In short, adding fillers to PTFE does not fundamentally change its exceptional media resistance. Filled PTFE remains resistant to nearly all chemicals across the entire 0-14 pH range, making it suitable for the most demanding applications. The primary exceptions for both filled and unfilled PTFE are highly reactive substances like molten alkali metals and certain fluorine compounds, such as pressurized fluorine gas.

The decision to use filled PTFE is not about gaining chemical resistance, but about trading the ultimate purity of virgin PTFE for a dramatic improvement in mechanical properties like wear resistance, creep resistance, and thermal conductivity.

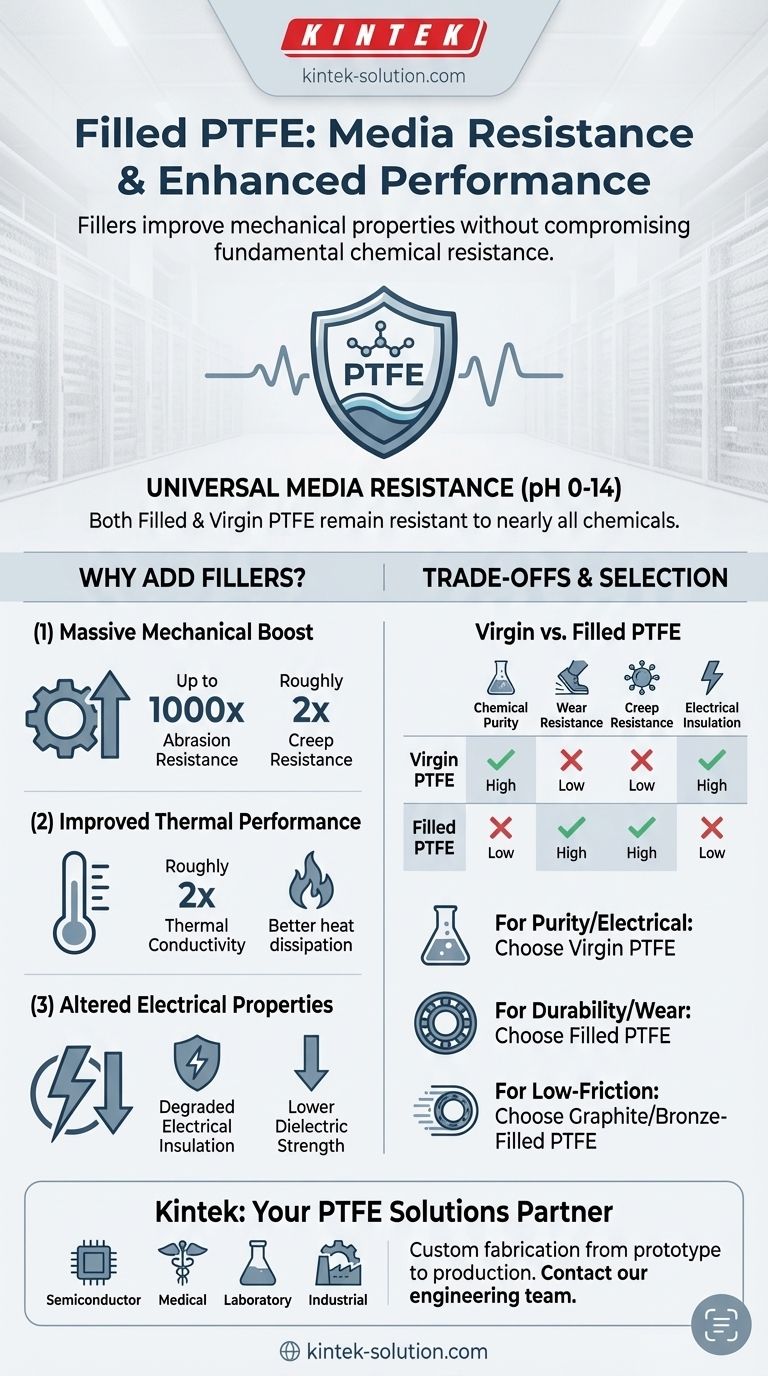

Why Fillers Are Added to PTFE

Virgin (unfilled) PTFE is chemically inert but mechanically soft. Fillers are introduced to create a composite material that retains PTFE’s key chemical properties while drastically enhancing its physical performance for industrial applications.

A Massive Boost in Mechanical Strength

The primary benefit of adding fillers is a significant improvement in mechanical integrity. This is especially critical in dynamic sealing or bearing applications.

Research shows that filled PTFE can have up to 1000 times the abrasion resistance of unfilled PTFE. Fillers also roughly double the material's resistance to creep, which is the tendency to deform under constant stress.

Improved Thermal Performance

Fillers act as a bridge for heat to escape, improving the material's performance in high-temperature or high-speed applications where friction generates heat.

A filled PTFE compound can have twice the thermal conductivity of virgin PTFE. This helps prevent heat buildup at sealing surfaces, extending the service life of the component.

Altered Electrical Properties

While enhancing mechanical properties, fillers generally degrade PTFE’s excellent electrical insulation capabilities.

Fillers increase the dielectric constant and dissipation factor while decreasing the dielectric strength of the material. This makes virgin PTFE the superior choice for high-performance electrical insulators.

The Unchanged Chemical Resistance Profile

For nearly all practical purposes, the list of chemicals that filled PTFE can handle is identical to that of virgin PTFE. The base polymer’s inertness is the dominant factor.

The Same Universal Resistance

Filled PTFE gaskets and seals are resistant to the vast majority of chemicals, acids, and bases. They are stable against atmospheric aging, oxygen, UV light, and radiation.

The material is also non-absorbent and features extremely low permeability, making it a reliable barrier against moisture and gases.

The Key Exceptions Remain

The well-known limitations of PTFE apply equally to its filled variants. You must avoid using it with:

- Molten or liquid alkali metals (e.g., sodium, potassium).

- Free fluorine atoms or high-pressure fluorine gas.

While some halogen-containing compounds may migrate through PTFE, this is a temporary effect and does not cause permanent material damage or swelling.

Understanding the Trade-offs

Choosing between filled and unfilled PTFE requires a clear understanding of your application's primary demand—is it chemical purity or mechanical durability?

Purity vs. Performance

Virgin PTFE offers the highest chemical purity and is compliant with FDA regulations for food and medical use. Its superior electrical insulation makes it the only choice for critical electronics.

Filled PTFE is engineered for industrial machinery. Fillers like glass fiber, carbon, and bronze provide the toughness needed for bearings, piston rings, and high-pressure seals where wear and tear are the main concerns.

Machinability and Hardness

Virgin PTFE is soft and ductile, allowing for easy machining with minimal tool wear.

The addition of abrasive fillers makes filled PTFE significantly harder. Machining it requires lower speeds, specialized tooling, and careful thermal management to achieve precise tolerances.

The Filler Type Matters

The choice of filler fine-tunes the material's properties. For example, glass-filled PTFE offers excellent all-around strength, while carbon-filled PTFE enhances hardness and creep resistance. Graphite-filled PTFE provides an extremely low coefficient of friction for non-lubricated dynamic seals.

How to Select the Right Material

Your application's specific requirements will dictate the best choice.

- If your primary focus is ultimate chemical purity, food/medical safety, or electrical insulation: Choose virgin (unfilled) PTFE.

- If your primary focus is wear resistance, load-bearing capacity, or thermal stability in a dynamic system: Choose a filled PTFE compound.

- If your primary focus is a non-lubricated, low-friction dynamic seal: A graphite-filled or bronze-filled PTFE is likely the optimal choice.

Ultimately, fillers enhance PTFE's mechanical capabilities without compromising the universal chemical resistance that makes it a cornerstone of high-performance engineering.

Summary Table:

| Property | Virgin PTFE | Filled PTFE |

|---|---|---|

| Chemical Resistance | Excellent (0-14 pH) | Excellent (0-14 pH) |

| Wear/Abrasion Resistance | Low | Up to 1000x Better |

| Creep Resistance | Low | Roughly 2x Better |

| Thermal Conductivity | Low | Roughly 2x Better |

| Electrical Insulation | Excellent | Degraded |

| Primary Use Case | Chemical Purity, Electrical, Food/Medical | Mechanical Durability, Bearings, Seals |

Need High-Performance PTFE Components?

Whether your application demands the ultimate chemical purity of virgin PTFE or the superior mechanical strength of a filled compound, KINTEK has the expertise to deliver.

We manufacture precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors.

We specialize in custom fabrication, guiding you from prototype to high-volume production to ensure you get the exact material properties your project requires.

Contact our engineering team today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries