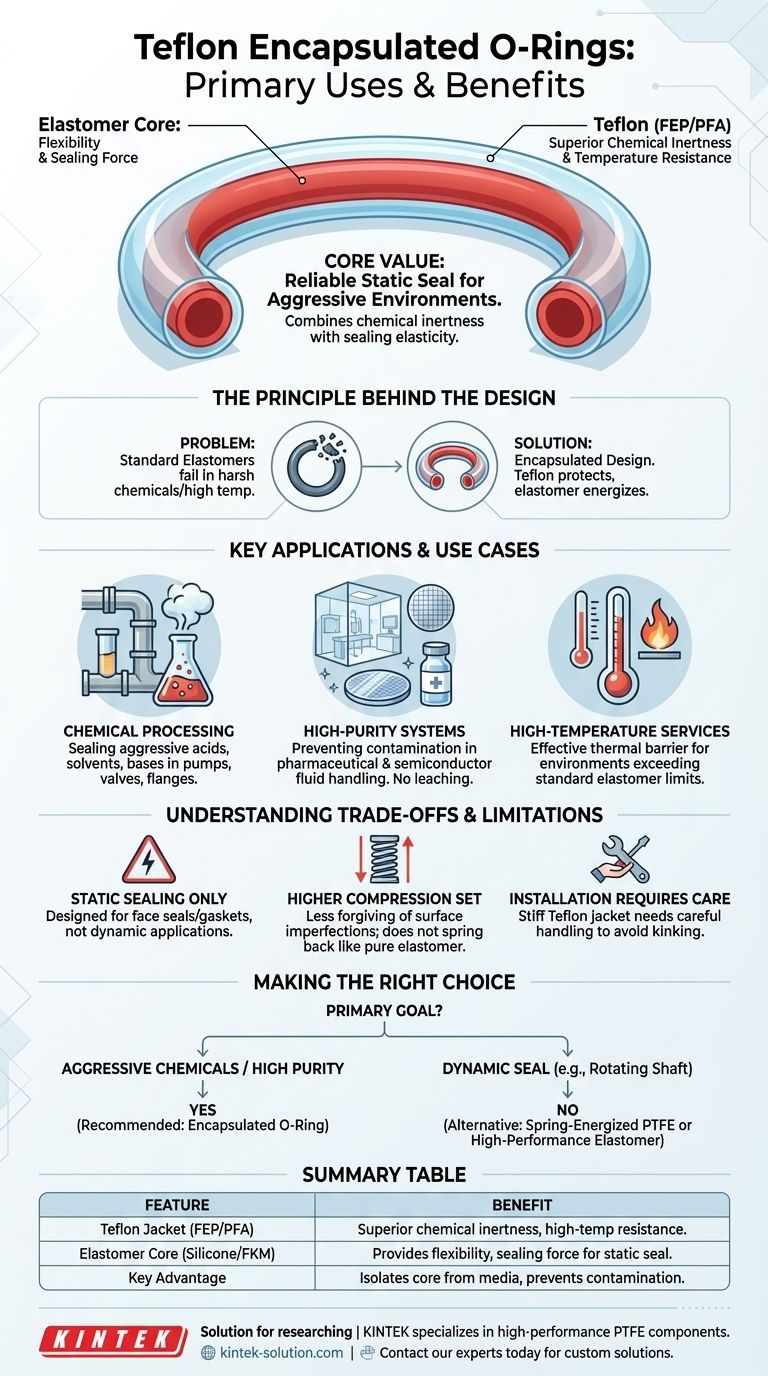

The primary use of Teflon encapsulated O-rings is to provide a reliable static seal in applications exposed to aggressive chemicals or extreme temperatures where a standard elastomeric O-ring would fail. This specialized design is critical in industries like chemical processing, pharmaceutical manufacturing, aerospace, and high-purity semiconductor fluid handling systems.

A Teflon encapsulated O-ring is a composite seal designed for demanding environments. It combines the superior chemical inertness of a Teflon jacket with the flexibility and sealing force of an inner elastomer core, creating a solution that withstands conditions that would destroy a standard O-ring.

The Principle Behind the Design

Teflon encapsulated O-rings solve a fundamental material conflict. While elastomers like silicone provide excellent flexibility for sealing, they have limited chemical resistance. Conversely, solid Teflon is chemically inert but too rigid to create an effective, resilient seal on its own.

The Protective Teflon Jacket

The outer layer of the O-ring is a seamless jacket made from Teflon FEP or PFA. This layer is the component that comes into direct contact with the process media.

Its primary function is to provide a robust barrier against chemical attack and high temperatures, protecting the more vulnerable core.

The Flexible Elastomer Core

Inside the jacket is an energizing core made from an elastomer, most commonly silicone or FKM.

This core provides the rubber-like elasticity and "memory" required for the O-ring to compress, conform to the sealing surfaces, and maintain a consistent force.

Key Applications and Use Cases

The unique construction of these O-rings makes them the default choice in several specific scenarios where performance and reliability are non-negotiable.

Sealing Aggressive Chemicals

The primary driver for using an encapsulated O-ring is its near-universal chemical compatibility. The inert Teflon jacket can handle a wide range of acids, solvents, and bases that would cause standard O-rings to swell, degrade, or dissolve.

This makes them essential for pumps, valves, and flanges in chemical processing plants.

Ensuring High-Purity Systems

In pharmaceutical and semiconductor manufacturing, preventing contamination is paramount. The non-stick, low-friction surface of Teflon prevents material from sticking to the seal.

More importantly, the complete encapsulation of the elastomer core prevents it from leaching or outgassing particles into the high-purity fluid stream.

Handling High-Temperature Services

While the elastomer core has its own temperature limits, the Teflon jacket provides an additional thermal barrier. This allows the seal to function effectively in environments that exceed the operational range of many standard elastomers.

Understanding the Trade-offs and Limitations

While highly effective, encapsulated O-rings are a specialized component, not a universal replacement for all O-rings. Understanding their limitations is key to using them correctly.

Designed for Static Sealing

These O-rings are intended for static applications, such as face seals or flange gaskets, where there is no movement between the sealing surfaces.

The relative stiffness and friction characteristics of the Teflon jacket make it less suitable for dynamic applications like rotating shafts or reciprocating pistons, where it can be prone to premature wear.

Higher Compression Set

The rigidity of the Teflon jacket means that once compressed, the O-ring does not spring back to its original shape as effectively as a pure elastomer O-ring.

This higher "compression set" means they are less forgiving of poorly machined surfaces or frequent assembly/disassembly cycles.

Installation Requires Care

The stiffness of the Teflon jacket can make installation more difficult than with a standard, flexible O-ring. Stretching the O-ring over a shaft or into a groove requires careful technique to avoid kinking or damaging the jacket, which would compromise the seal.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the component's strengths to your primary goal.

- If your primary focus is sealing aggressive chemicals: The encapsulated O-ring is almost certainly the correct choice due to its inert Teflon jacket.

- If your primary focus is high-purity fluid handling: This design is ideal, as it prevents contamination by isolating the elastomer core from the process media.

- If your primary focus is a dynamic seal (e.g., a rotating shaft): You should exercise caution and likely specify a different type of seal, such as a spring-energized PTFE seal or a standard high-performance elastomer O-ring.

Choosing the right seal is about understanding the specific demands of the application and selecting the component designed to meet them.

Summary Table:

| Feature | Benefit |

|---|---|

| Teflon Jacket (FEP/PFA) | Superior chemical inertness and high-temperature resistance. |

| Elastomer Core (Silicone/FKM) | Provides flexibility and sealing force for a reliable static seal. |

| Primary Application | Static sealing in chemical processing, semiconductor, pharmaceutical, and aerospace industries. |

| Key Advantage | Isolates the core from media, preventing contamination and degradation. |

Need a reliable seal for demanding conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom Teflon encapsulated O-rings. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our precision production ensures a perfect seal for your most critical applications.

Contact our experts today to discuss your specific requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments