In the highly regulated food and beverage industry, material selection is a matter of safety, compliance, and operational reliability. PTFE (polytetrafluoroethylene) guide strips are exceptionally suitable for this environment because they meet stringent FDA standards for food contact, are chemically inert, and can withstand the high temperatures and harsh cleaning cycles common in food processing. Their low-friction, non-stick surface also plays a critical role in maintaining hygiene and preventing contamination.

The core reason for PTFE's widespread use is not a single feature, but its unique combination of properties. It simultaneously ensures product purity by not reacting with food and operational reliability by resisting the industry's demanding physical and chemical stresses.

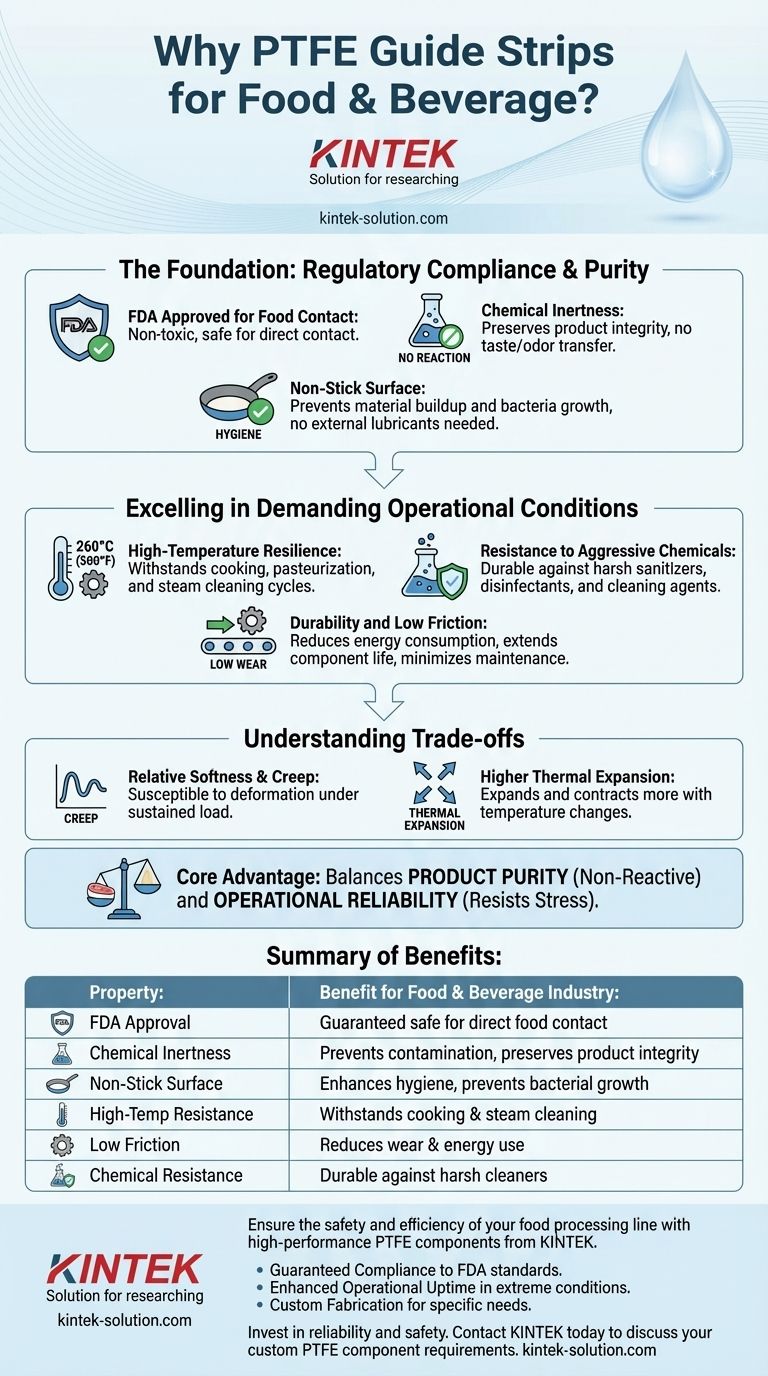

The Foundation: Regulatory Compliance and Purity

In food processing, the material touching the product cannot be an afterthought. It is a critical control point for safety and quality. PTFE excels because its fundamental properties are inherently suited for this role.

FDA Approval for Food Contact

The most critical prerequisite for any material used in this sector is regulatory approval. PTFE is FDA-approved for applications involving direct food contact.

This approval confirms that the material is non-toxic and will not leach harmful substances into food products, making it a trusted choice for components like guide strips, gaskets, and machinery liners.

Chemical Inertness Preserves Product Integrity

PTFE is one of the most chemically non-reactive plastics known. Think of it as a perfect shield at the molecular level; it does not impart any taste, odor, or chemical component to the food products it touches.

This property is vital in the dairy and beverage industries, where even minute contamination can alter a product's flavor profile and compromise an entire batch.

Preventing Contamination Through Surface Properties

PTFE's famous non-stick surface is a major asset for hygiene. It prevents food materials and residues from building up on equipment surfaces, which denies bacteria a place to grow.

Furthermore, its low-friction nature means many PTFE components, such as non-metal bearings and guide strips, do not require grease or external lubricants. This eliminates a significant potential source of product contamination.

Excelling in Demanding Operational Conditions

Beyond safety and purity, equipment components must survive the rigors of a high-throughput production environment. PTFE's physical resilience makes it a durable and cost-effective choice.

High-Temperature Resilience

Food processing often involves extreme temperatures, from cooking and pasteurization to high-temperature steam cleaning for sterilization.

PTFE components can consistently operate at temperatures up to 260°C (500°F). This ensures they do not warp, melt, or degrade during critical production and sanitation cycles.

Resistance to Aggressive Chemicals

The food and beverage industry relies on powerful sanitizers, disinfectants, and cleaning agents to maintain a hygienic environment.

PTFE offers excellent resistance to corrosion and chemical attack. This means guide strips and seals will not break down when exposed to these harsh substances, preventing equipment failure and potential leaks that could compromise food safety.

Durability and Low Friction

On a conveyor system, guide strips are subject to constant use. PTFE's low coefficient of friction minimizes wear and tear on both the strip and the conveyor belt itself.

This low-friction movement reduces the energy needed to run the system, extends the operational life of the components, and results in less maintenance downtime.

Understanding the Trade-offs

No material is perfect for every single scenario. While PTFE is an exceptional choice, it's important to understand its limitations to ensure proper design and application.

Relative Softness and Creep

Compared to metals, PTFE is a relatively soft material. It can be susceptible to "creep," which is slow deformation under a sustained load, and can be damaged by abrasion from very sharp or hard materials. This must be considered in high-load structural applications.

Higher Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. Engineers must account for the fact that it will expand and contract more significantly with temperature changes to maintain precise clearances and tight seals in machinery.

Initial Cost

The initial investment for PTFE components can be higher than for parts made from other plastics or metals. However, this cost is often justified by a longer service life, reduced maintenance, and the prevention of costly product contamination incidents.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision rooted in balancing safety, performance, and long-term value.

- If your primary focus is product purity and safety: PTFE's FDA compliance and chemically inert nature make it the superior choice for direct food contact.

- If your primary focus is operational uptime in high-heat environments: PTFE's ability to withstand temperatures up to 260°C and resist harsh cleaning agents ensures long component life.

- If your primary focus is reducing maintenance and contamination risk: PTFE's low-friction, non-stick surface minimizes material buildup and can eliminate the need for lubricants.

Ultimately, selecting PTFE for guide strips and other components is an investment in consistent, safe, and efficient food production.

Summary Table:

| Property | Benefit for Food & Beverage Industry |

|---|---|

| FDA Approval | Guaranteed safe for direct food contact |

| Chemical Inertness | Prevents contamination, preserves product integrity |

| Non-Stick Surface | Enhances hygiene, prevents bacterial growth |

| High-Temperature Resistance (up to 260°C) | Withstands cooking, pasteurization, and steam cleaning |

| Low Friction | Reduces wear, energy consumption, and maintenance |

| Chemical Resistance | Durable against harsh sanitizers and cleaners |

Ensure the safety and efficiency of your food processing line with high-performance PTFE components from KINTEK.

As specialists in precision PTFE manufacturing for the semiconductor, medical, laboratory, and industrial sectors, we understand the critical need for materials that meet the highest standards of purity and durability. Our PTFE guide strips, seals, liners, and custom labware are engineered to provide:

- Guaranteed Compliance: All our PTFE components are manufactured to meet strict FDA standards for food contact, ensuring your products remain uncontaminated.

- Enhanced Operational Uptime: Withstand extreme temperatures and aggressive cleaning cycles, reducing downtime and maintenance costs.

- Custom Fabrication: We work with you from prototype to high-volume production to create PTFE parts that perfectly fit your specific equipment and application needs.

Invest in reliability and safety. Contact KINTEK today to discuss your custom PTFE component requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the steps to create a custom Teflon sheet for a heat press? Boost Your Production Efficiency & Quality

- How can thermal expansion be managed during PTFE machining? Master Precision with a Multi-Faceted Strategy

- Why is PTFE's low friction property beneficial in manufacturing? To Reduce Wear, Downtime & Energy Costs

- What are the considerations for managing PTFE's creep and thermal expansion? Ensure Dimensional Stability & Performance

- How does PTFE reduce friction wear in piping systems? Prevent Abrasive Damage and System Failure

- What are the primary uses of Teflon encapsulated O-Rings? Seal Against Aggressive Chemicals & High Temperatures

- What are the media resistance properties of PTFE with fillers? Retains Chemical Inertness While Boosting Durability

- What factors should be considered when choosing between PTFE and conventional oil seals? Optimize Performance and Cost