At their core, Teflon (PTFE) lip seals are high-performance components designed to operate reliably in extreme conditions that would cause traditional elastomeric seals to fail. They are engineered for applications involving high rotational speeds, significant pressures, wide temperature ranges, and aggressive chemical media, all while offering exceptionally low friction and long service life.

The essential value of a Teflon lip seal is its ability to provide a durable, low-friction seal in demanding operational environments. Its unique material properties make it the definitive choice when heat, speed, pressure, or chemical exposure exceeds the limits of standard rubber seals.

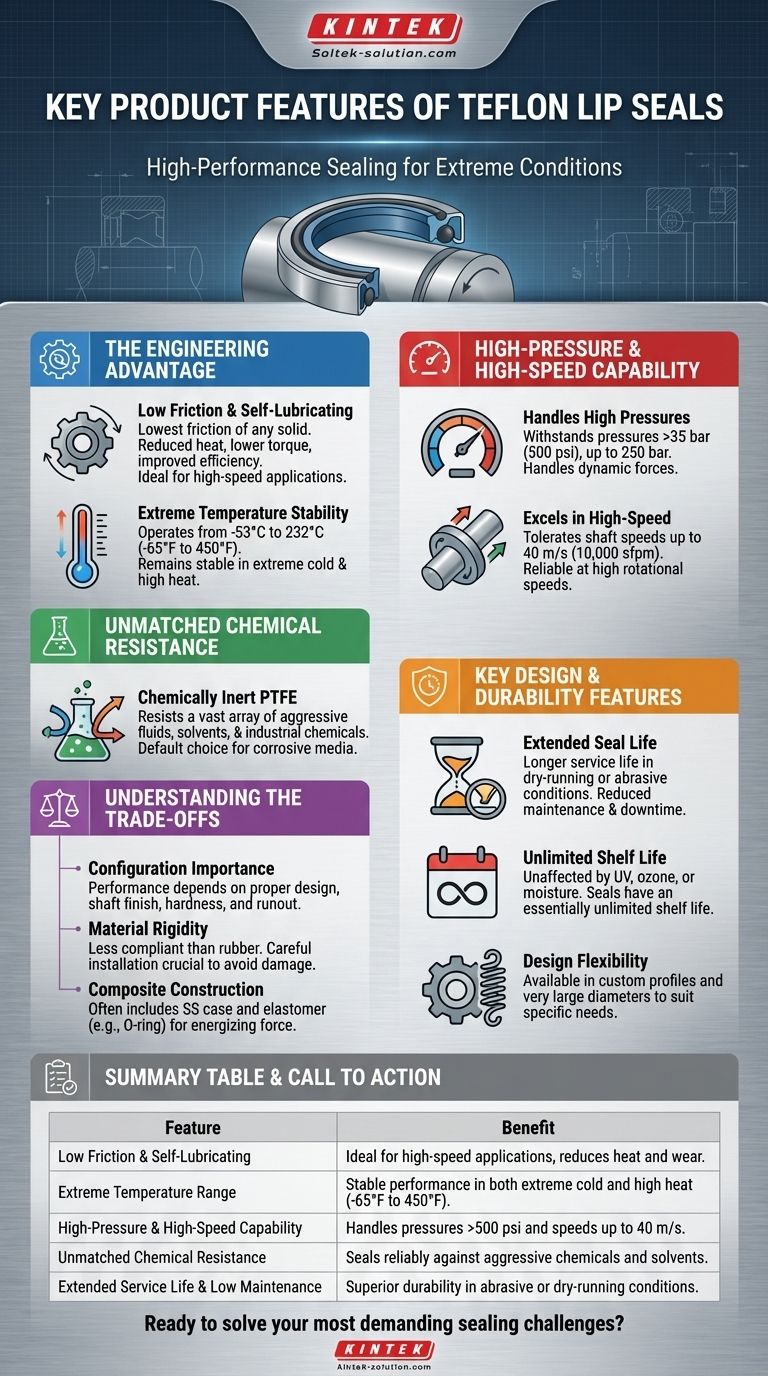

The Engineering Advantage of PTFE Seals

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a fluoropolymer with a unique combination of properties. When used as the primary sealing element, it creates a component with distinct operational advantages.

The Power of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is critical in high-speed applications.

Lower friction means less heat generation at the contact point, reducing the risk of seal degradation and shaft damage. This also results in lower torque requirements and improved energy efficiency.

Extreme Temperature Stability

Teflon seals function effectively across an exceptionally wide temperature range, typically from -53°C to 232°C (-65°F to 450°F).

This stability allows them to be used in systems with extreme cold start-ups or high operational heat, where conventional elastomers would become brittle or break down.

High-Pressure and High-Speed Capability

These seals are engineered to withstand significant dynamic forces. They can handle pressures in excess of 35 bar (500 psi), with certain designs rated for up to 250 bar.

Simultaneously, they excel in high-speed rotating applications, tolerating shaft surface speeds of up to 40 m/s (or 10,000 surface feet per minute).

Unmatched Chemical Resistance

PTFE is nearly chemically inert, resisting attack from a vast array of aggressive fluids, solvents, and industrial chemicals.

This makes Teflon seals the default choice for applications in chemical processing, pharmaceuticals, and any system where the media would corrode or swell standard rubber seals.

Understanding the Trade-offs

While powerful, Teflon seals are not a universal solution. Their unique properties come with specific design and application considerations.

Importance of Configuration

The performance and life of a PTFE seal are highly dependent on the proper configuration and design for the specific application. Factors like the shaft's surface finish, hardness, and runout are more critical than with forgiving elastomeric seals.

Material Rigidity

Compared to rubber, PTFE is a more rigid material. This means it is less compliant to imperfections in the housing or shaft. Careful installation is crucial to avoid damaging the seal lip and ensure proper function.

Composite Construction

To overcome PTFE's rigidity and provide energizing force, these seals are often composite designs. They typically incorporate a stainless steel (SS) case and an elastomer element, such as an O-ring, to press the PTFE lip against the shaft. This complexity can influence cost.

Key Design and Durability Features

The construction of these seals is tailored for longevity and reliability in challenging environments.

Extended Seal Life

The combination of low friction and high wear resistance provides a significantly longer service life, especially in dry-running or abrasive media applications.

This durability leads to reduced equipment downtime and minimal maintenance requirements over the seal's lifespan.

Unlimited Shelf Life

Unlike many elastomers that can degrade over time due to environmental exposure, PTFE is unaffected by UV light, ozone, or moisture. This gives the seals an essentially unlimited shelf life.

Design Flexibility

Teflon seals are available in a wide variety of custom profiles to suit specific needs, from pressure-actuated designs to spring-energized lips. They can also be manufactured in very large diameters, accommodating equipment of nearly any scale.

Making the Right Choice for Your Goal

Selecting a seal requires matching its strengths to your primary operational challenge.

- If your primary focus is high-speed rotation: The seal's exceptionally low friction will minimize heat generation and wear, protecting both the seal and the shaft.

- If your primary focus is high-pressure sealing: Choose a profile specifically designed to handle dynamic pressure without extrusion or leakage.

- If your primary focus is chemical compatibility: The inert nature of PTFE provides a reliable seal against nearly any aggressive fluid.

- If your primary focus is extended service life in abrasive conditions: The inherent toughness and wear resistance of PTFE will offer superior durability over traditional seals.

Ultimately, choosing a Teflon lip seal is a decision to invest in reliability for your most demanding applications.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Low Friction & Self-Lubricating | Ideal for high-speed applications, reduces heat and wear. |

| Extreme Temperature Range (-65°F to 450°F) | Stable performance in both extreme cold and high heat. |

| High-Pressure & High-Speed Capability | Handles pressures >500 psi and speeds up to 40 m/s. |

| Unmatched Chemical Resistance | Seals reliably against aggressive chemicals and solvents. |

| Extended Service Life & Low Maintenance | Superior durability in abrasive or dry-running conditions. |

Ready to solve your most demanding sealing challenges?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal engineered for reliability in your specific application.

Contact our experts today to discuss your requirements and discover how our PTFE seals can enhance your equipment's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments