At its core, Teflon (PTFE) packing is specified for its exceptional chemical resistance, extremely low friction, and high-temperature stability. These three properties make it one of the most reliable and versatile sealing materials for demanding industrial applications, from chemical processing pumps to food-grade mixers.

The true value of Teflon packing isn't just its individual properties, but how they combine to solve a deeper problem: creating a durable, low-maintenance seal that protects equipment, prevents leaks, and reduces operational costs in challenging environments.

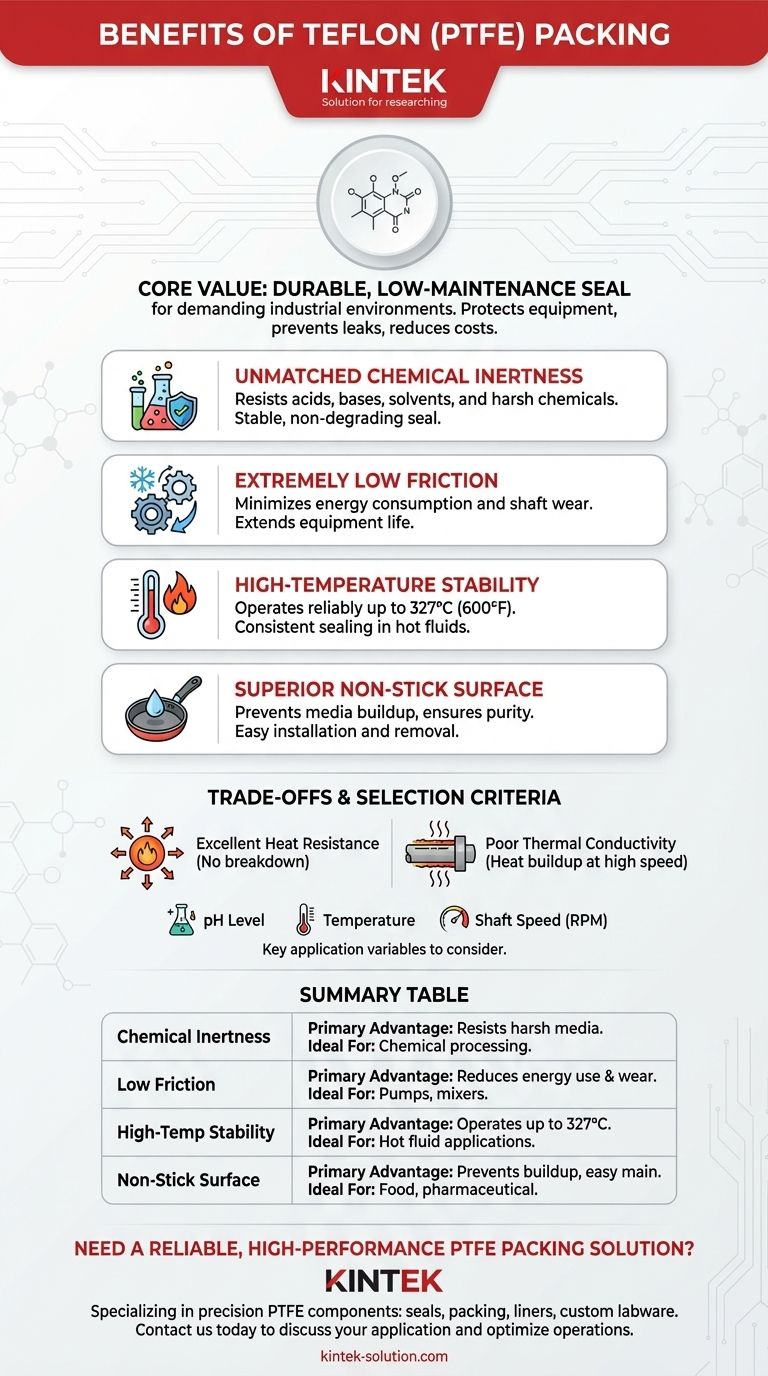

The Core Technical Advantages of PTFE Packing

The benefits of PTFE packing stem directly from the unique molecular structure of polytetrafluoroethylene. Understanding these foundational properties explains why it is so widely adopted.

Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It remains stable and effective when exposed to a vast range of aggressive media, including concentrated acids, bases, solvents, and other harsh chemicals.

This inertness ensures the packing will not degrade, swell, or fail, providing a secure and long-lasting seal in applications where other materials would quickly break down. This makes it a default choice for equipment handling substances like sulfuric acid or nitric acid.

Extremely Low Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This "slipperiness" is a significant advantage in rotating equipment like pumps and mixers.

A low-friction packing minimizes drag on the shaft, which directly translates to reduced energy consumption. More importantly, it significantly reduces wear and scoring on expensive equipment shafts, preventing costly damage and extending the operational life of the machinery.

High-Temperature Stability

PTFE packing can operate reliably across a wide temperature range, with some variants withstanding continuous service temperatures up to 327°C (over 600°F).

This allows it to be used in hot fluid applications without melting, hardening, or losing its sealing integrity. It provides a consistent, predictable sealing force even as operational temperatures fluctuate.

Superior Non-Stick Surface

The famous non-stick quality of Teflon is also a key benefit in gland packing. This property prevents process media from sticking to and building up on the packing material, which is critical in food processing and pharmaceutical applications to ensure purity.

This same property also makes the packing easier to install and, crucially, easier to remove during maintenance, reducing labor time and the risk of damaging the stuffing box.

Understanding the Trade-offs and Selection Criteria

While PTFE offers powerful advantages, no single material is a universal solution. A proper technical evaluation requires understanding its limitations and the specific demands of the application.

Heat Dissipation vs. Heat Resistance

This is the most critical trade-off to understand. While PTFE has excellent heat resistance (it doesn't break down at high temperatures), it is a poor thermal conductor. It does not dissipate frictional heat away from the shaft effectively.

In very high-speed shaft applications, this can lead to heat buildup that can damage the shaft or the packing itself. In these cases, a material like graphite, which has excellent thermal conductivity, may be a better choice.

Considering the Application Variables

The decision to use PTFE packing must be based on a clear analysis of the operating conditions. Key factors to evaluate include:

- pH Level: PTFE excels across the entire pH scale.

- Temperature: Ensure the expected operating temperature is within the packing's specified range.

- Shaft Speed (RPM): This is critical. For lower-speed mixers and agitators, PTFE is ideal. For high-speed pumps, you must account for potential heat buildup.

Making the Right Choice for Your Application

Selecting the correct packing is about aligning the material's strengths with your primary operational goal.

- If your primary focus is sealing aggressive chemicals: PTFE is an industry-standard choice due to its near-universal chemical inertness, ensuring seal integrity and safety.

- If your primary focus is reducing long-term maintenance: PTFE's durability and low-friction nature lead to longer service life and less wear on equipment, lowering the total cost of ownership.

- If your primary focus is high-speed rotation: You must carefully weigh PTFE's benefits against its poor heat dissipation, potentially considering graphite-impregnated PTFE or a full graphite packing instead.

Choosing the right packing material is a technical decision that directly impacts equipment reliability and operational efficiency.

Summary Table:

| Key Benefit | Primary Advantage | Ideal For |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents | Chemical processing, harsh media |

| Low Friction | Reduces energy use & shaft wear | Pumps, mixers, agitators |

| High-Temperature Stability | Operates up to 327°C (600°F) | Hot fluid applications |

| Non-Stick Surface | Prevents buildup, easy maintenance | Food, pharmaceutical, purity-critical uses |

Need a reliable, high-performance PTFE packing solution?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, packing, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a sealing solution that enhances equipment longevity, reduces maintenance costs, and operates flawlessly in your specific environment.

Whether you require a prototype or high-volume production, we deliver quality and durability tailored to your needs. Contact us today to discuss your application and get a solution that protects your equipment and optimizes your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is PTFE packing and what are its primary characteristics? Master Sealing for Extreme Conditions

- What are the key product features of Teflon lip seals? Engineered for Extreme Performance

- Why are extruded PTFE rods popular in plumbing systems? Superior Chemical & Thermal Resistance

- What factors should be considered when selecting a PTFE expansion joint? Ensure System Integrity and Safety

- Why is PTFE the preferred material for bellows and diaphragms? Unmatched Chemical, Thermal, and Mechanical Stability

- What are the advantages of using PTFE material for machine parts? Achieve Peak Performance in Demanding Environments

- What environmental benefits do PTFE expansion joints provide? Achieve Sustainability and Compliance

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech