In short, PTFE expansion bellows are crucial because they act as protective shock absorbers for industrial piping systems. They are specifically engineered flexible connectors that absorb the destructive forces of thermal expansion, vibration, and misalignment, thereby preventing costly cracks, leaks, and catastrophic system failures.

The core function of a PTFE expansion bellow is to enhance system reliability and safety. By isolating rigid pipelines from the inevitable stresses of industrial operations, it extends the life of the entire system, reduces maintenance costs, and prevents unscheduled downtime.

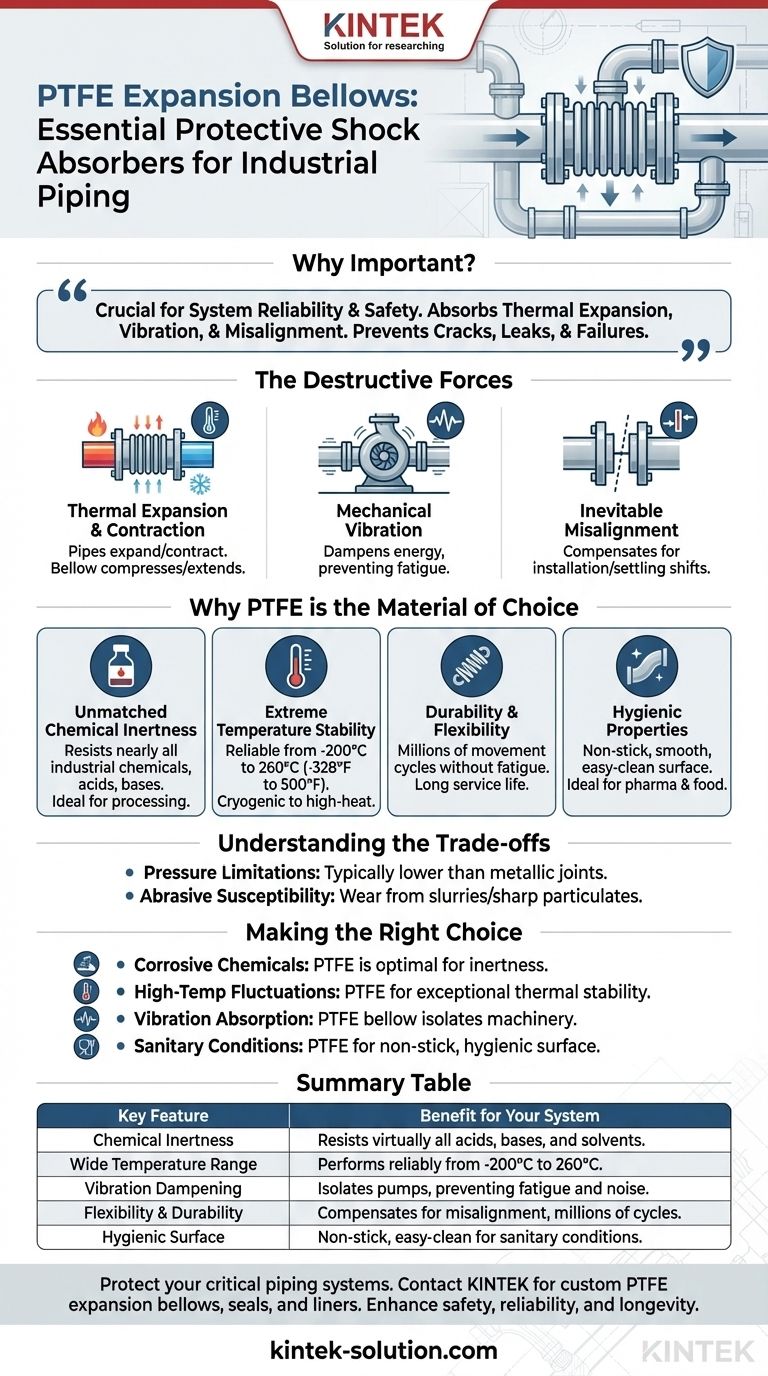

The Destructive Forces in Every Piping System

Industrial piping is rarely static. Three primary forces constantly exert stress on pipes, anchors, and connected equipment. A PTFE bellow is designed to manage all three.

Thermal Expansion and Contraction

Pipes expand when heated and contract when cooled. Over long distances, this movement generates immense force that can buckle pipes or break connections. A bellow compresses and extends to safely absorb this thermal movement.

Mechanical Vibration

Pumps, motors, and compressors transmit constant vibrations through the piping system. This energy can lead to metal fatigue and eventual failure. A PTFE bellow acts as a vibration dampener, isolating the source from the rest of the system.

Inevitable Misalignment

Achieving perfect alignment between two pieces of equipment or pipe runs is difficult and can shift over time as foundations settle. A bellow's flexibility compensates for initial and subsequent misalignment, preventing stress on flanges and joints.

Why PTFE is the Material of Choice

While expansion joints can be made from metal or rubber, Polytetrafluoroethylene (PTFE) offers a unique combination of properties that make it superior for demanding applications.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents. This makes it the default choice for chemical processing, pharmaceutical, and food-grade applications where corrosion or contamination is a primary concern.

Extreme Temperature Stability

PTFE performs reliably across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). This allows it to function in cryogenic services as well as high-temperature chemical processes without losing its structural integrity.

Durability and Flexibility

The material's inherent flexibility allows it to cycle through millions of movements without fatiguing. This ensures a long service life and high system reliability, directly reducing the need for frequent replacements and maintenance.

Hygienic Properties

PTFE has a non-stick, smooth surface that resists buildup and is easy to clean. This makes it ideal for sanitary systems in the pharmaceutical and food and beverage industries where preventing contamination is critical.

Understanding the Trade-offs

While highly effective, PTFE bellows are not a universal solution. Understanding their limitations is key to proper application.

Pressure Limitations

Compared to robust metallic expansion joints, standard PTFE bellows typically have lower pressure ratings. For extremely high-pressure systems, a specialized or alternative type of joint may be necessary.

Susceptibility to Abrasives

Although chemically inert, the surface of PTFE can be worn down by highly abrasive slurries or media with sharp particulates. In these specific cases, other materials might offer better longevity.

Requirement for Proper Anchoring

Like any expansion joint, a PTFE bellow is only effective if the surrounding pipeline is properly anchored and guided. Without correct installation, the bellow itself can be damaged by uncontrolled pipe movement.

Making the Right Choice for Your System

Selecting the right component depends entirely on the primary challenge your system faces.

- If your primary focus is handling corrosive chemicals: PTFE is the optimal choice due to its near-universal chemical inertness, ensuring both system and product purity.

- If your primary focus is managing high-temperature fluctuations: The exceptional thermal stability of PTFE makes it a reliable solution for absorbing expansion and contraction in heated or cooled systems.

- If your primary focus is absorbing vibration: A PTFE bellow's flexibility effectively isolates machinery from the piping, preventing fatigue damage and reducing operational noise.

- If your primary focus is maintaining sanitary conditions: PTFE's non-stick and hygienic surface makes it the superior option for pharmaceutical and food-grade applications.

Ultimately, integrating PTFE expansion bellows is a strategic investment in the long-term reliability and safety of your critical industrial infrastructure.

Summary Table:

| Key Feature | Benefit for Your System |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, ideal for corrosive processes. |

| Wide Temperature Range | Performs reliably from -200°C to 260°C (-328°F to 500°F). |

| Vibration Dampening | Isolates pumps and equipment, preventing metal fatigue and noise. |

| Flexibility & Durability | Compensates for misalignment and handles millions of movement cycles. |

| Hygienic Surface | Non-stick, easy-clean properties ensure sanitary conditions for pharma & food. |

Protect your critical piping systems from costly downtime and damage.

At KINTEK, we specialize in manufacturing high-precision, custom-fabricated PTFE components, including expansion bellows, seals, and liners. Whether you need a prototype for a new application or high-volume orders for semiconductor, medical, laboratory, or industrial use, our expertise ensures a reliable solution tailored to your specific chemical, temperature, and pressure requirements.

Contact KINTEK today for a consultation on how our PTFE expansion bellows can enhance the safety, reliability, and longevity of your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the advantages of Teflon bearings? Low-Friction, Maintenance-Free Performance for Demanding Environments

- What are the main benefits of Teflon packing? Achieve Superior Sealing for Demanding Applications

- How does PTFE coating enhance corrosion resistance in fasteners? Achieve Unmatched Protection in Harsh Environments

- What are important installation tips for PTFE butterfly valves? Ensure a Leak-Free, Long-Lasting Seal

- What role do PTFE lined ball valves play in natural gas transmission? Ensuring Safety and Reliability

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- How do PTFE rotary shaft seals achieve their sealing performance? Engineered for Extreme Conditions

- What are some medical applications of PTFE energized seals? Ensuring Reliability and Purity in Medical Devices