The most effective way to manage thermal expansion during PTFE machining is to implement a multi-faceted strategy that minimizes heat generation, actively removes any heat that is created, and reduces mechanical stress on the workpiece. This involves a careful combination of sharp tooling, optimized cutting parameters, generous coolant application, and proper workholding techniques. Success depends not on a single trick, but on a holistic approach that respects the material's unique properties.

The core challenge with machining PTFE is its high coefficient of thermal expansion combined with its low thermal conductivity. This means it expands significantly when heated, and that heat remains localized, causing unpredictable deformation and making it difficult to hold tight tolerances.

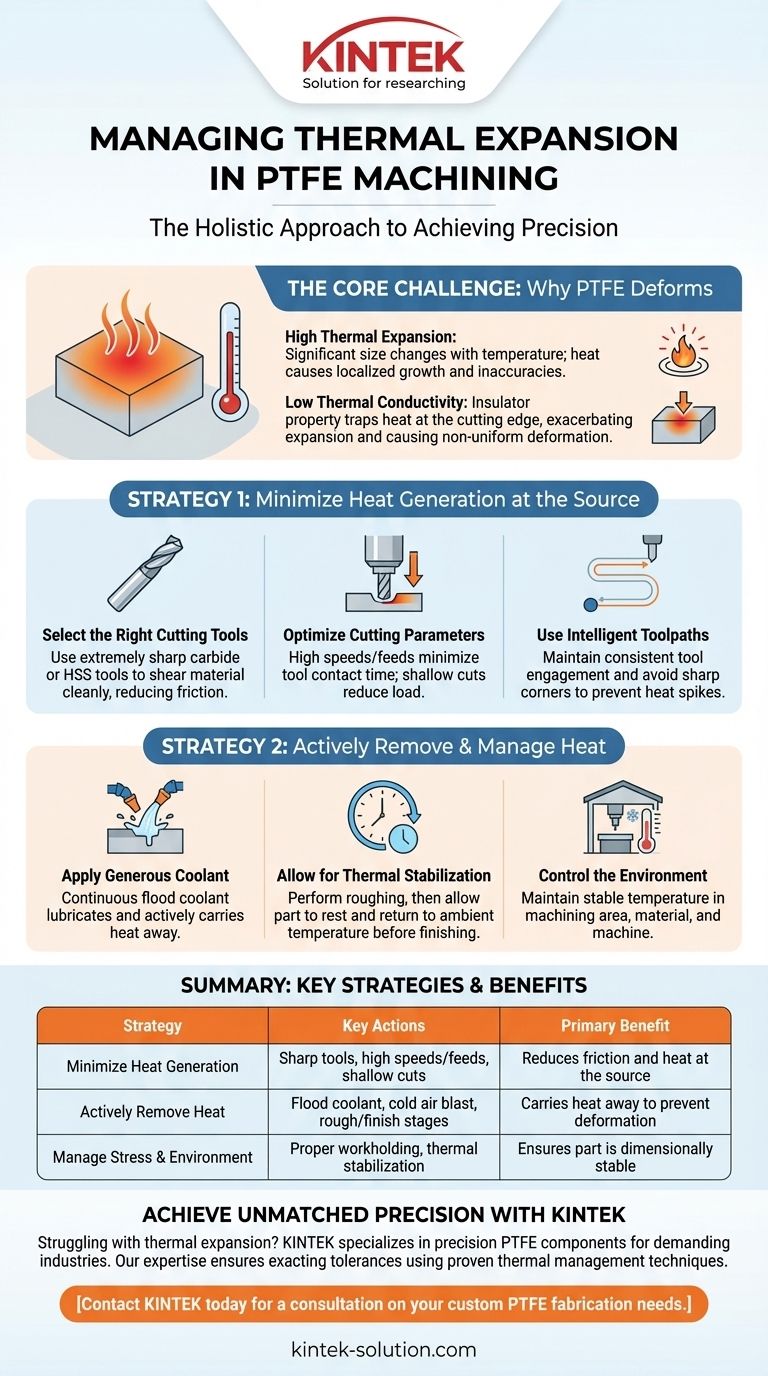

The Core Challenge: Why PTFE Deforms

PTFE's properties create a unique set of machining challenges. Understanding the "why" behind its behavior is the first step toward controlling it.

High Thermal Expansion

PTFE expands and contracts with temperature changes far more than metals or other plastics. Heat generated by a cutting tool will cause the material in the immediate area to grow, leading to an inaccurate cut. When the part cools, it will shrink to a dimension different from what was intended.

Low Thermal Conductivity

Unlike metals that quickly dissipate heat throughout the material, PTFE acts as an insulator. Heat generated at the cutting edge doesn't spread out; it concentrates in a small area. This localized heat buildup exacerbates the thermal expansion problem, causing focused, non-uniform deformation.

Strategy 1: Minimize Heat Generation at the Source

The most effective approach is to prevent heat from building up in the first place. This is achieved by reducing friction and stress at the cutting point.

Select the Right Cutting Tools

The tool is your first line of defense. A poor tool choice will generate excessive friction and heat, regardless of your machine settings.

Use extremely sharp cutting tools, preferably made from carbide or high-speed steel (HSS). A sharp edge shears the material cleanly rather than plowing through it, which dramatically reduces friction. Polished flutes further aid in smooth chip evacuation.

Optimize Cutting Parameters

Your speeds and feeds directly control the energy—and therefore heat—put into the part.

Aim for high cutting speeds (200-1000 m/min) paired with high feed rates. This combination allows the tool to move through the material quickly, minimizing the time any single point is subjected to friction. Conversely, a tool that spins quickly but moves forward slowly (low feed rate) will rub and generate significant heat.

Employ a shallow depth of cut. This reduces the amount of material being removed at any given moment, lowering the load on the tool and minimizing heat generation.

Use Intelligent Toolpaths

How the tool moves is just as important as how fast it moves. Modern CAM software allows for toolpaths that prevent heat spikes.

Utilize strategies that maintain a consistent tool engagement, such as trochoidal milling. Avoid sharp corners where the tool can dwell and build up heat.

Strategy 2: Actively Remove and Manage Heat

Because some heat generation is unavoidable, the second part of the strategy is to remove it from the workpiece and tool as efficiently as possible.

Apply Generous Coolant

Flood coolant is highly effective for PTFE. A continuous flow of coolant serves two critical purposes: it lubricates the cutting interface to reduce friction and, more importantly, it actively carries heat away from both the tool and the workpiece before it can cause expansion.

Allow for Thermal Stabilization

For parts requiring the highest precision, machining in stages is a proven technique.

Perform a "roughing" pass to remove the bulk of the material. Then, allow the part to rest and return to ambient temperature before performing a light, final "finishing" pass. This ensures the final cut is made on a dimensionally stable part.

Control the Environment

In applications with extreme tolerance requirements, the temperature of the entire machining environment should be stable. A temperature-controlled shop ensures the raw material, the machine, and the final part are all measured and cut in a consistent thermal state.

Understanding the Trade-offs

Mastering PTFE requires acknowledging its inherent limitations and the compromises involved in machining it.

Speed vs. Precision

While high speeds can be effective, pushing for maximum material removal rates will always increase the risk of thermal deformation. For critical features, slowing down and using lighter cuts will almost always yield a more accurate result.

Workholding vs. Part Integrity

PTFE is soft and easily compressed. Over-tightening a vise or clamps will deform the material before a cut is even made. This pre-loaded stress, combined with thermal expansion, can lead to severe inaccuracies. Use low, evenly distributed clamping pressure.

Coolant vs. Contamination

For medical or food-grade applications, liquid coolants may not be permissible. In these cases, a cold air blast is an excellent alternative. It provides effective cooling without introducing contaminants. However, it offers less lubrication, so sharp tools and optimized parameters become even more critical.

Making the Right Choice for Your Goal

The ideal strategy depends entirely on the requirements of the final part. Use these principles to guide your approach.

- If your primary focus is achieving the tightest possible tolerances: Prioritize a two-stage machining process (rough, cool, finish) and use generous coolant in a temperature-controlled environment.

- If your primary focus is production efficiency: Use extremely sharp, coated carbide tools with high-pressure flood coolant to maximize cutting speeds and chip evacuation.

- If your primary focus is machining for a sensitive (e.g., medical) application: Opt for dry machining using a cold air blast for cooling, and accept that cycle times will be longer to ensure part integrity.

Success with PTFE comes from treating it not as a difficult material, but as a unique one that demands a thoughtful and deliberate machining strategy.

Summary Table:

| Strategy | Key Actions | Primary Benefit |

|---|---|---|

| Minimize Heat Generation | Sharp carbide tools, high speeds/feeds, shallow cuts | Reduces friction and heat at the source |

| Actively Remove Heat | Flood coolant, cold air blast, rough/finish stages | Carries heat away to prevent deformation |

| Manage Stress & Environment | Proper workholding, thermal stabilization | Ensures part is dimensionally stable during and after machining |

Achieve Unmatched Precision in Your PTFE Components

Struggling with thermal expansion and dimensional instability in your machined PTFE parts? The strategies outlined above are core to our manufacturing process at KINTEK. We specialize in precision machining of PTFE components—from custom seals and liners to complex labware—for the most demanding industries, including semiconductor, medical, and laboratory applications.

Our expertise ensures your prototypes and high-volume orders are produced with the exacting tolerances you require. Let us apply our proven thermal management techniques to your project.

Contact KINTEK today for a consultation on your custom PTFE fabrication needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs