makes PTFE gaskets resistant to heat and chemicals? The Molecular Secret to Unmatched Performance

- How do PTFE Liners enhance the lifespan of medical devices? Boost Durability & Reliability

- How does PTFE compare to metals in CNC machining? Choose the Right Material for Your Application

- How is Teflon used in the aerospace industry? Essential for Seals, Coatings & Insulation

- What is the melting point of PTFE and its usable temperature range? Master the Thermal Limits for Your Application