The primary factors when choosing between PTFE and conventional oil seals are the application's operating temperature, chemical environment, pressure, and friction requirements. PTFE seals are engineered for extreme conditions, offering superior resistance to heat, chemicals, and pressure, while conventional rubber seals provide a cost-effective solution for standard, less demanding applications.

The decision between PTFE and conventional oil seals is a direct trade-off. You are balancing the exceptional durability and performance of PTFE in harsh environments against the economic efficiency of conventional seals for general-purpose use.

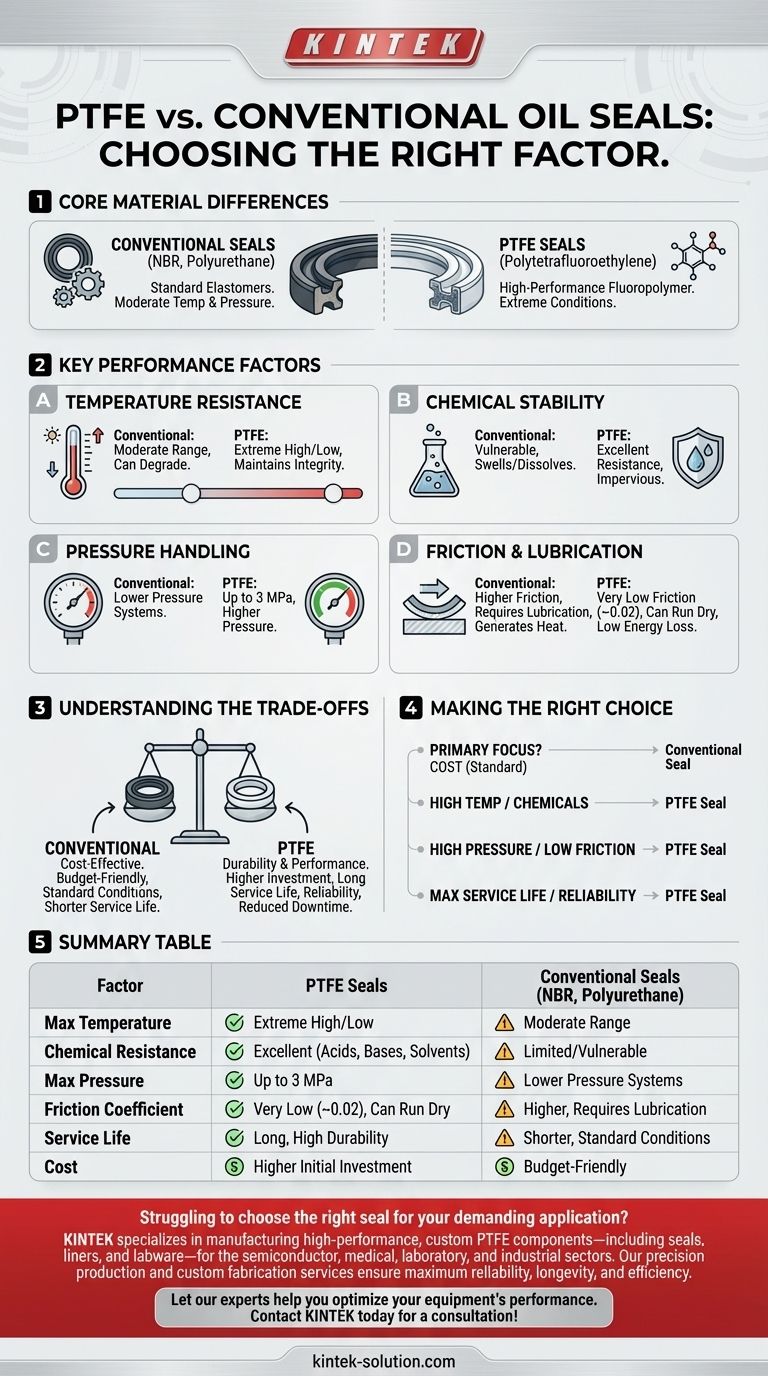

Core Material Differences

The fundamental distinction between these seals lies in their base materials, which dictates their performance characteristics.

Conventional Seals (NBR, Polyurethane)

Conventional oil seals are typically made from rubber or polyurethane materials, such as Nitrile Butadiene Rubber (NBR). These materials are well-suited for standard lubricated conditions with moderate temperatures and pressures.

PTFE Seals (Polytetrafluoroethylene)

PTFE oil seals are made from polytetrafluoroethylene, a high-performance fluoropolymer. This advanced material provides properties that standard elastomers cannot match, making it ideal for specialized and demanding industrial applications.

Key Performance Factors Explained

Understanding how each seal type performs under specific stressors is critical for making an informed decision.

Temperature Resistance

PTFE seals excel in both extreme high and low temperatures, maintaining their integrity where conventional seals would fail. Conventional rubber seals are designed for moderate temperature ranges and can become brittle or degrade outside of their specified limits.

Chemical Stability

PTFE offers nearly universal chemical resistance, making it impervious to erosion from strong acids, bases, and solvents. Conventional rubber seals are vulnerable to certain chemicals and oils, which can cause them to swell, harden, or dissolve over time.

Pressure Handling

PTFE seals are built for higher-pressure environments, capable of withstanding up to 3 MPa. Conventional seals are typically specified for lower-pressure systems and are best suited for general mechanical sealing needs.

Friction and Lubrication

PTFE has an exceptionally low coefficient of friction (around 0.02), which minimizes energy loss and heat generation. This allows it to run dry without lubrication in some cases. Conventional seals have higher friction, require constant lubrication, and can generate heat that accelerates wear.

Understanding the Trade-offs

Each seal type presents a distinct value proposition based on its balance of cost, durability, and performance.

Service Life and Durability

Due to its superior wear and chemical resistance, a PTFE seal offers a significantly longer service life, especially in high-frequency or high-pressure applications. Conventional seals have a shorter lifespan and are more susceptible to aging and leakage when exposed to harsh conditions.

Cost Considerations

Conventional seals are the budget-friendly option for common applications where operating conditions are not severe. PTFE seals represent a higher initial investment, but this cost is often justified by their extended lifespan and reliability, which reduces equipment downtime and long-term maintenance costs.

Making the Right Choice for Your Application

Your final selection should be directly aligned with the specific demands of your equipment and its operating environment.

- If your primary focus is cost-effectiveness for standard conditions: A conventional rubber seal is the most practical and economical choice.

- If your primary focus is high temperatures or aggressive chemicals: PTFE is the only reliable option to ensure seal integrity and prevent failure.

- If your primary focus is high-pressure sealing and low friction: The superior material properties of PTFE are required for safe and efficient operation.

- If your primary focus is maximum service life and reliability: The long-term durability of PTFE justifies the initial investment by minimizing future maintenance.

Choosing the correct seal is a strategic decision that directly impacts your equipment's long-term reliability and operational efficiency.

Summary Table:

| Factor | PTFE Seals | Conventional Seals (NBR, Polyurethane) |

|---|---|---|

| Max Temperature | Extreme High/Low | Moderate Range |

| Chemical Resistance | Excellent (Acids, Bases, Solvents) | Limited/Vulnerable |

| Max Pressure | Up to 3 MPa | Lower Pressure Systems |

| Friction Coefficient | Very Low (~0.02), Can Run Dry | Higher, Requires Lubrication |

| Service Life | Long, High Durability | Shorter, Standard Conditions |

| Cost | Higher Initial Investment | Budget-Friendly |

Struggling to choose the right seal for your demanding application? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a seal that delivers maximum reliability, longevity, and efficiency.

Let our experts help you optimize your equipment's performance. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions