Machined Teflon parts are fundamental components in nearly every advanced industry. Common applications range from industrial gears, bushings, fittings, and valves to highly specialized parts in the medical, aerospace, and food processing sectors, such as O-rings, manifolds, bearings, and electrical insulators.

Teflon's value comes from a unique combination of properties: it is chemically inert, has an extremely low coefficient of friction, and tolerates a wide range of temperatures. These benefits make it the ideal choice for critical components, provided you can overcome the distinct challenges of machining such a soft material.

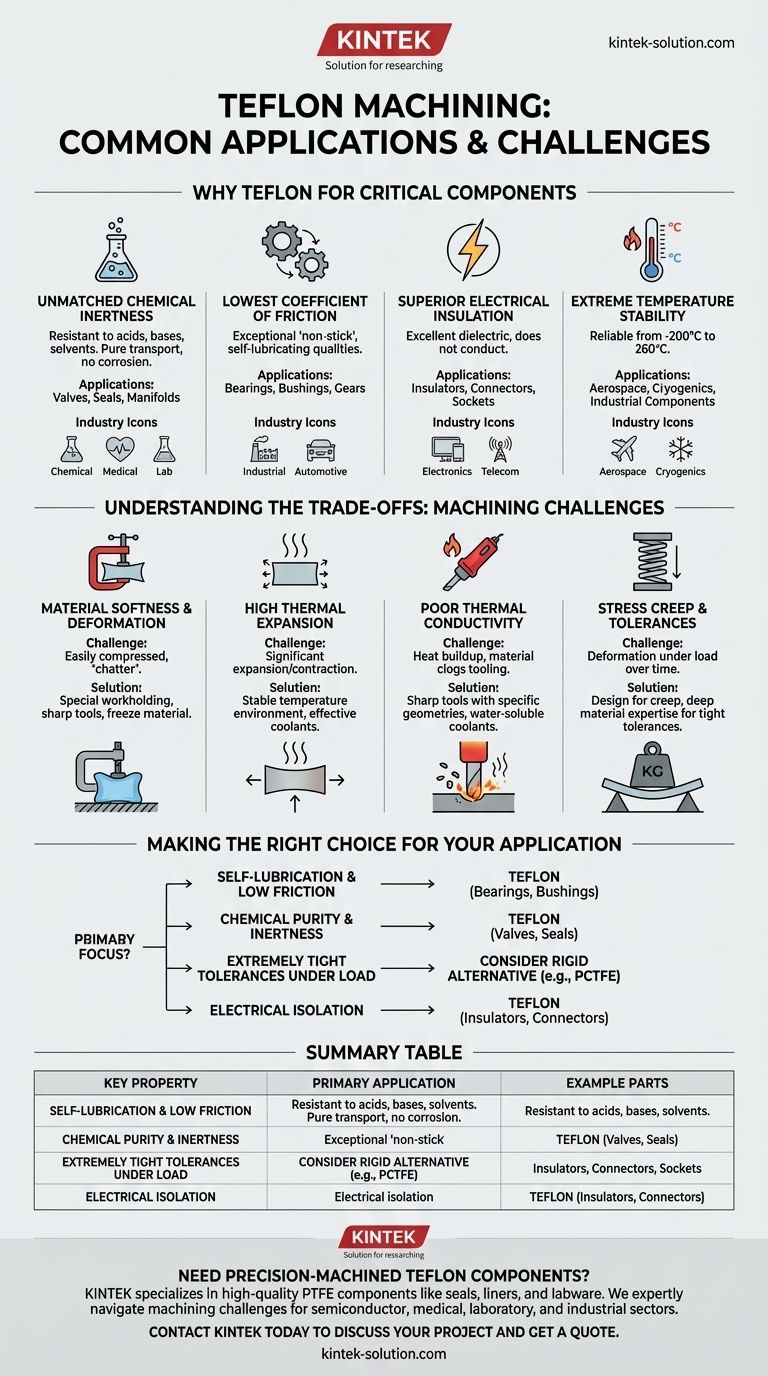

Why Teflon Is Chosen for Critical Components

The decision to machine a part from Teflon (PTFE) is driven by its performance in environments where other materials would fail. Its properties are not just beneficial; they are often mission-critical.

Unmatched Chemical Inertness

Teflon is resistant to nearly all common acids, bases, and solvents. This makes it essential for components used in chemical processing, medical devices, and scientific equipment.

Parts like valves, seals, and manifolds made from Teflon ensure that the material being transported remains pure and that the component itself does not corrode or decompose.

The Lowest Coefficient of Friction

Teflon possesses one of the lowest coefficients of friction of any solid material, giving it exceptional "non-stick" or self-lubricating qualities.

This is why it is the default choice for high-performance bearings, bushings, and gears. These parts can operate smoothly with minimal wear and without external lubrication, reducing maintenance and energy loss.

Superior Electrical Insulation

As an excellent dielectric material, Teflon does not conduct electricity. This property is crucial for the electronics and telecommunications industries.

It is frequently machined into insulators, connectors, and sockets for high-frequency applications where signal integrity and electrical isolation are paramount.

Extreme Temperature Stability

Teflon performs reliably across an exceptionally wide temperature range, from -200°C to 260°C (-328°F to 500°F).

This thermal stability makes it suitable for demanding applications in aerospace, cryogenics, and industrial processing where components are exposed to extreme heat or cold.

Understanding the Trade-offs: The Challenges of Machining Teflon

While its properties are exceptional, Teflon is a notoriously difficult material to machine with precision. Understanding these challenges is key to successful application.

Material Softness and Deformation

Teflon is very soft and can easily be compressed or deformed by clamping pressure during machining. It is also prone to "chatter" if the cutting tool is not perfectly sharp.

To counteract this, machinists use specialized workholding techniques, extremely sharp tooling, and sometimes even temporarily freeze the material to increase its rigidity.

High Thermal Expansion

Teflon expands and contracts significantly with changes in temperature. This high thermal expansion coefficient makes holding tight tolerances a primary challenge.

Maintaining a stable temperature environment and using effective coolants are critical for producing accurate and dimensionally stable parts.

Poor Thermal Conductivity

Unlike metals, Teflon does not dissipate heat well. The friction from the cutting process can cause localized heat buildup, leading the material to become gummy and clog tooling.

This necessitates the use of sharp tools with specific geometries that enhance chip clearance and water-soluble coolants to manage heat at the cutting point.

Stress Creep and Tolerances

Under a sustained load, Teflon can slowly deform over time, a phenomenon known as stress creep. This must be accounted for in the design of any structural or load-bearing component.

This tendency, combined with its softness, makes achieving and maintaining tight dimensional tolerances a specialized skill requiring deep expertise in the material's behavior.

Making the Right Choice for Your Application

Selecting the right material requires balancing its performance benefits against its manufacturing complexities.

- If your primary focus is self-lubrication and low friction: Teflon is the default choice for components like bearings, bushings, and gears where minimal wear is critical.

- If your primary focus is chemical purity and inertness: Its use in medical, food processing, and chemical industries for valves, seals, and manifolds is unmatched.

- If your primary focus is holding extremely tight tolerances under load: You must account for Teflon's thermal expansion and potential for creep, or consider a more rigid alternative like PCTFE for certain applications.

- If your primary focus is electrical isolation: Teflon's dielectric properties make it a superior material for insulators and high-frequency connectors.

By understanding both its unique advantages and its machining challenges, you can confidently specify Teflon for components that demand exceptional performance in harsh environments.

Summary Table:

| Key Property | Primary Application | Example Parts |

|---|---|---|

| Chemical Inertness | Chemical Processing, Medical | Valves, Seals, Manifolds |

| Low Friction | Bearings, Gears | Bushings, Self-lubricating Parts |

| Electrical Insulation | Electronics, Telecom | Insulators, Connectors |

| Temperature Stability | Aerospace, Cryogenics | High/Low-Temperature Components |

Need precision-machined Teflon components for your critical application?

KINTEK specializes in manufacturing high-quality PTFE components like seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We expertly navigate the challenges of machining Teflon to deliver the precision and performance your application demands, from prototypes to high-volume orders.

Contact KINTEK today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support