At its core, the popularity of extruded Polytetrafluoroethylene (PTFE) rods in plumbing is due to a rare combination of chemical inertness, thermal stability, and low-friction properties. This material isn't chosen for its structural strength like steel, but for its exceptional ability to resist degradation. This ensures long-term reliability and integrity in systems that handle everything from potable water to aggressive industrial chemicals.

The fundamental reason for choosing PTFE in plumbing is risk mitigation. Its inherent resistance to chemical corrosion, high temperatures, and material degradation directly translates to safer, more durable, and lower-maintenance fluid handling systems, preventing costly failures and contamination.

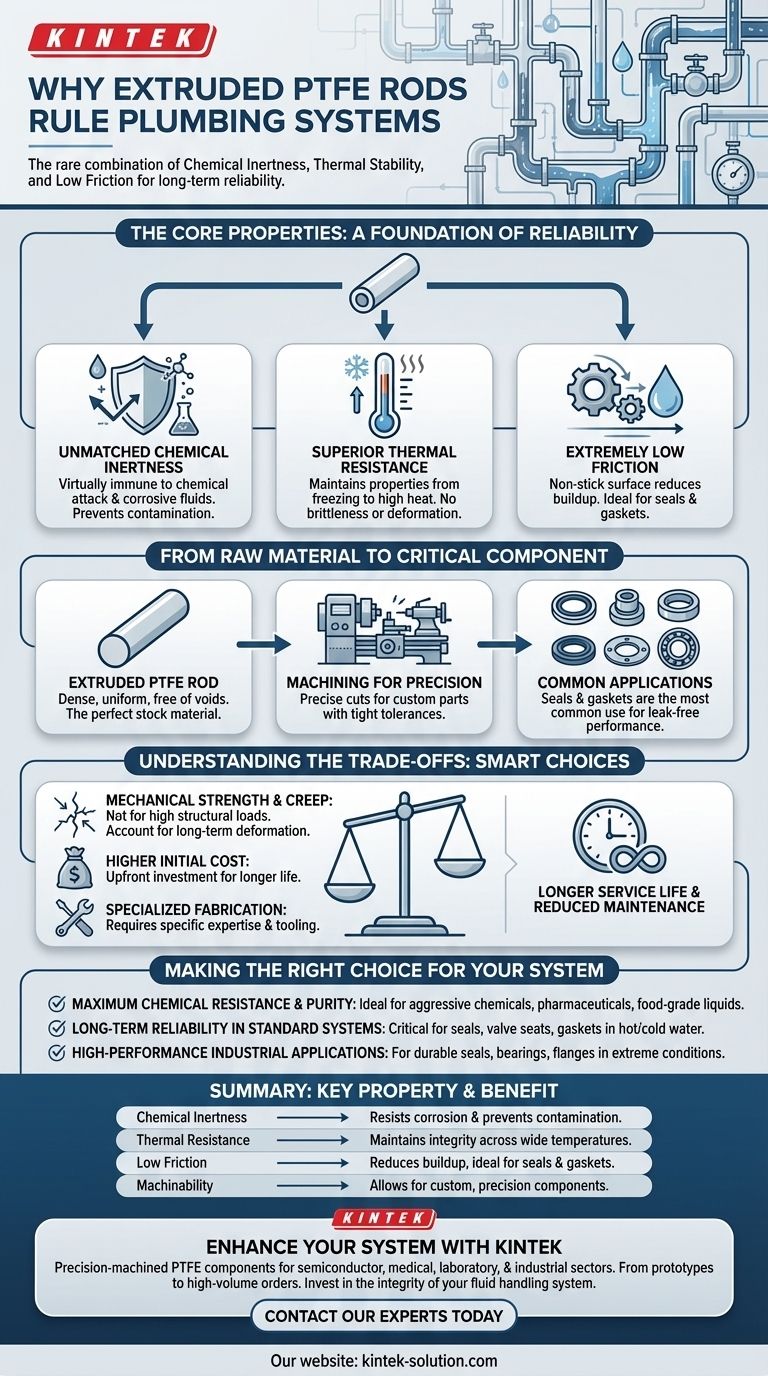

The Core Properties Driving PTFE Adoption

To understand why PTFE is a go-to material, we must look at its three primary characteristics. These properties work together to create a material uniquely suited for the demanding environment inside a plumbing system.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It is virtually immune to attack from the vast majority of chemicals and corrosive fluids.

This inertness is critical for preventing the material itself from breaking down, which would otherwise lead to leaks. It also ensures that the fluid being transported remains pure and uncontaminated by the piping components.

Superior Thermal Resistance

Plumbing systems are often subject to significant temperature fluctuations, from cold mains water to hot industrial process fluids.

PTFE maintains its key properties across a very wide temperature range without becoming brittle or losing its shape. This stability prevents failures that could occur with lesser materials when exposed to thermal cycling.

Extremely Low Friction

PTFE has an exceptionally low coefficient of friction, which gives it a "non-stick" surface. This property is vital for two reasons.

First, it reduces the tendency for scale, biofilm, or other deposits to build up on the interior surfaces of components, ensuring consistent flow. Second, it makes PTFE an ideal material for seals and gaskets, where parts must press together tightly without sticking or wearing out quickly.

From Raw Material to Critical Component

Extruded PTFE rods are a versatile starting point, but they are rarely used in their raw form. Their value is realized when they are precisely fabricated into specialized components that solve specific plumbing challenges.

The Role of Extrusion

The extrusion process creates a dense, uniform, and solid rod of PTFE. This provides a consistent, high-quality stock material that is free of voids or imperfections, which is essential for machining reliable, pressure-tight parts.

Machining for Precision

The true advantage of PTFE rods is their machinability. They can be precisely cut, drilled, and shaped on a lathe or mill to create custom components.

This allows for the manufacturing of parts with tight tolerances, such as valve seats, seals, gaskets, and bearings, tailored to specific applications.

Common Applications: Seals and Gaskets

The most common use for machined PTFE in plumbing is in creating seals and gaskets. Its ability to deform slightly under pressure creates a tight seal, while its chemical and thermal resistance ensures that seal remains intact for years without degrading.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging the limitations and practical considerations of using PTFE.

Mechanical Strength and Creep

PTFE is a relatively soft material compared to metals. It is not suitable for applications requiring high structural or tensile strength. It can also be subject to "creep," a slow deformation under sustained pressure, which must be accounted for in component design.

Higher Initial Cost

Components machined from PTFE typically have a higher upfront cost than parts made from common plastics like PVC or traditional materials like rubber. The investment is justified by a longer service life and significantly lower maintenance and replacement costs over time.

Specialized Fabrication

While machinable, working with PTFE requires specific knowledge and tooling to achieve precision without melting or damaging the material. This is not a material that can be easily fabricated in the field.

Making the Right Choice for Your System

Selecting the right material is about matching its properties to your primary goal. PTFE's strengths make it the clear choice for applications where reliability and purity are paramount.

- If your primary focus is maximum chemical resistance and purity: PTFE is the default choice for systems handling aggressive chemicals, pharmaceuticals, or food-grade liquids where preventing contamination is non-negotiable.

- If your primary focus is long-term reliability in standard systems: Use machined PTFE for critical seals, valve seats, and gaskets in hot or cold water systems to prevent leaks and avoid the frequent maintenance cycles associated with lesser materials.

- If your primary focus is high-performance industrial applications: Custom-machined PTFE is ideal for creating durable, low-friction seals, bearings, and flanges in systems involving high temperatures and corrosive media.

Ultimately, selecting PTFE is an investment in the long-term operational integrity and safety of your fluid handling system.

Summary Table:

| Key Property | Benefit in Plumbing Systems |

|---|---|

| Chemical Inertness | Resists corrosion and prevents fluid contamination. |

| Thermal Resistance | Maintains integrity across a wide temperature range. |

| Low Friction | Reduces buildup and is ideal for seals and gaskets. |

| Machinability | Allows for custom, precision components like seals and valve seats. |

Enhance your plumbing system's reliability and longevity with precision-machined PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, gaskets, and labware are engineered for superior performance. We specialize in transforming extruded PTFE rods into high-quality parts that resist harsh chemicals, withstand extreme temperatures, and reduce maintenance.

From initial prototypes to high-volume orders, KINTEK prioritizes precision production to meet your specific needs. Invest in the integrity of your fluid handling system – contact our experts today to discuss your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability