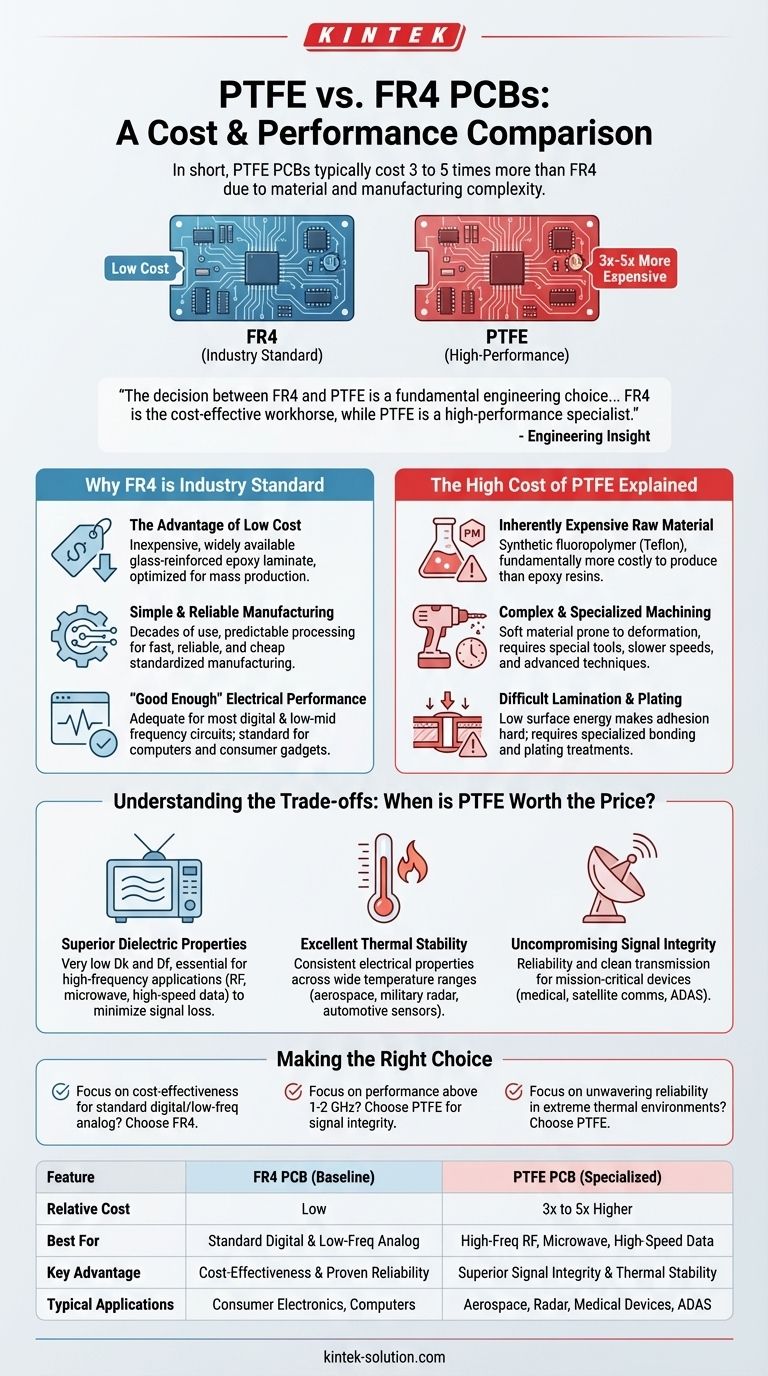

In short, the cost difference is substantial. A Printed Circuit Board (PCB) made from PTFE (Polytetrafluoroethylene) will typically cost 3 to 5 times more than an equivalent board made from the industry-standard FR4 material. This significant price increase is a direct result of both the raw material expense and the far more complex and specialized manufacturing processes required for PTFE.

The decision between FR4 and PTFE is not merely about budget; it is a fundamental engineering choice. FR4 is the versatile, cost-effective workhorse for the vast majority of electronic applications, while PTFE is a high-performance specialist reserved for systems where signal integrity at high frequencies is absolutely mission-critical.

Why FR4 is the Industry Standard

FR4 has become the default material for PCBs for several clear and practical reasons. Understanding its strengths provides the necessary context for why deviating from it costs so much more.

The Advantage of Low Cost

FR4 is a glass-reinforced epoxy laminate. The materials are widely available and inexpensive, and the process for manufacturing FR4 sheets is mature and highly optimized for mass production.

Simple and Reliable Manufacturing

Decades of use have made manufacturing with FR4 a predictable science. Its rigidity and thermal properties are well-understood, allowing for standardized drilling, plating, and lamination processes that are fast, reliable, and cheap.

"Good Enough" Electrical Performance

For most digital and low-to-mid frequency analog circuits, FR4's electrical properties are perfectly adequate. It provides sufficient insulation and maintains signal integrity for the countless applications that define our modern digital world, from computers to consumer gadgets.

The High Cost of PTFE Explained

The premium price for PTFE PCBs is not arbitrary. It stems from inherent challenges in both the material's nature and the precision required to fabricate it correctly.

Inherently Expensive Raw Material

PTFE, a synthetic fluoropolymer often known by the brand name Teflon, is fundamentally a more advanced and costly polymer to produce than the simple epoxy resins used in FR4.

Complex and Specialized Machining

PTFE is a much softer material than FR4. This softness makes it prone to smearing, deformation, and gumming up drill bits during the machining process. It requires special tools, slower drilling speeds, and advanced de-burring techniques to create clean holes and precise traces.

Difficult Lamination and Plating

The chemical inertness and low surface energy that make PTFE a great insulator also make it very difficult for other materials to adhere to it. The process of bonding copper layers and plating copper into through-holes is significantly more complex and requires specialized chemical treatments not needed for FR4.

Understanding the Trade-offs: When is PTFE Worth the Price?

The decision to absorb the high cost of PTFE is always driven by a need for electrical performance that FR4 simply cannot deliver, especially as signal frequencies increase.

Superior Dielectric Properties

This is the single most important reason to choose PTFE. It has a very low and stable dielectric constant (Dk) and a low dissipation factor (Df). In simple terms, this means far less of the electrical signal is lost or distorted as it travels through the PCB, a critical factor for high-frequency applications like RF, microwave, and high-speed data transmission.

Excellent Thermal Stability

PTFE maintains its excellent electrical properties over a much wider temperature range than FR4. This ensures consistent, predictable performance in demanding environments such as aerospace, military radar, or automotive sensors.

Uncompromising Signal Integrity

In applications where signal failure is not an option, the cost becomes a secondary concern. The reliability and clean signal transmission offered by PTFE are essential for medical devices, satellite communications, and advanced driver-assistance systems (ADAS).

Making the Right Choice for Your Application

Ultimately, the material must match the task. Over-engineering with PTFE is a waste of money, while using FR4 in a high-frequency design is a recipe for failure.

- If your primary focus is cost-effectiveness for standard digital or low-frequency analog circuits: FR4 is unequivocally the correct and most practical choice.

- If your primary focus is performance above 1-2 GHz: The superior dielectric properties of PTFE become non-negotiable to maintain signal integrity and minimize loss.

- If your primary focus is unwavering reliability in extreme thermal environments: PTFE's stability provides a performance margin that justifies the cost in mission-critical aerospace, industrial, or military hardware.

Choosing the right material is an engineering decision that directly balances your project's budget against its required performance.

Summary Table:

| Feature | FR4 PCB | PTFE PCB |

|---|---|---|

| Relative Cost | Low (Baseline) | 3x to 5x Higher |

| Best For | Standard Digital & Low-Freq Analog | High-Freq RF, Microwave, High-Speed Data |

| Key Advantage | Cost-Effectiveness & Proven Reliability | Superior Signal Integrity & Thermal Stability |

| Typical Applications | Consumer Electronics, Computers | Aerospace, Radar, Medical Devices, ADAS |

Need High-Performance PTFE Components for Your Critical Application?

Navigating the trade-offs between cost and performance is essential. At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the demanding requirements of high-frequency and extreme-environment applications. Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards for reliability and performance.

Let's discuss how our custom PTFE fabrication can support your mission-critical designs. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials