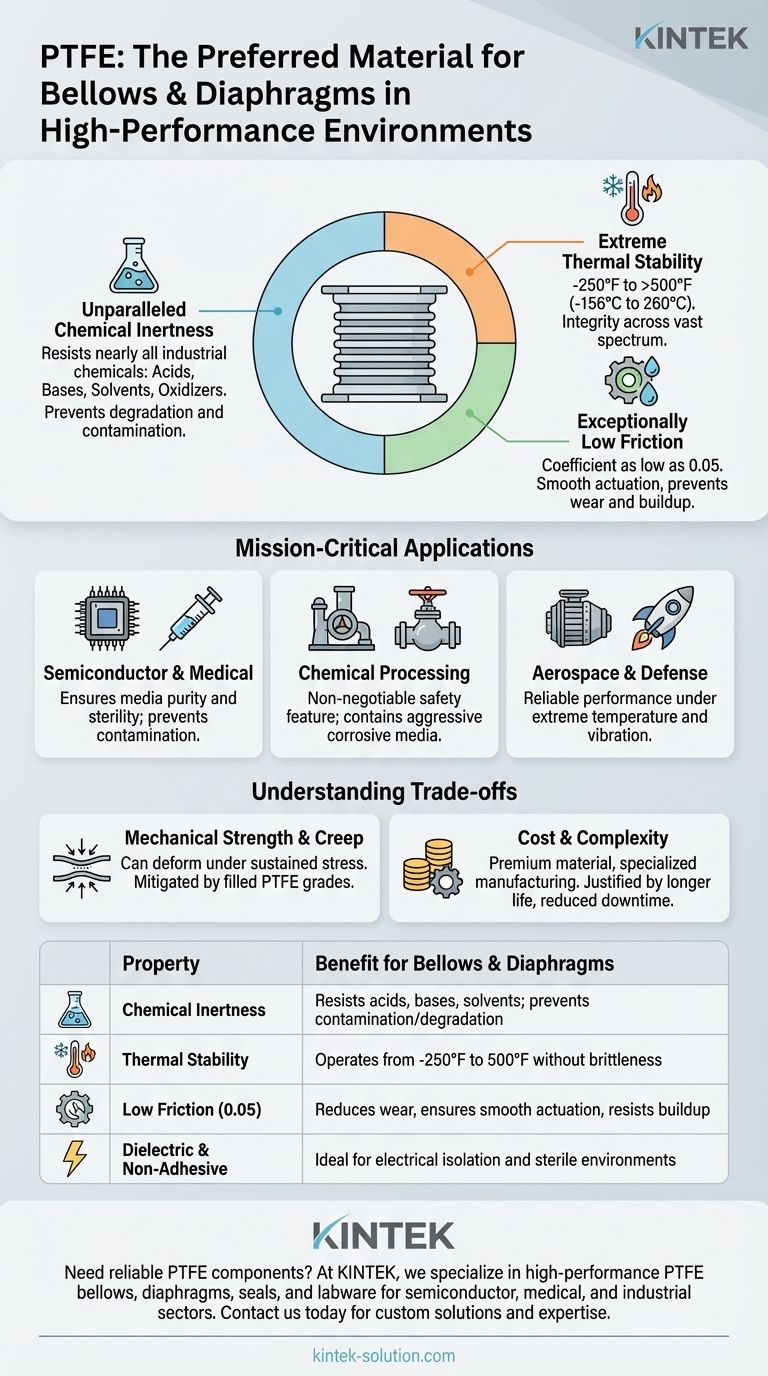

To put it simply, PTFE is the preferred material for high-performance bellows and diaphragms because of its extraordinary combination of properties. It possesses near-universal chemical inertness, operates reliably across an immense temperature range, and has an extremely low-friction surface, making it uniquely suited to survive in environments that would cause nearly any other material to fail.

The core reason for PTFE's dominance isn't just one superior property, but its unique ability to deliver chemical, thermal, and mechanical stability all at once. It functions as a reliable, flexible barrier in conditions where other polymers would degrade and metals would corrode.

The Core Properties Defining PTFE's Advantage

The value of PTFE (polytetrafluoroethylene) comes from a set of intrinsic characteristics that work together to ensure durability and predictable performance in dynamic, high-stress applications.

Unparalleled Chemical Inertness

PTFE is famous for being resistant to nearly all industrial chemicals, including aggressive acids, bases, solvents, and oxidizers.

This inertness is critical for bellows and diaphragms, which are often the only barrier separating a sensitive instrument or the external environment from corrosive process media. This property prevents both component degradation and contamination of the media.

Extreme Thermal Stability

PTFE maintains its integrity and flexibility across a vast temperature spectrum, typically from -250°F to over 500°F (-156°C to 260°C).

This allows it to be used in everything from cryogenic fluid systems to high-temperature chemical processing without becoming brittle or degrading, a range that few other flexible materials can match.

Exceptionally Low Friction

With a coefficient of friction comparable to wet ice on wet ice (as low as 0.05), PTFE surfaces are incredibly slick.

For dynamic components like bellows and diaphragms that must flex and move millions of times, this low-friction, non-stick surface prevents wear, ensures smooth actuation, and resists the buildup of process materials that could impede function.

Dielectric and Non-Adhesive Properties

PTFE is an excellent electrical insulator, making it ideal for applications requiring electrical isolation. Its non-adhesive surface also resists biofouling and contamination, which is crucial for sterile environments.

Where These Properties Are Mission-Critical

The theoretical benefits of PTFE translate directly into essential performance advantages across several demanding industries. These components are not just parts; they are engineered safety and reliability systems.

For Media Purity in Semiconductor and Medical

In semiconductor manufacturing and pharmaceutical production, even trace amounts of contamination can ruin an entire batch.

PTFE's inertness ensures no chemicals leach from the component into the process media. Its non-stick surface prevents cross-contamination between processes, guaranteeing the required purity and sterility.

For Operational Safety in Chemical Processing

Bellows and diaphragms are frequently used in pumps, valves, and pipeline systems containing highly corrosive or toxic chemicals.

Here, PTFE's chemical resistance is a non-negotiable safety feature. It provides a durable, flexible seal that contains aggressive media, protecting equipment, personnel, and the environment from hazardous leaks.

For Reliability in Aerospace and Defense

Components in aerospace applications must perform flawlessly under extreme temperature swings, high vibration, and exposure to specialized fuels and hydraulic fluids.

PTFE's combination of thermal stability and chemical resistance ensures that bellows and diaphragms function reliably, whether in deep space or in the high-temperature environment of an engine compartment.

Understanding the Trade-offs and Limitations

While PTFE is a superior material, it is not without limitations. Acknowledging its trade-offs is key to proper application engineering.

Mechanical Strength and Creep

Compared to metals, virgin PTFE is a relatively soft material. It can be susceptible to "creep," a slow deformation that occurs under sustained mechanical stress or pressure.

This can be mitigated by using filled PTFE grades, which incorporate materials like glass fiber or carbon to improve rigidity and wear resistance, though this can sometimes slightly reduce chemical compatibility.

Cost and Manufacturing Complexity

PTFE is a premium material, and manufacturing it into complex geometries like convoluted bellows is a specialized and often expensive process compared to molding common elastomers.

The higher initial cost is typically justified by longer service life, reduced downtime, and enhanced safety, resulting in a lower total cost of ownership in critical applications.

Gas Permeation

While it creates an excellent liquid barrier, PTFE is not entirely impermeable to all small-molecule gases.

In high-vacuum systems or applications requiring the containment of specific gases like helium, its permeation rate must be considered during the design phase.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary operational goal.

- If your primary focus is chemical purity and sterility: PTFE is the industry benchmark due to its unmatched inertness and non-contaminating surface.

- If your primary focus is resisting aggressive chemical corrosion: PTFE's near-universal chemical resistance makes it the safest and most dependable choice for containment.

- If your primary focus is high mechanical loads or pressures: Consider reinforced or filled PTFE grades for improved creep resistance, but verify their compatibility with your process media.

Ultimately, selecting PTFE is an investment in unparalleled reliability and operational safety for your most critical systems.

Summary Table:

| Property | Benefit for Bellows & Diaphragms |

|---|---|

| Chemical Inertness | Resists acids, bases, solvents; prevents contamination and degradation |

| Thermal Stability | Operates from -250°F to 500°F (-156°C to 260°C) without brittleness |

| Low Friction (0.05) | Reduces wear, ensures smooth actuation, and resists material buildup |

| Dielectric & Non-Adhesive | Ideal for electrical isolation and sterile environments |

Need reliable PTFE components for your critical applications? At KINTEK, we specialize in manufacturing high-performance PTFE bellows, diaphragms, seals, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication—from prototypes to high-volume orders—ensure your systems operate safely and efficiently. Contact us today to discuss your specific requirements and benefit from our expertise in material solutions that withstand the most demanding environments.

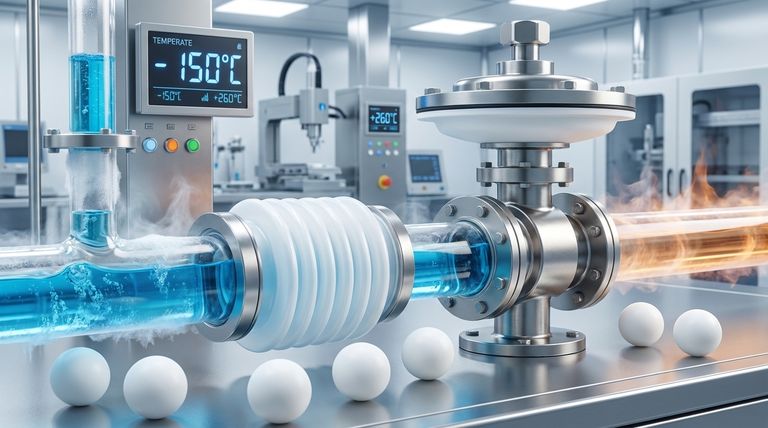

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application