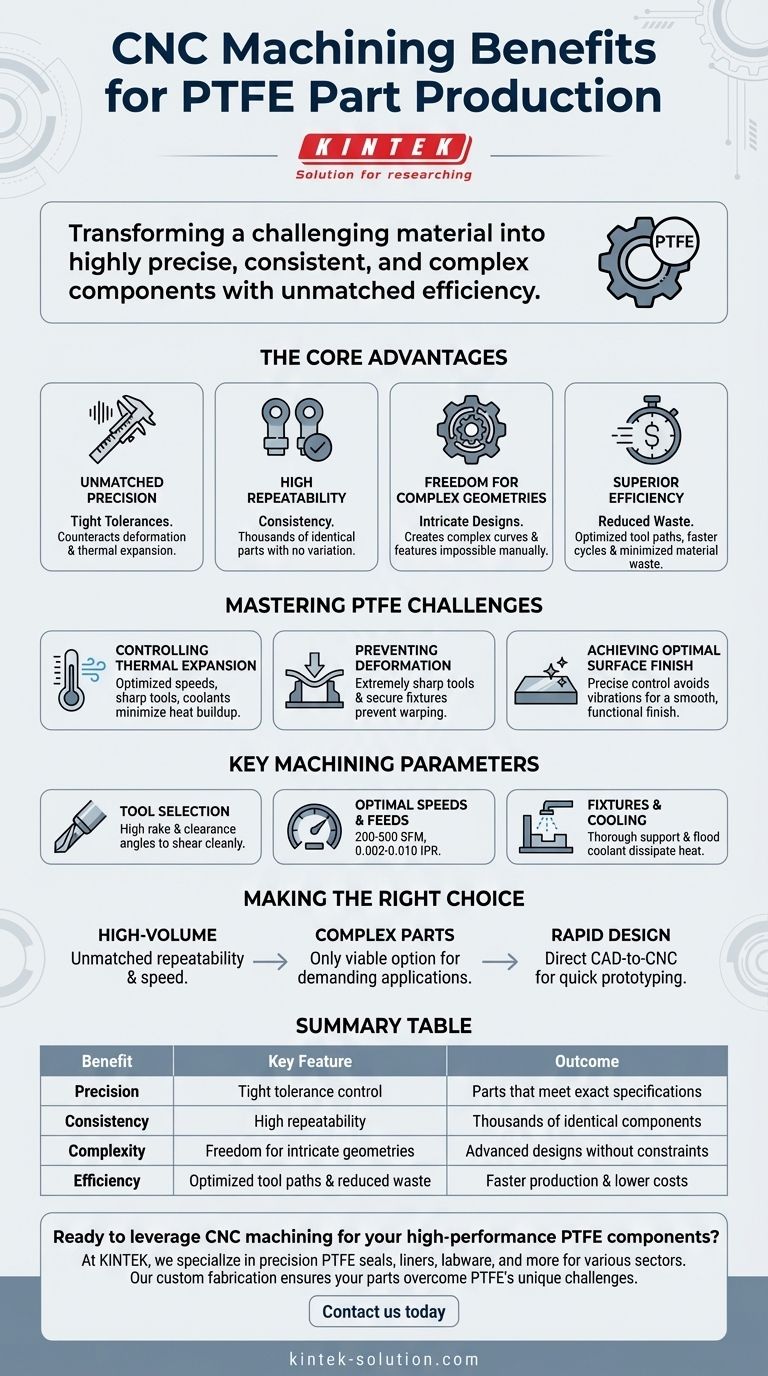

At its core, CNC machining benefits PTFE part production by transforming a challenging material into highly precise, consistent, and complex components with unmatched efficiency. This process leverages automation to overcome PTFE's unique properties, such as thermal expansion and softness, enabling rapid production cycles, minimizing material waste, and ensuring every part meets exacting standards without human error.

The central challenge with PTFE is not just cutting it, but controlling it. CNC machining is the definitive solution, providing the rigid process control necessary to master PTFE's difficult characteristics and unlock its full potential for high-performance applications.

The Core Advantages of CNC Machining PTFE

CNC (Computer Numerical Control) machining isn't just an alternative to manual methods; it is the industry standard for producing quality PTFE components. The benefits are tied directly to overcoming the material's inherent challenges.

Unmatched Precision and Tight Tolerances

PTFE is a soft material prone to deforming under pressure and expanding with heat. CNC machines apply consistent, controlled force and can be programmed with specific parameters to counteract these effects, allowing for the creation of parts with extremely tight tolerances that manual methods cannot replicate.

High Repeatability and Consistency

Automation is the key to consistency. Once a CNC machine is programmed, it can produce thousands of identical parts with no variation. This high repeatability is critical for quality assurance in industries where every component must perform exactly as designed, from medical devices to aerospace.

Freedom for Complex Geometries

The precision of computer-controlled cutting tools allows for the creation of intricate designs, internal features, and complex curves that would be impossible to achieve manually. This empowers engineers to design more effective and efficient parts without being limited by manufacturing constraints.

Superior Efficiency and Reduced Waste

CNC machining optimizes the tool path for every operation, maximizing cutting speed and minimizing wasted movement. This efficiency reduces production time and cost. Furthermore, this precision cutting significantly reduces material waste compared to less controlled methods.

Mastering the Challenges of PTFE Machining

The true value of CNC machining is its ability to manage the specific behaviors of Polytetrafluoroethylene. Success requires a deep understanding of the material itself.

Controlling Thermal Expansion

PTFE has a high rate of thermal expansion. Heat generated during machining can cause the part to expand and then contract, throwing dimensions out of tolerance. CNC processes manage this by using optimized cutting speeds, sharp tools, and often coolants to minimize heat buildup.

Preventing Deformation and Warping

Because PTFE is soft, it can easily be compressed or warped by dull tools or improper clamping. A successful CNC setup uses extremely sharp cutting tools with specific geometries and carefully designed fixtures that hold the material securely without applying excessive pressure.

Achieving an Optimal Surface Finish

Vibration or incorrect tool speeds can result in a poor, chattered surface finish. CNC machines are programmed to maintain a constant cutting engagement, avoiding the vibrations that degrade quality. Precise control over speeds and feeds is essential for a smooth, functional surface.

Key Machining Parameters for PTFE

Achieving the advantages above requires dialing in the right settings. While every part is different, several principles are universal for machining PTFE.

Tool Selection

Tools must be exceptionally sharp with high rake and clearance angles to shear the material cleanly rather than pushing it. This prevents deformation and reduces heat generation.

Optimal Speeds and Feed Rates

The recommended parameters provide a strong starting point. Typical cutting speeds range from 200 to 500 surface feet per minute (SFM), with feed rates between 0.002 and 0.010 inches per revolution (IPR). These settings ensure a clean cut without generating excessive heat or pressure.

The Role of Fixtures and Cooling

Proper fixture design is non-negotiable. The fixture must support the PTFE part thoroughly to prevent it from flexing or vibrating during machining. In many cases, a flood coolant is used to dissipate heat, prevent thermal expansion, and clear away chips.

Making the Right Choice for Your Application

Leveraging CNC machining for PTFE components is a strategic decision that aligns the manufacturing process with your end goal.

- If your primary focus is high-volume production: The unmatched repeatability and speed of CNC machining will ensure consistent quality and lower per-unit costs.

- If your primary focus is complex, mission-critical parts: The ability of CNC to hold tight tolerances and create intricate geometries makes it the only viable option for demanding applications like seals, bearings, or insulators.

- If your primary focus is rapid design iteration: The direct link between CAD software and CNC machines allows you to make design changes quickly and produce new prototype versions in hours or days, not weeks.

Ultimately, CNC machining provides the necessary control and precision to reliably manufacture high-performance PTFE components at any scale.

Summary Table:

| Benefit | Key Feature | Outcome |

|---|---|---|

| Precision | Tight tolerance control | Parts that meet exact specifications |

| Consistency | High repeatability | Thousands of identical components |

| Complexity | Freedom for intricate geometries | Advanced designs without constraints |

| Efficiency | Optimized tool paths & reduced waste | Faster production & lower costs |

Ready to leverage CNC machining for your high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts overcome PTFE's unique challenges, delivering unmatched consistency and complex geometries.

Contact us today to discuss your project and discover how our CNC machining solutions can bring your most demanding PTFE designs to life.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability