At its core, PTFE reduces friction wear in piping systems because of its exceptionally low coefficient of friction. This property, one of the lowest of any solid material, creates an extremely smooth, non-stick surface that allows pipes to glide effortlessly against their supports during movement, preventing the abrasive grinding that leads to wear and tear.

The true value of PTFE in a piping system is not just its low friction but its ability to function as a comprehensive isolator. It protects pipes from a combination of destructive forces—friction, vibration, and thermal expansion—ultimately preventing premature fatigue and failure throughout the entire system.

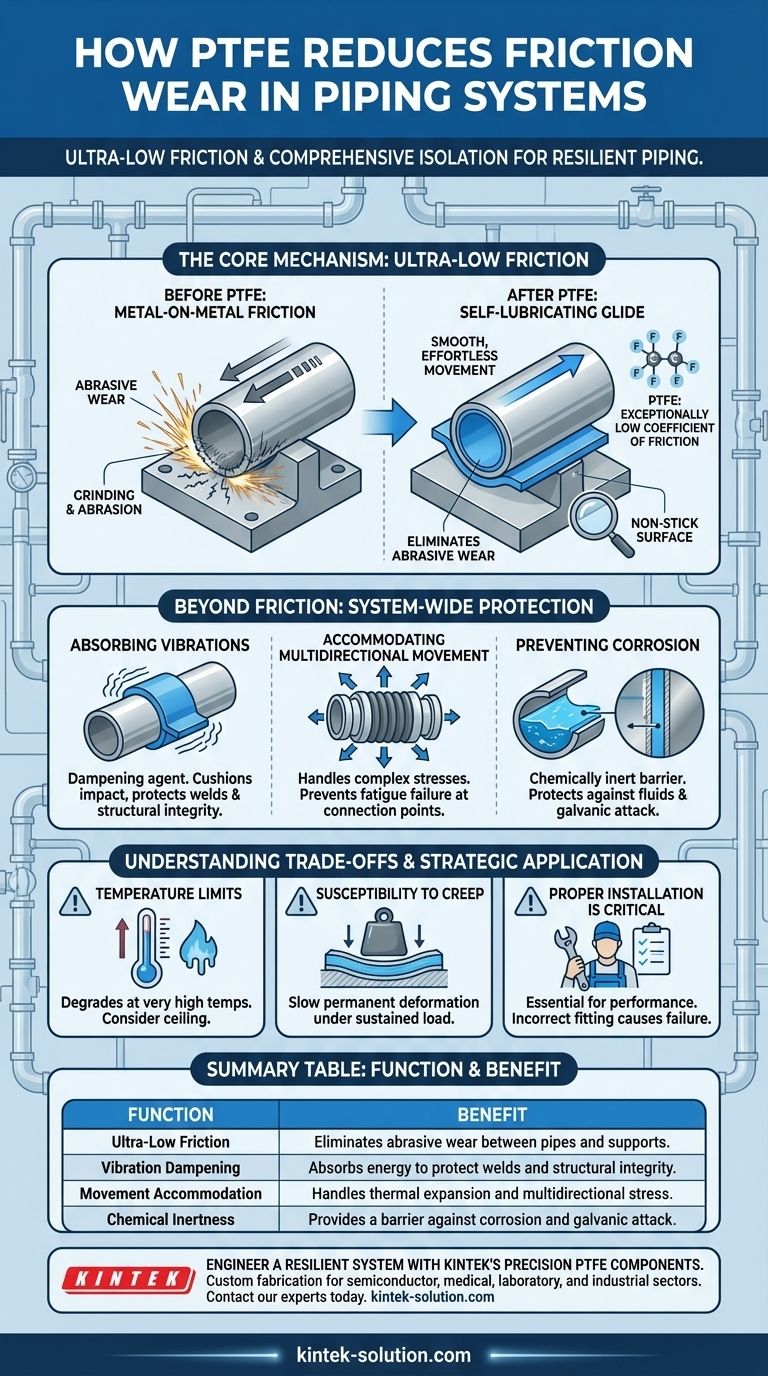

The Core Mechanism: An Ultra-Low Coefficient of Friction

PTFE, commonly known by the brand name Teflon, fundamentally changes the interaction between a pipe and its support structures. Instead of metal grinding on metal, the components slide on a self-lubricating, non-stick surface.

How PTFE Minimizes Abrasive Wear

The primary function is to eliminate the source of abrasive wear. By introducing a PTFE liner or slide plate, you create a sacrificial, low-friction surface.

This allows pipes to move smoothly without scraping or eroding the surface of either the pipe itself or its support structure. This dramatically extends the lifespan of both components.

The Impact on System Movement

Piping systems are not static; they constantly expand and contract due to thermal cycling. PTFE allows this natural movement to occur without resistance.

Without it, this constant motion would create high-stress friction points, leading to localized wear, material fatigue, and potential points of failure over time.

Beyond Friction: Addressing System-Wide Stress

While reducing friction is the most direct benefit, PTFE's properties solve a wider range of problems that contribute to the long-term degradation of piping systems.

Absorbing Destructive Vibrations

Mechanical equipment and fluid dynamics introduce constant vibrations into a piping system. PTFE acts as a dampening agent.

PTFE liners and pads absorb this vibrational energy, cushioning the impact between the pipe and its supports. This preserves the structural integrity of the entire assembly and reduces stress on welds and joints.

Accommodating Multidirectional Movement

Pipes move in more than one direction. PTFE compensators and expansion joints leverage the material's flexibility to absorb complex stresses.

These components safely handle axial compression, lateral deflection, and angular rotation. This prevents stress from building up and causing fatigue failure at fixed connection points, such as nozzles on sensitive equipment.

Preventing Corrosion and Chemical Attack

PTFE is almost completely chemically inert. This provides a critical barrier against two common forms of corrosion.

First, it can be used to line pipes and valves, protecting the structural metal from corrosive fluids. Second, when placed between a pipe and a support made of a different metal, it prevents the galvanic corrosion that can occur at the contact point.

Understanding the Trade-offs

Integrating PTFE is a deliberate engineering decision, not a universal fix. Understanding its limitations is crucial for proper application.

Temperature Limitations

While PTFE has a wide operating temperature range, it has its limits. At very high temperatures, it can lose its structural integrity and begin to degrade. This ceiling must be considered during the system design phase.

Susceptibility to Creep

Under a sustained, heavy load, especially at elevated temperatures, PTFE can be subject to "creep," a slow, permanent deformation. This must be accounted for when designing components like support pads for very heavy piping.

Proper Installation is Critical

The benefits of PTFE are only realized if it is installed correctly. Improperly fitted liners or poorly designed slide plates can fail to deliver the expected performance and may even introduce new problems.

Making the Right Choice for Your Goal

Strategically applying PTFE components allows you to target the most significant points of failure in your piping system.

- If your primary focus is longevity and reduced maintenance: Use PTFE slide plates and pipe support liners to eliminate wear from routine thermal expansion and contraction.

- If your primary focus is system reliability near sensitive equipment: Use PTFE compensators and flexible joints to absorb vibration and complex movements, protecting equipment nozzles from fatigue.

- If your primary focus is handling corrosive fluids: Use PTFE-lined pipes, valves, and flanges to protect the system's structural materials and prevent contamination.

By understanding PTFE's multifaceted role, you can engineer a more resilient, reliable, and cost-effective piping system.

Summary Table:

| Function | Benefit |

|---|---|

| Ultra-Low Friction | Eliminates abrasive wear between pipes and supports. |

| Vibration Dampening | Absorbs energy to protect welds and structural integrity. |

| Movement Accommodation | Handles thermal expansion and multidirectional stress. |

| Chemical Inertness | Provides a barrier against corrosion and galvanic attack. |

Engineer a more resilient and cost-effective piping system with KINTEK's precision PTFE components.

Whether you need to eliminate abrasive wear with custom PTFE slide plates and liners, protect sensitive equipment with PTFE compensators, or handle corrosive fluids with PTFE-lined pipes and valves, KINTEK has the solution. We specialize in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors, from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE components can enhance your system's longevity and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications