In short, the primary advantages of PTFE are its extremely low coefficient of friction, exceptional chemical resistance, and stability across a wide range of temperatures. These core properties make Polytetrafluoroethylene (PTFE) a uniquely versatile material for demanding mechanical, electrical, and chemical applications.

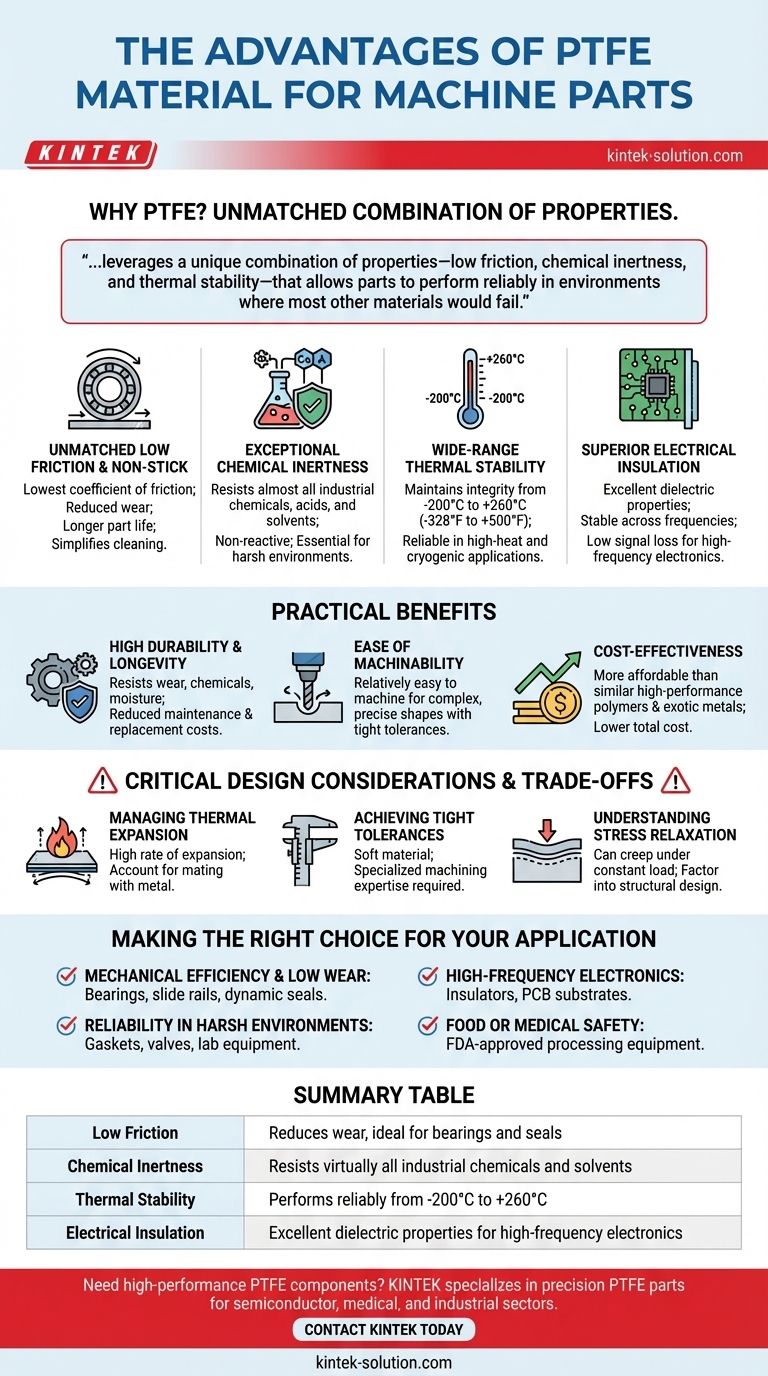

The decision to use PTFE for a machine part is rarely about a single benefit. It is about leveraging a unique combination of properties—low friction, chemical inertness, and thermal stability—that allows parts to perform reliably in environments where most other materials would fail.

The Core Properties Defining PTFE's Advantage

PTFE's value comes from a set of intrinsic material characteristics. Understanding these properties is key to knowing when and where to specify it for a component.

Unmatched Low Friction and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material. This makes it an ideal choice for components that must slide or rotate with minimal resistance.

This property directly translates to reduced wear and longer part life in applications like bearings, seals, and slide plates. Its non-stick nature also simplifies cleaning, which is critical in food processing and medical applications.

Exceptional Chemical Inertness

This material is highly resistant to almost all industrial chemicals, acids, and solvents. It is fundamentally chemically inert and non-reactive.

This makes PTFE essential for parts used in chemical processing, laboratory equipment, and any environment with exposure to aggressive substances.

Wide-Range Thermal Stability

PTFE parts maintain their integrity and performance across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows PTFE components like gaskets, seals, and valves to operate reliably in high-heat automotive applications or cryogenic aerospace systems.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with outstanding dielectric properties. Its resistance to electrical current is high, and it maintains a stable dielectric constant across a wide range of frequencies.

This characteristic is crucial for high-frequency electronics, such as in RF and high-speed digital circuit boards (PCBs), where it ensures low signal loss and reliable performance.

Practical Benefits in Application

Beyond its core scientific properties, PTFE offers tangible engineering and economic benefits that drive its adoption.

High Durability and Longevity

The combination of wear resistance, chemical stability, and moisture resistance results in components that are incredibly durable and long-lasting, even in challenging service conditions. This leads to reduced maintenance and replacement costs over the component's lifespan.

Ease of Machinability

Despite its high performance, PTFE is relatively easy to machine into complex and precise shapes. This allows for the efficient production of custom parts with tight tolerances.

Cost-Effectiveness

When compared to other high-performance polymers and exotic metals that might offer similar performance in one or two categories, PTFE is often a more affordable solution. Its ease of machining further contributes to a lower total cost for the finished part.

Critical Design Considerations and Trade-offs

While PTFE is a remarkable material, its successful implementation requires an understanding of its limitations. A trusted advisor must point out that no material is perfect for every situation.

Managing Thermal Expansion

PTFE has a relatively high rate of thermal expansion and contraction. Engineers must account for this behavior in their designs, especially when mating PTFE parts with metal components, to avoid failure due to temperature fluctuations.

Achieving Tight Tolerances

While machinable, PTFE is a relatively soft material. Achieving and holding extremely tight tolerances can be more challenging than with rigid metals, requiring specialized machining expertise.

Understanding Stress Relaxation

Under a constant load, PTFE can exhibit "creep" or stress relaxation, meaning it may slowly deform over time. This behavior must be factored into the design of structural components or high-pressure seals to ensure long-term integrity.

Making the Right Choice for Your Application

To select PTFE effectively, align its specific strengths with the primary demands of your project.

- If your primary focus is mechanical efficiency and low wear: PTFE is an ideal choice for bearings, slide rails, and dynamic seals where minimizing friction is the top priority.

- If your primary focus is reliability in harsh environments: Use PTFE for gaskets, valves, and laboratory equipment that will be exposed to aggressive chemicals or extreme temperatures.

- If your primary focus is high-frequency electronics: Specify PTFE for insulators and PCB substrates to ensure low signal loss and stable electrical performance.

- If your primary focus is food or medical safety: Its FDA-approved status and non-stick, inert properties make it a safe and reliable choice for processing equipment and medical device components.

Ultimately, choosing PTFE is an informed decision to prioritize performance and reliability in conditions that push material limits.

Summary Table:

| Core Property | Key Advantage |

|---|---|

| Low Friction | Reduces wear, ideal for bearings and seals |

| Chemical Inertness | Resists virtually all industrial chemicals and solvents |

| Thermal Stability | Performs reliably from -200°C to +260°C |

| Electrical Insulation | Excellent dielectric properties for high-frequency electronics |

Need high-performance PTFE components for your application?

KINTEK specializes in manufacturing precision PTFE parts—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We deliver the durability and reliability your demanding applications require, from prototypes to high-volume production.

Contact KINTEK today to discuss your custom PTFE fabrication needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments