At its core, PTFE packing is a high-performance sealing material made from the synthetic fluoropolymer polytetrafluoroethylene. It is specifically engineered to prevent leaks in demanding industrial equipment like pumps and valves. Its value stems from a unique combination of extreme chemical resistance, an incredibly low-friction surface, and stability across a vast temperature range.

The essential takeaway is that PTFE packing is not a general-purpose sealant; it is a specialized solution for extreme environments. It is the material of choice when equipment must operate reliably in the presence of harsh chemicals, at cryogenic or high temperatures, or where minimizing friction and wear is critical.

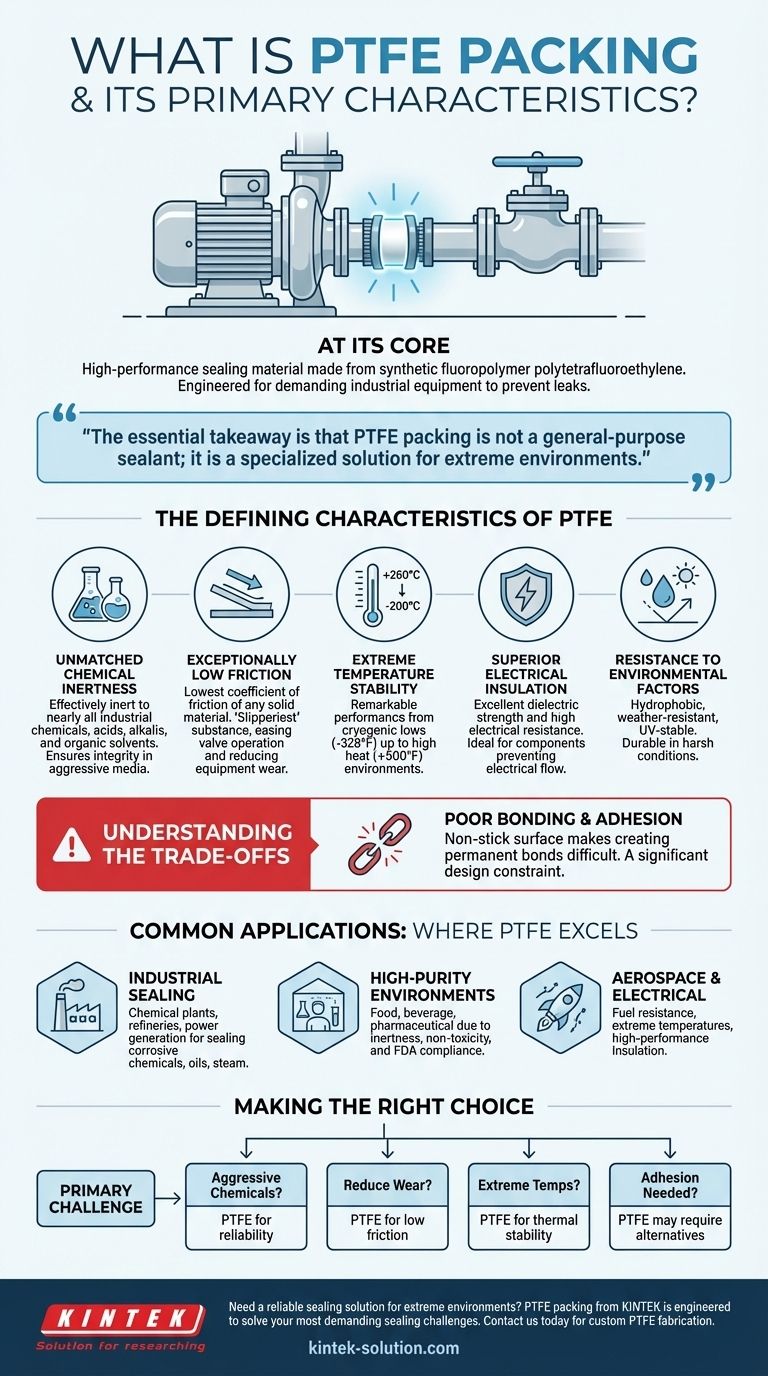

The Defining Characteristics of PTFE

To understand where and why to use PTFE packing, we must analyze its fundamental properties. These characteristics are not just technical data points; they are the reasons it solves problems that other materials cannot.

Unmatched Chemical Inertness

PTFE is renowned for being one of the most chemically resistant materials known. It is effectively inert to nearly all industrial chemicals, including strong acids, alkalis, corrosive substances, and organic solvents.

This high level of resistance ensures the packing's integrity and prevents it from degrading, even when sealing the most aggressive media. The only notable exceptions are molten alkali metals and hot fluorine gas.

Exceptionally Low Friction

PTFE has the lowest coefficient of friction of any known solid material, making it one of the "slipperiest" substances available. This results in a non-stick, non-adhesive surface.

In a practical sense, this means valves are easier to operate, and there is significantly less wear and tear on rotating shafts in pumps. The packing protects the equipment it is designed to seal.

Extreme Temperature Stability

This material demonstrates remarkable performance across an exceptionally wide thermal range. It maintains its properties from cryogenic lows of around -200°C (-328°F) up to high-heat environments of +260°C (500°F).

This stability allows it to be specified for applications ranging from liquid natural gas processing to high-temperature steam systems without failure.

Superior Electrical Insulation

Beyond its mechanical properties, PTFE is an excellent electrical insulator. It possesses high dielectric strength and high electrical resistance.

This characteristic makes it suitable for applications where a component must provide a reliable seal while also preventing the flow of electrical current.

Resistance to Environmental Factors

PTFE is hydrophobic, meaning it does not absorb water. It is also highly resistant to degradation from weather, corrosion, and UV light. This durability ensures a long service life even in exposed or harsh operating conditions.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's properties are exceptional, they also create inherent limitations that are critical to understand for proper application.

Poor Bonding and Adhesion

The same non-stick, low-friction surface that makes PTFE so valuable also makes it very difficult to bond to other materials. Its non-adhesive nature means that creating a permanent bond using conventional glues or cements is often not feasible.

This is a key consideration in designs where the packing might need to be affixed to another component.

Common Applications: Where PTFE Excels

The unique combination of PTFE's properties makes it indispensable in several key markets.

Industrial Sealing

This is the primary application for PTFE packing. It is used extensively in chemical processing plants, refineries, and power generation facilities to seal pumps, valves, and agitators that handle corrosive chemicals, fuel gases, oils, and steam.

High-Purity Environments

Because PTFE is inert, non-toxic, and can meet FDA requirements, it is widely used in the food, beverage, and pharmaceutical industries. It will not contaminate the product it comes into contact with, ensuring purity.

Aerospace and Electrical

In aerospace, its stability at extreme temperatures and resistance to corrosive fuels are invaluable. In the electrical market, it serves as a high-performance insulator for wiring and components where reliability is paramount.

Making the Right Choice for Your Application

Selecting the correct sealing material requires matching the material's strengths to your primary operational challenge.

- If your primary focus is sealing against aggressive chemicals: PTFE's unparalleled chemical inertness makes it the default choice for reliability.

- If your primary focus is reducing mechanical wear and operating force: Its exceptionally low-friction surface will protect equipment and improve efficiency.

- If your primary focus is performance across extreme temperatures: PTFE's stability from cryogenic cold to high heat is unmatched by most sealing polymers.

- If your primary focus involves adhesion or bonding to other surfaces: Be aware that PTFE's non-stick nature is a significant design constraint that may require alternative solutions.

By understanding these core characteristics, you can confidently specify PTFE packing for the most demanding sealing challenges.

Summary Table:

| Characteristic | Benefit |

|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and solvents. |

| Low Friction | Reduces wear on equipment, eases valve operation. |

| Temperature Stability | Performs from -200°C to +260°C (-328°F to 500°F). |

| Electrical Insulation | Excellent dielectric strength and high electrical resistance. |

| Environmental Resistance | Hydrophobic, weather-resistant, and UV-stable for long life. |

Need a reliable sealing solution for extreme environments?

PTFE packing from KINTEK is engineered to solve your most demanding sealing challenges. We manufacture high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require prototypes or high-volume production, our expertise ensures a perfect fit for your application, delivering unmatched chemical resistance, thermal stability, and reduced friction to protect your equipment and enhance operational efficiency.

Contact KINTEK today to discuss your specific requirements and get a quote for custom PTFE fabrication.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE gaskets suitable for aerospace applications? Unmatched Reliability in Extreme Conditions

- What are the advantages of Teflon-encapsulated O-Rings? Superior Sealing for Demanding Industrial Applications

- What are the benefits of PTFE backup rings? Enhance Seal Life in High-Pressure Systems

- Why is ePTFE gasket material suitable for high-temperature applications? Unlock Reliable Sealing Under Extreme Heat

- What environmental concerns are associated with Teflon packing? The Hidden Cost of a Non-Biodegradable Seal

- What are the main advantages of PTFE washers in industrial applications? Unlock Superior Chemical & Thermal Performance

- What are the primary applications of PTFE-lined ball valves? Control Corrosive & High-Purity Fluids

- What are the primary properties of PTFE rod? Unlock Extreme Performance for Demanding Applications